3. Calculating Weight, Load and Length

16

PNEG-240

Chain Feeding System

Calculating the Load of the Entire System on the Structure

For calculating the load of the entire Chain Feeder System on the structure identify the following factors:

(1) The weight of suspended hoppers (use formula from

for calculations), (2) The length of trough

to be suspended, (3) The number of corners to be suspended, (4) The number of direct drive units to

be suspended.

Tabulate the weight of the Chain Feeding System to be suspended by inserting the quantity of each

component in the formula below.

HW

= Weight of hopper to be suspended (calculate weight using previous formula)

N

= Number of hoppers to be suspended

L

= Length of trough (in feet)

C

= Number of corners

D

= Number of single drive units

(

HW*N

) + (

L*

8.61) + (

C*

22.759) + (

D*

141.38) =

Weight of entire Chain Feeding System on the

Structure (pounds).

NOTE:

If more than one type of hopper is used in a structure, each hopper weight must be calculated and

inserted into the formula for entire weight of the Chain Feeding System.

NOTE:

Weight of feed calculated at 40 pounds per cubic foot. If feed to be used is a different density, the

weight of the system must be adjusted accordingly.

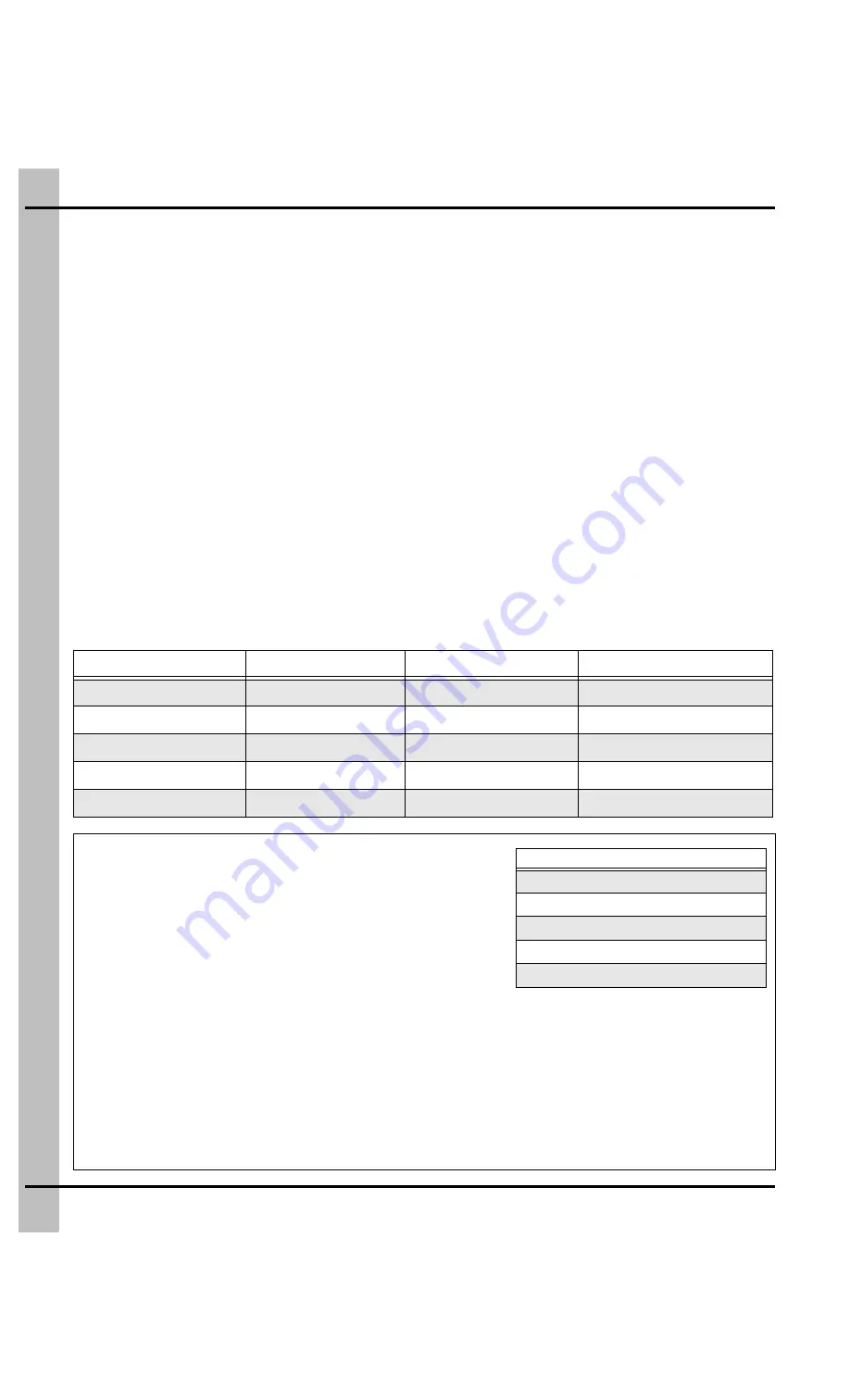

Motor Requirements

Length of Chain Circuit

Feed Delivery Rate

Belt Drive

Direct Drive

500' to 800'

120 Feet per Minute

3 HP-1725 RMP @ 60 Hz

2 HP-1725 RMP @ 60 Hz (Qty 2)

800' to 1000'

120 Feet per Minute

3 HP-1725 RMP @ 60 Hz

2 HP-1725 RMP @ 60 Hz (Qty 2)

Up to 500'

60 Feet per Minute

1-1/2 HP-1725 RMP @ 60 Hz 1-1/2 HP-1725 RMP @ 60 Hz

500' to 800'

60 Feet per Minute

2 HP-1725 RMP @ 60 Hz

2 HP-1725 RMP @ 60 Hz (Qty 2)

800' to 1000'

60 Feet per Minute

2 HP-1725 RMP @ 60 Hz

2 HP-1725 RMP @ 60 Hz (Qty 2)

T = Weight of trough per foot

C = Weight of chain per foot

F = Weight of feed per foot of trough

G = Weight of grill per foot

CU = Weight of coupler per foot of trough

Weight of trough per foot = T+C+F+G+CU*1.25

Weight of trough per foot

8.6075

Weight of direct drive unit = (Weight of direct drive + Weight of motor) * 1.25

Weight of corner = Weight of corner as Weight of feed

(15 + 3.236) * 1.25 = 22.759

1.85

0.8

3.236

0.8

0.2

*1.25

T = 1.85

C = 0.8

F = 3.236

G = 0.8

CU = 0.2

(75.6 + 37.50) * 1.25 = 141.38

Conversions

1 Inch = 25.4 mm

1 Foot = 0.3048 m

1 Yard = 0.9144 m

1 Ounce = 28.35 grams

1 Pound = 0.4536 kilograms