A. IMPORTANT WATER QUALITY ASSURANCE

REQUIREMENTS

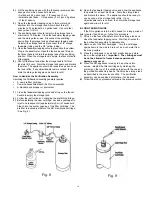

Reverse Osmosis drinking water appliances contain treat-

ment components that are critical for the effective reduction of

Total Dissolved Solids (TDS) as well as inorganic chemical

contaminants. Water Factory Systems

®

strongly recommends

that the user test the water periodically (every six months mini-

mum) to verify that the appliance is performing satisfactorily.

Some models have a Percent Rejection (PR) Water Quality

Monitor to provide the user with a means to test the water at

any time. If a PR Monitor is not used, your dealer will offer a

bi-annual water testing service. Routine maintenance is nec-

essary in the form of prefilter, postfilter, and membrane

replacement, based on the following guidelines:

•

Sediment, Carbon Prefilters, and Carbon Postfilters:

Change every six months to one year depending on the

feedwater quality.

•

RO Membrane: Change it as required based on a built-in

Percent Rejection (PR) Water Quality Monitor. A bi-annual

testing service will be offered by your dealer if a (PR)

Monitor is not used. The recommended maximum service

life is 36 months.

B. REPLACING THE FILTER CARTRIDGES

The life of the prefilter cartridge generally depends on the

local water conditions (i.e., dirt, rust and/or chlorine levels)

while the life of the postfilter cartridge(s) is generally deter-

mined by the length of service.

When to Replace the Sediment and Carbon Prefilter

Cartridge(s)

•

Every six months to one year, based upon your dealer's

recommendation and knowledge of the local water

conditions.

•

A noticeable decrease in water production is an indication

that the prefilter requires changing.

•

As a rule, private wells require more frequent sediment

prefilter changes while softened feed water usually requires

only yearly replacement.

•

Recommended maximum sediment or sediment/ carbon

prefilter service life is one year.

When to Replace the Carbon Postfilter Cartridge

•

If the filter is being used to control tastes and odors,

replace it every year.

•

If the filter is being used to reduce chloramines, change it

every six months. For critical applications such as

aquariums, base the filter change on periodic chloramine

(combined chlorine) tests.

•

If the filter is being used to meet standards for a regulated

organic chemical contaminant, then cartridge replacement

should be based on a monitoring program established with

a public health agency.

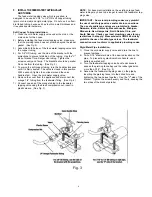

How to Replace the Prefilter and

Postfilter Cartridges

1)

Lift up on the faucet handle to drain the tank. Unplug the

transformer. Close the feedwater tapping valve. Wait five

(5) minutes for the purification assembly to completely

depressurize.

2)

Twist the filter cartridge 1/4 turn clockwise so that the ears

on the cartridge are able to disengage from the head.

Firmly pull the cartridge from the head. It may be

necessary to twist the cartridge slightly from side to side to

help free it.

3)

Remove the new filter cartridge from its sanitary sealed

wrapper. (Double check to see that it is the correct

replacement by comparing the labels.)

4)

Using tap water, food grade silicone lubricant or glycerin,

wet the o-ring seals to make cartridge insertion easier.

5)

Line up the cartridge ears, insert the cartridge and push it

into the head until it is fully seated. Twist the cartridge 1/4

turn counter-clockwise to lock it into place.

6)

Open the feedwater tapping valve, plug the transformer in

and carefully check for leaks.

II. Operation & Maintenance Instructions

12