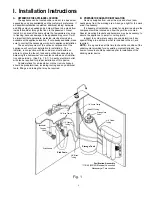

A. DETERMINE THE APPLIANCE LOCATION

The appliance can be located under a sink or in a basement

depending on space availability and the customer's preference. If

a basement installation is selected, additional tubing, hardware

and fittings may be needed and a hole will have to be made from

inside the cabinet, through the floor, to the basement. Never

install it in an area of the home where the temperature may drop

to freezing, because damage to the appliance may occur. It will

be important that appropriate, protected, electrical service be

available at the appliance location. If not already available, make

sure to contract the necessary work prior to appliance installation.

The exact placement of the various components of the

appliance will vary from installation to installation. The

installer, in conjunction with the customer, must decide on

where to place the faucet, tank and purification assembly by

balancing the homeowner's convenience with ease of installa-

tion and servicing. (See Fig. 1 & 7). A nearby electrical outlet

will also be required for proper installation of this device.

Considerations for an icemaker or other remote hookup

should be predetermined, including routing and any additional

tools, fittings, and tubing that may be required.

B. PREPARE THE AREA FOR INSTALLATION

Remove supplies from under the sink and stack them

neatly away from the working area. Arrange a light for the work

area, if necessary.

If a basement installation is called for, determine where the

components will be located and how they will be mounted.

Special mounting brackets and hardware may be necessary to

secure the appliance to a wall or ceiling joists.

Inspect the cold water supply line and determine if any

special fittings, in addition to what is included in the kit, are

required.

NOTE:

It is a good idea at this time to check the condition of the

undercounter plumbing for any existing or potential leaks. Any

items of concern should be repaired prior to installation of the

drinking water device.

I. Installation Instructions

3

Fig. 1

Storage Tank

Drain Saddle

Feedwater

Tapping

Valve

1/4” Orange

Tubing

3/8” Black

Tubing

3/8” Blue Tubing

1/4” Green Tubing

Red SFC Tubing

Storage Tank

Valve

3/8” Yellow

Tubing

Sink Drain

Purification Assembly

* 110/60 (220/50) Electrical Connection

Necessary at This Location