26

Установка

Instalación

Installation

Installation

Installation

EN

Transport

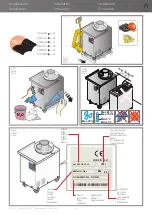

Fig.1.

Fitted with personal protection equipment, transport

the appliance to the installation location.

Use suitable equipment, capable of dealing with its weight:

persons not involved with the appliance installation may not

pass through or stand in the work area during the appliance

assembly.

During the transport, pay particular attention to passing through

openings and/or doors.

Model

rounding machine

weight

weight of

pac

rounding machine

Measurements

of the rounding

machine packaging

RND280

55 kg [121.2 lb]

64 kg [141 lb]

500 x 750 x 1000 mm

[19.69 x 29.53 x 39.37inc.]

RND800

86 kg [189.5 lb]

95 kg [209.4 lb]

Preliminary operations

Fig.2.

Carefully remove the protective film.

If any glue residue is left on the surfaces, remove it with soapy

water but without any corrosive or abrasive products or sharp or

pointed instruments.

Check that all the parts making up the product are in

good condition and without any faults or breakages, if

that is not the case, contact the Dealer for the procedures

to follow.

Positioning

Fig.3.

Install the appliance in a room:

• dedicated and suitable to the cooking of food;

• having adequate air ventilation;

• containing no flammable or explosive elements;

• that complies with the current regulations on health and

safety and systems in your country;

• is protected from the weather;

• has a maximum temperature of b5° (41°F) and

+35°C (95°F);

• has a maximum humidity of 70%.

Leave a free space of at least 20 cm between the appliance and

the walls of the room and/or other equipment to facilitate the

use, cleaning and maintenance of the machine itself.

To reduce the risk of a fire,

comply with the stated min-

imum distances

and install the appliances in

fireproof

rooms and

not at risk of explosion

. The floor of the in-

stallation room must also have a

fireproof

surface finish.

Serial number plate reading

Fig.4.

The serial number is on the back of the appliance.

It provides important technical information that is vital in case of

a request for maintenance or repair of the appliance: please do

not remove, damage or modify it.

Electrical connection

Before installing the appliance,

check that systems

comply with the regulations in force

in the country

where it is going to be used and

with the specifica-

tions indicated on the appliance rating plate

on the LH

side of the product.

• single-phase machines

have

the connection cable and the

plug already fitted

; for the connection, just insert the plug in

a socket of suitable capacity

Fig.5.

• three-phase machines

have

the power cable already in-

stalled; a plug (not supplied) must be fitted to it

of suit-

able capacity. This operation must be carried out by qualified

personnel.

For a correct electrical connection, the appliance must:

• be included in an

equipotential system

Fig.6.

in com-

pliance with the legislation in force. This connection must be

made between the various devices with the terminal marked

with the equipotential symbol

. The cable must have

a maximum cross-section of 10 mm

2

(in compliance with

IEC EN 60335-2-42:2003-09) and must be yellow-green;

• must be

grounded

to the mains (green-yellow wire);

• must be connected to a

circuit breaker

in compliance with

the regulations in force (0.03A A type);

• must be connected to an

omnipolar circuit breaker

allow-

ing complete disconnection in overvoltage III category con-

ditions.

The Manufacturer accepts no liability for failure to comply with

the above.

If required, the cable can be replaced by the Dealer or its

technical service or by a person with similar qualifications

to prevent any risk.

Model

Supply

V

Motor

kW

Absorbed

current

A

Cable type

n x mm

2

RND 280

AC 230V/50Hz

0.37 kW

2.7

3x1.5

AC 3 N 400V/50Hz

0.37 kW

1.8

4x1.5

RND 800

AC 230V/50Hz

0.37 kW

2.7

3x1.5

AC 3 N 400V/50Hz

0.37 kW

1.8

4x1.5

Pre-testing and final inspection

The product is checked and tested in the Manufacturer’s plant

before being delivered to the customer.

The “production process check sheet” enclosed with it guaran-

tees that each step in the production process, from assembly to

packaging, was carefully checked from both the operating and

safety standpoints.

Operations to carry out before delivery of the product to the

customer:

•

Check the installation is correct;

•

Start the appliance

following the instructions in the “Use and

Maintenance” manual annexed: monitor it during the whole

test and check that all the electrical components work properly.

• At the end of the test, you

MUST

activate the guarantee.

IF NOT REGULARLY ACTIVATED, THE VALIDI-

TY OF THE SAME STARTS FROM THE INVOICE

DATE AND NOT FROM THE ACTUAL INSTALLA-

TION DATE.

•

Provide the user with all the information

on the correct

and safe use of the appliance.

Installazione