20

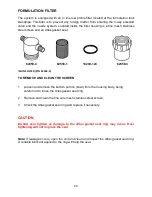

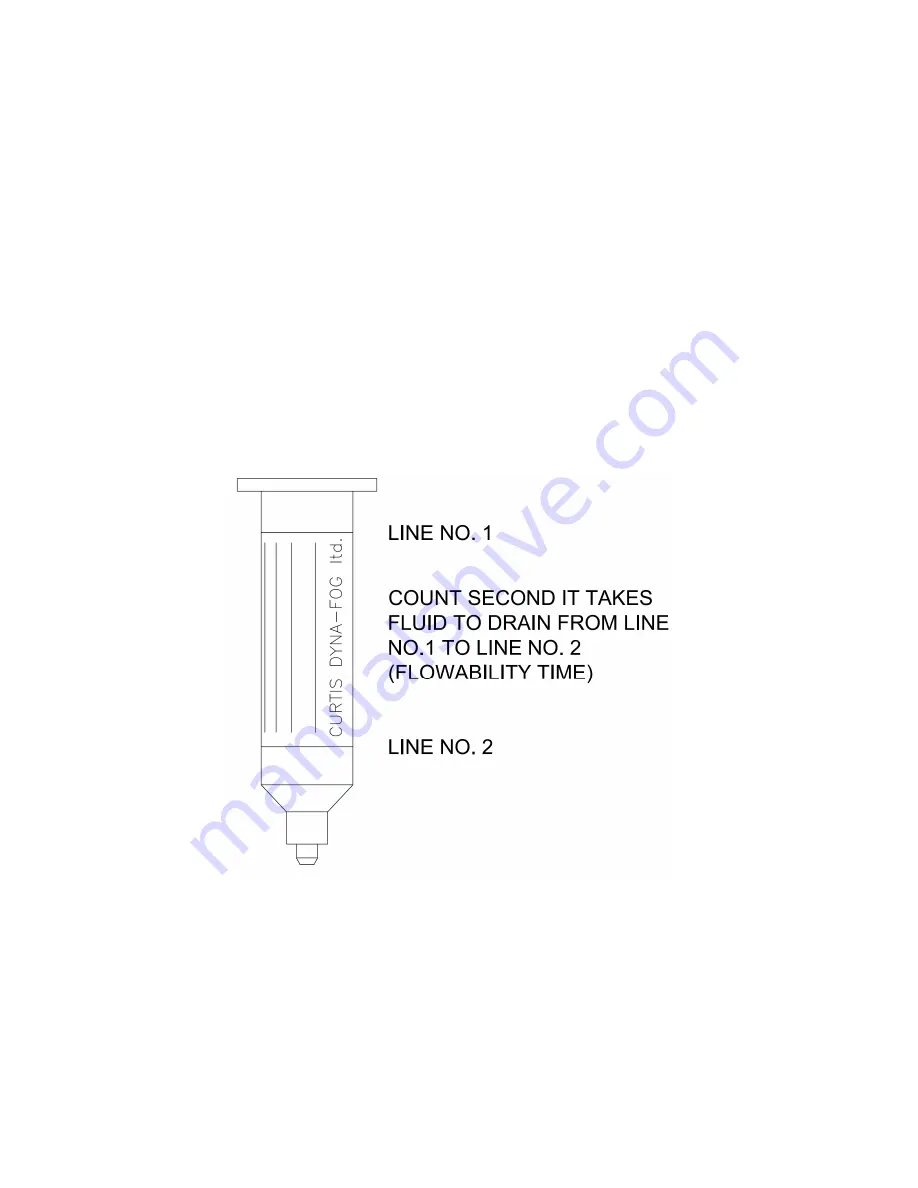

To measure the flow ability (viscosity) of your formulation:

1. Place a sample of the formulation liquid to be dispensed in the relative viscosity

meter provided with the machine such that the liquid level is above the top line.

2. Hold the meter vertical and allow the liquid to flow through the brass orifice at the

outlet end of the meter into an appropriate container.

3. Using a stopwatch or a watch with a sweep second hand, determine the flow

ability time in seconds that it takes for the liquid level to fall from the top line to the

bottom line.

Once the flow ability of the liquid has been measured, tables 1 and 2 can be used as an

approximate guide for setting the pump flow rate and nozzle boom pressure for your

spray application.

NOTE: Periodically calibrate the flow ability meter using plain water. Water should flow

through the orifice such that the time between the top line and the bottom line is

32 + 2 seconds.

CAUTION

Follow all warnings and cautions on your formulation label. Do not attempt to

apply any formulation at a rate greater than what is specified on the formulation

label. This includes driving your vehicle at a rate slower than what is specified.

Summary of Contents for MAXI-PRO 2D ULV

Page 6: ...6 MAJOR COMPONENTS DIAGRAM ...

Page 9: ...9 ...

Page 39: ...39 ...

Page 43: ...43 BOOM ASSEMBLY MAXI PRO 2D P N 64905 ...

Page 50: ...50 ...