23

SYNCROFLOW SYSTEM

When equipped, the Curtis Syncroflow System allows the dispensing of formulation to

be either a constant flow ("manual") regardless of vehicle speed, or a variable flow

("syncroflow") which is correlated to vary proportionately with vehicle speeds from 0 to

20 m.p.h. (0-32.2 km/hr)

Either system can be actuated by a toggle switch located in the side of the pump control

box which is

l

ocated on the pump enclosure.

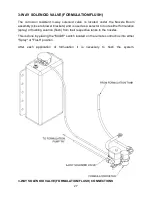

When the syncroflow system is actuated, electronic pulses are fed from the

speedometer transmission transducer to the formulation pump. As the vehicle moves

faster or slower these pulses increase or decrease in frequency which in turn cause the

formulation output pump to increase or decrease the fluid flow.

SPRAYING – SYNCROFLOW

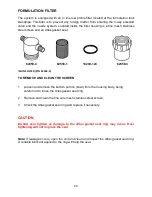

1. Place the formulation to be used in the formulation container.

CAUTION

Carefully read the formulation label for safety precautions and app

l

ication rate.

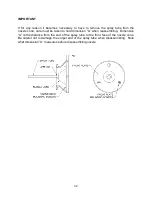

2. Ensure that all switches on the remote control box are in the OFF position.

3. Place the MANUAL - SYNCROFLOW toggle switch which is located on the

formulation pump control box into the Syncroflow position.

4.

If the required Output rate if 0.3 to 1.8 ounces per minute (9 ml/min to 54 ml/min),

contact the factory to set the rate range connections in the chassis interface

boxto the LOW position, then place the Function Select switch remote control

box in either position 1 or 3 as appropriate. If the required Output rate is 1.8 to 18

ounces per minute (standard factory setting in the pump control box), place the

Rate Range switch in the HIGH position and the Function Select switch in

position 2 or 4 as appropriate.

5.

Place the MACHINE switch on the remote control box in the ON position.

6.

Place the RUN-STOP (ON-OFF) switch located on the engine in the RUN (ON)

position and start the engine (see STARTING ENGINE section).

7.

Place the MODE switch on the remote contro

l

box in the SPRAY position.

8.

Observe that, the MACHINE light and the SPRAY light are ON and the FLUSH,

OUTPUT and FAULT Sights are not ON.

9.

The digital rate readout should read zero.

10.

Start the vehicle in motion and place the OUTPUT switch on the ON position.

Summary of Contents for MAXI-PRO 2D ULV

Page 6: ...6 MAJOR COMPONENTS DIAGRAM ...

Page 9: ...9 ...

Page 39: ...39 ...

Page 43: ...43 BOOM ASSEMBLY MAXI PRO 2D P N 64905 ...

Page 50: ...50 ...