KEY FEATURES/SPECIFICATIONS/SYSTEM REQUIREMENTS

FS42

Key Features

• G3 Digital Control Module - Provides precise control over all critical blending and dispensing functions.

• Factory Pre-Set - For out-of-the-box operation.

•

4DSPMM5ISPVHI1SFDJTJPO1SPHSBNNJOH"EKVTUQPXEFSnPXJOJODSFNFOUTBOEXBUFSUFNQFSBUVSFGSPN

80°F (27°C) to 204°F (96°C) to create the perfect hot or cold beverage.

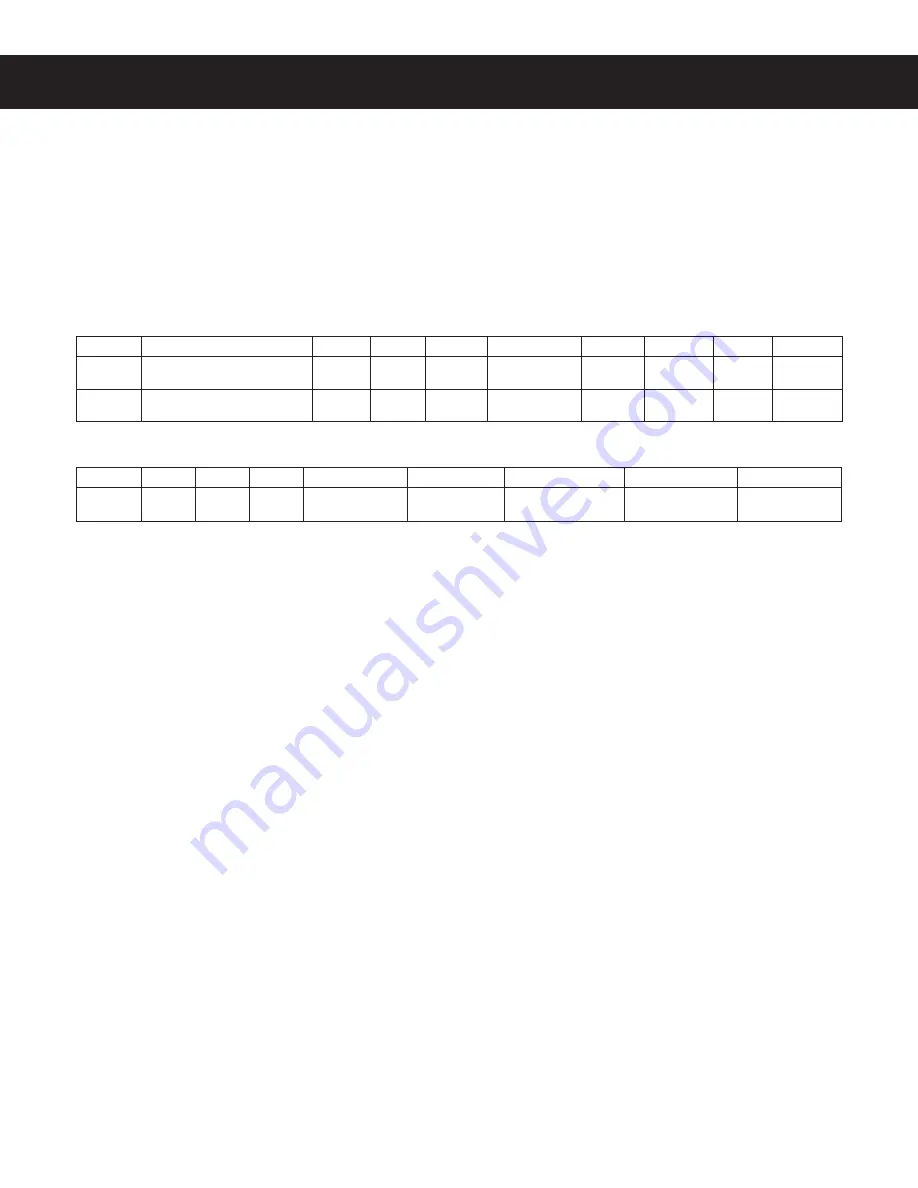

6SHFLÀFDWLRQV6HOHFWHG0RGHOV

(OHFWULFDO6XSSO\5HTXLUHPHQWV

02'(/

'(6&5,37,21

3+$6(

92/76

$036

+($7,1*&21),*

:,5(

:$776

+(57=

&$3$&,7<

3&*7

6 Station

1 PH

120 V

15.0 A

1 x 1600 W

2W + G

1800 W

50/60 Hz

5.3 gal/hr

[20.1 l/hr]

3&*7

6 Station with lift door

1 PH

120 V

15.0 A

1 x 1600 W

2W + G

1800 W

50/60 Hz

5.3 gal/hr

[20.1 l/hr]

'LPHQVLRQV

:DWHU6XSSO\5HTXLUHPHQWV

02'(/

+(,*+7

:,'7+

'(37+

6+,3:(,*+7

6+,3&8%(

:$7(5&211(&725

:$7(535(6685(

0,1)/2:5$7(

3&*7

3&*7

34.78”

[88.3 cm]

20.86”

[53.0 cm]

24.54”

[62.3 cm]

160.0 lbs

[72.6 kg]

22.92 cu. ft.

[0.65 m

3

]

µÁDUH

20 - 90 psi

[138 - 620 kPa]

1.0 gpm

[3.8 lpm]

PCGT6, KEY FEATURES/SPECS/SYSTEM REQUIREMENTS

100319C

Following are the factory default settings for the Primo Cappuccino

™

dispenser:

•

1PXEFS3BUJP

• Water Temperature = 190°F (88°C)