Curtis Front End Loader Blade (F.E.L.B.) Assembly Instructions (continued)

7.)

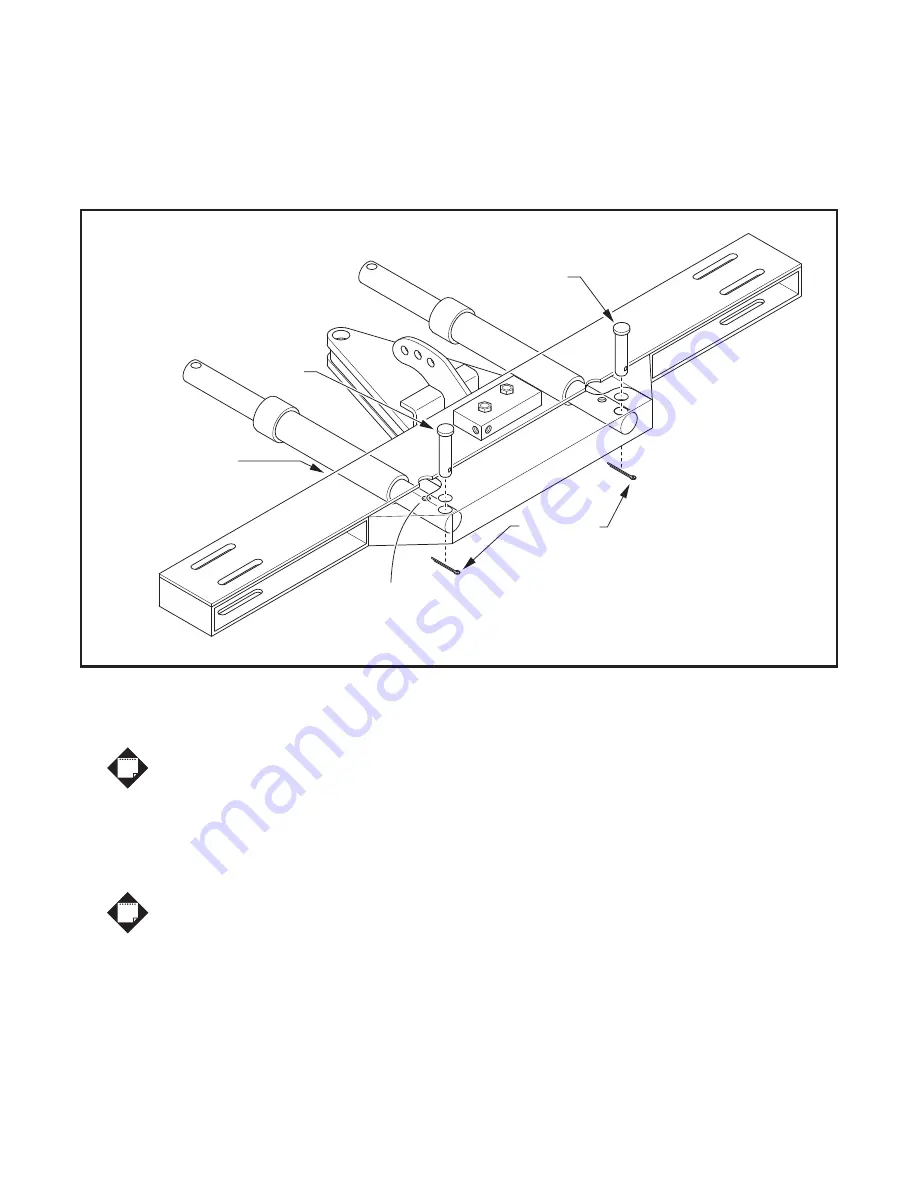

Locate both 10" Angle Cylinders (1TBP27) and mount one to each side of the A-Frame. The Angle Cylinders

will be inserted into the A-Frame at the front through the slots, with the Hydraulic Port facing up and visible

through the opening at the top of the A-Frame. Mount each Angle Cylinder to the A-Frame with a 1" x 3" Clevis

Pin (1TBP73) and secure each Clevis Pin with a 3/16" x 1-1/2" Cotter Pin (1TBP24). Refer to Figure 8.

8.)

Lift the A-Frame above the Trip Frame, and insert the A-frame and Angle Cylinders into the Trip Frame.

Apply grease to the 1"-8 x 6" Gr.5 Center Bolt (1TBP25) and insert through the Trip Frame and A-Frame.

Secure the Center Bolt with a 1" Nylon Lock Nut (1TBP26). Refer to Figure 9.

Do not over tighten the Nylon Lock Nut, the A-Frame must pivot freely.

9.)

Swing A-Frame to Left or Right and align hole in Angle Cylinder Ram with the corresponding hole in Trip

Frame. Install (1) 1" x 4" Clevis Pin (1TBP23) through Trip Frame and Angle Cylinder Ram.

Secure Clevis Pin with (1) 3/16" x 1-1/2" Cotter Pin (1TBP24). Swing A-Frame to opposite side and

repeat alignment and pinning procedure. Swing A-Frame back to the center.

It may be necessary to extend the Angle Cylinder Piston Rod 1-2" to make

the connection to the Trip Frame. To do this, insert a long pin or ratchet handle

through the Piston Rod and work the piston Rod side to side while pushing downward.

10.)

Return the A-Frame to the center position after the Angle Cylinders are secured to the Moldboard.

Using the A-Frame as a lever, grasp the A-Frame by the cross-brace and pull back, raising the Moldboard

to a vertical position.

Figure 8. Mount Angle Cylinders to A-Frame

1" x 3"

Clevis Pin

1" x 3"

Clevis Pin

Angle Cylinders are

inserted into slots in

the front of A-Frame

3/16" x 1-1/2"

Cotter Pins

install from

below

Hose Ports up

NOTE

NOTE

7 of 14