WARNING

THIS ANTENNA IS AN ELECTRICAL CONDUCTOR. CONTACT WITH POWER LINES CAN RESULT IN DEATH, OR SERIOUS INJURY.

DO NOT INSTALL THIS ANTENNA WHERE THERE IS ANY POSSIBILITY OF CONTACT WITH OR HIGH VOLTAGE ARC-OVER FROM

POWER CABLES OR SERVICE DROPS TO BUILDINGS. THE ANTENNA, SUPPORTING MAST AND/OR TOWER MUST NOT BE

CLOSE TO ANY POWER LINES DURING INSTALLATION, REMOVAL OR IN THE EVENT PART OF THE SYSTEM SHOULD ACCIDENTALLY

FALL. FOLLOW THE GUIDELINES FOR ANTENNA INSTALLATIONS RECOMMENDED BY THE U.S. CONSUMER PRODUCT SAFETY

COMMISSION AND LISTED IN THE ENCLOSED PAMPHLET.

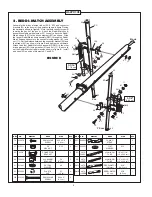

A627013S

1

Your Cushcraft VHF/UHF antenna is designed and manufactured to give top performance and trouble free service. The antenna will perform

as specified if the instructions and suggestions are followed and care is used in assembly and installation. When checking the components

received in your antenna package use the parts lists in each section. It is easiest to identify the various dimensions of tubing by separating

them into groups of the same diameter and length. If you are unable to locate any tube or component, check the inside of all tubing.

IMPORTANT: save the weight label from the outside of the carton. Each antenna is weighed at the factory to verify the parts count. If you

claim a missing part, you will be asked for the weight verification label.

There is a master parts list on page 2.

LOCATION

Location of the antenna is very important. Surrounding objects such as trees, power lines, other antennas, etc. will seriously reduce efficiency.

To minimize the effects of surrounding objects, mount the antenna as high and in the clear as possible. If metal guy wires are used, they

should be broken with strain insulators. YOU MUST INSURE THAT PEOPLE CANNOT COME IN CONTACT WITH YOUR ANTENNA

WHILE IT IS IN OPERATION. DEADLY VOLTAGES AND CURRENTS MAY EXIST. ALSO, SINCE THE EFFECTS OF EXPOSURE TO

RF ARE NOT FULLY UNDERSTOOD, LONG TERM EXPOSURE TO INTENSE RF FIELDS IS NOT RECOMMENDED. THERE IS A

WARNING STICKER WHICH MUST BE ATTACHED TO THE boom as shown in figure 4.

Plan your installation carefully. If you use volunteer helpers be sure that they are qualified to assist you. Make certain that everyone involved

understands that you are in charge and that they must follow your instructions. If you have any doubts at all employ a professional antenna

installation company to install your antenna.

MOUNTING

The A627013S mast mount bracket will take up to a 2" (5.1 cm) O.D. mast. A 1-1/4" (3.17 cm) television type tubing is satisfactory for a

single A627013S beam. A good heavy-duty antenna rotator will provide the best service and longest life. Often it is desirable to mount

several antennas on one mast. To keep possible interaction to minimum, place your antennas as far apart as you can.

SYSTEM GROUNDING

Direct grounding of the antenna, mast and tower is very important. This serves as protection from lightning strikes, static buildup and high

voltage which is present in the radio equipment connected to the antenna. A good electrical connection should be made to one or more

ground rods (or other extensive ground system) directly at the base of the tower or mast, using at least #10AWG ground wire and non-

corrosive hardware. For details and safety standards, consult the National Electrical Code. You should also use a coaxial lightning arrester.

Cushcraft offers several different models, such as LAC-1, LAC-2 and the LAC-4 series.

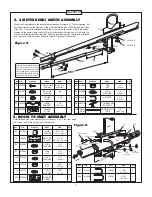

ASSEMBLY

Assemble your antenna by following the directions and illustrations in steps 1 through 7. After the antenna is completely assembled, verify

dimensions and element spacings for accuracy. Then, return to the section below for final tuning.

TUNING PROCEDURE

The A627013S does not normally require tuning after assembly.

Due to the difficulty in adjusting the tuning without the proper test

equipment, we do not advise adjusting either of the Reddi-Match straps. Please use the factory specified settings. An VSWR of

2:1 or less is sufficient.

However, if you wish to check the VSWR before installation, please observe the following procedures. To prevent

detuning the antenna, it should be tuned in place or at least 7 feet (2.1 m) above ground and clear of surrounding objects. Keep all metal

obstructions such as guy wires and other antennas at least 7 feet (2.1 m) away since they will nullify any adjustment and degraded performance

will result.

Run the coax cable from your transmitter to the area in which the antenna is going to be tested. The length of this cable or your feedline

is not critical. Connect a good quality VSWR bridge to the end of this cable. Connect a short length of cable [10 ft (3 m) or less] from the

VSWR bridge to the antenna. Set the transmitter to your center operating frequency. When you read VSWR, be sure you move far enough

away from the antenna so that your body does not effect the reading.

Note: The feedline harness (FL) for 2m/70cm must be connected to

both driven elements for proper match. Do not attempt to match separately since the two driven elements interact.

Measure the VSWR. If it is greater than 2:1, move the tuning strap for that band by 1/8" (.3 cm) in one direction and check the VSWR. If

the VSWR improves, continue moving the tuning strap in the same direction. If the VSWR deteriorates then move the tuning strap in the

opposite direction. Repeat this procedure until no further improvement can be made. Alternate between adjusting both 2m and 70cm until

an SWR of 2:1 or better is achieved on both bands. You have matched your antenna to 50 Ohms. Note that both driven elements will have

a slight interaction when adjusted for best match. Very little improvement in performance will result from a match better than 2:1 VSWR.

Tighten all connections making sure to keep the Reddi-Match assembly parallel to the elements (EC & ED). Tape the feedlineharness to

the boom and mast (figure I).