ELECTRIC THREE WHEEL SERVICE VEHICLE

Page 8

Owner’s Manual and Service Guide

Read all of manual to become familiar with this vehicle. Pay attention to all NOTICES, CAUTIONS,WARNINGS and DANGERS.

Fig. 14). Refer to Lubrication Points for appropriate lubri-

cation locations (Ref Fig. 8).

Some maintenance items must be serviced more frequently on

vehicles used under severe driving conditions.

Use maximum of three pumps of grease for each

grease fitting - Overgreasing may damage grease

seals.

Putting more than three pumps of grease in a grease fit-

ting could damage grease seals and cause premature

bearing failure.

REAR AXLE

The only maintenance required for the first five years is

the periodic inspection of the lubricant level. The rear

axle is provided with a lubricant level check/fill plug

located on the bottom of the differential. Unless leakage

is evident, the lubricant need only be replaced after five

years.

Checking the Lubricant Level

With the vehicle on level ground, clean the area around

the check/fill plug and remove plug (Ref Fig. 9). The cor-

rect lubricant level is just below the bottom of the

threaded hole. If lubricant is low, add as required. Add

lubricant slowly until lubricant starts to seep from the

hole. Install the check/fill plug. In the event that the lubri-

cant is to be replaced, the vehicle must be elevated and

the oil pan removed or the oil siphoned out through the

check/fill hole.

NOTICE

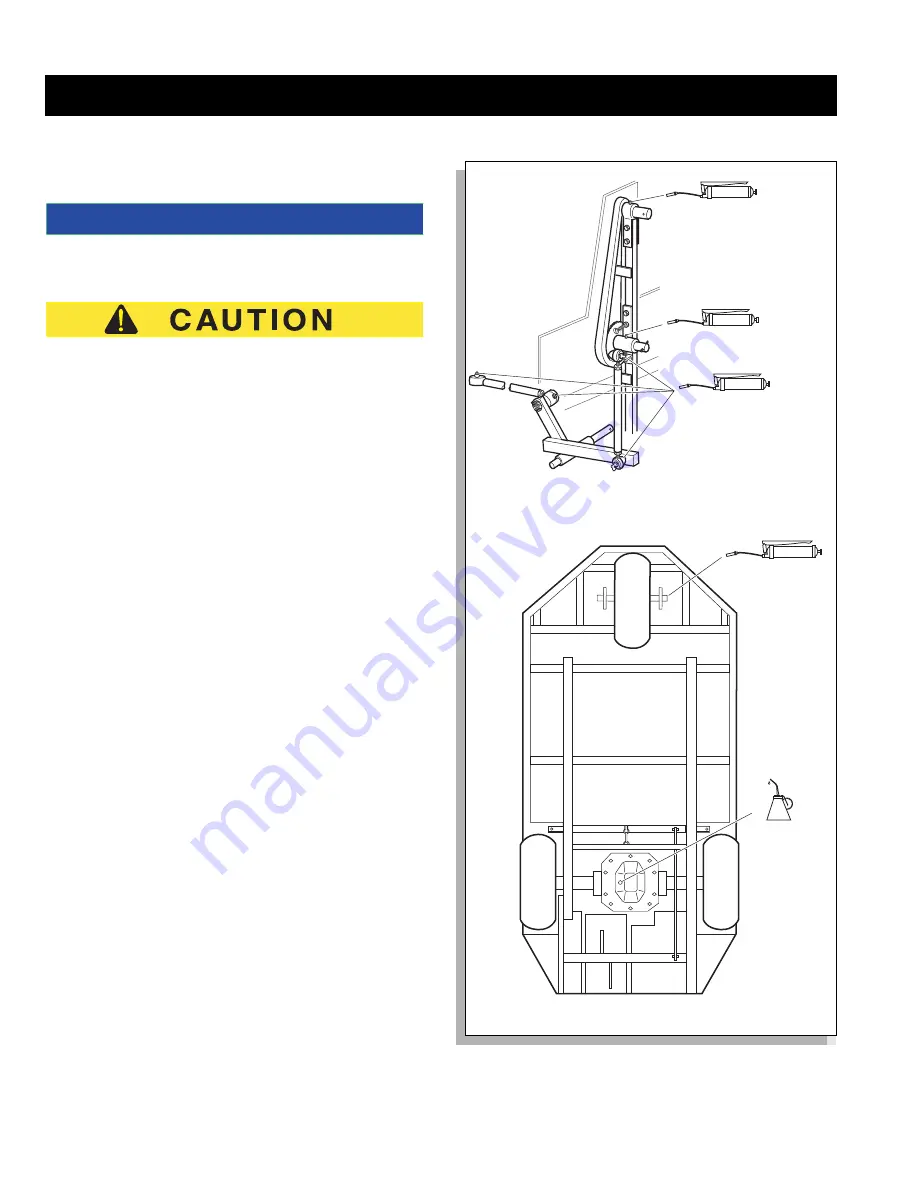

Fig. 8 Lubrication Points

Wheel bearings

and fork pivot

View from underside of vehicle

Steering with steering wheel and

cover removed for clarity

Rear axle

check and

fill

4 Ball Joints

Grease Fitting

Grease Fitting