ELECTRIC THREE WHEEL SERVICE VEHICLE

Page 11

Owner’s Manual and Service Guide

Read all of manual to become familiar with this vehicle. Pay attention to all NOTICES, CAUTIONS,WARNINGS and DANGERS.

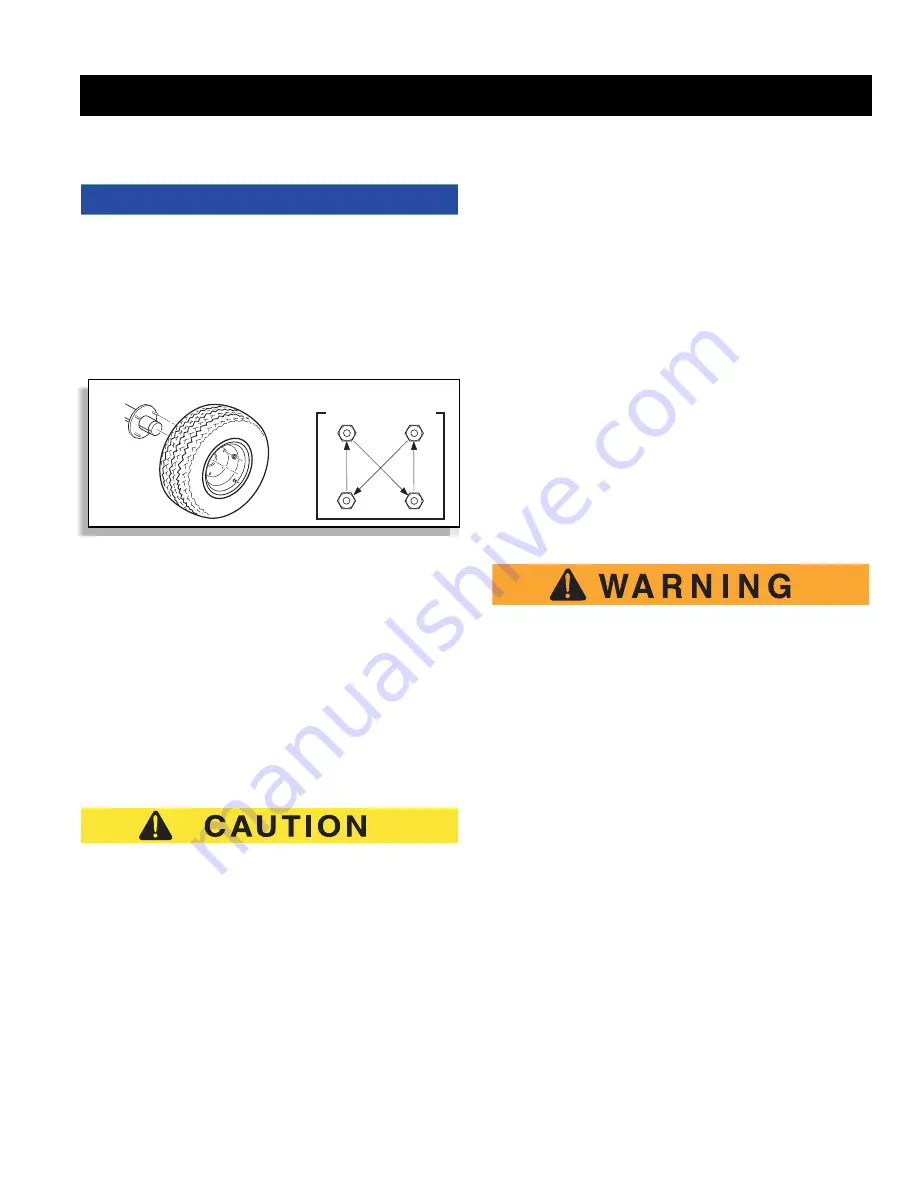

It is important to follow the ‘cross sequence’ pattern when

installing lug nuts. This will assure even seating of the wheel

against the hub.

With the valve stem to the outside, mount the wheel onto

the hub with lug nuts. Finger tighten lug nuts in a ‘cross

sequence’ pattern (Ref Fig. 11). Then, tighten lug nuts to

50 - 85 ft. lbs. (70 - 115 Nm) torque in 20 ft. lbs. (30 Nm)

increments following the same ‘cross sequence’ pattern.

LIGHT BULB REPLACEMENT

To replace the headlight bulb, pivot the headlight forward

and remove the two Phillips head screws from back side

and separate light assembly. Place new light bulb in

place and secure with screws previously removed.

To replace the taillight bulb, remove hardware securing

lens and remove lens. Install replacement bulb.

CARE AND CLEANING OF THE

VEHICLE

To prevent cosmetic damage, do not use any abra-

sive or reactive solvents to clean plastic parts.

It is important that proper techniques and cleaning mate-

rials be used.

Normal cleaning of the vinyl backrest and plastic or rub-

ber trim requires the use of a mild soap solution applied

with a sponge or soft brush and wipe with a damp cloth.

Removal of oil, tar, asphalt, shoe polish, etc. will require

the use of a commercially available vinyl/rubber cleaner.

The painted surfaces of the vehicle provide attractive

appearance and durable protection. Frequent washing

with lukewarm or cold water is the best method of pre-

serving the painted surfaces.

Do not use hot water, strong soap or harsh chemical

detergents.

Rubber parts should be cleaned with nonabrasive house-

hold cleaner.

Occasional cleaning and waxing with nonabrasive prod-

ucts designed for ‘clear coat’ automotive finishes will

enhance the appearance and durability of the painted

surfaces.

Corrosive materials used for dust control can collect on

the underbody of the vehicle. These materials will accel-

erate corrosion of underbody parts. It is recommended

that the underbody be flushed occasionally with plain

water. Thoroughly clean any areas where mud or other

debris can collect. Sediment packed in closed areas

should be loosened to ease its removal, taking care not

to chip or otherwise damage paint.

TRAILERING

To prevent personal injury to occupants of

other highway vehicles, be sure that the

v e h i c l e a n d c o n t e n t s a r e a d e q u a t e l y

secured to trailer.

Do not ride on vehicle being trailered.

Always check that the vehicle and contents are ade-

quately secured before trailering the vehicle. The rated

capacity of the trailer must exceed the weight of the vehi-

cle and load plus 400 pounds (see GENERAL SPECIFI-

CATIONS section for vehicle weight). Secure the vehicle

to the trailer using ratchet tie downs.

HARDWARE

Periodically, the vehicle should be inspected for loose

fasteners. Fasteners should be tightened in accordance

with the Torque Specifications table (Ref Fig. 13). Use

care when tightening fasteners and refer to the Techni-

cian’s Repair and Service Manual for specific torque val-

ues.

Generally, two grades of hardware are used in the vehi-

cle. Grade 5 hardware can be identified by the three

marks on the hexagonal head. Unmarked hardware is

Grade 2 (Ref Fig. 12).

Fig. 11 Wheel Installation

NOTICE

Tire style

may vary

1

2

3

4

'Cross Sequence'