5 - 17

MAINTENANCE

Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers.

5

As a final check, check the oil level again with the vehicle on level ground. Like all liquids, oil increases in volume

when warm. The full ‘H’ mark on the dipstick is calibrated for an engine at operating temperature. When the engine is

cold, the oil will be below the full mark. The engine can be operated safely as long as the oil is within the safe oper-

ating range as indicated on the dipstick.

Do not operate vehicle if oil level is below the safe area indicated on

the dipstick.

STARTER/GENERATOR BELT TENSION

Tool List

Qty.

Belt tension gauge ..................................................................................................................................................1

Wrench, 3/4" ...........................................................................................................................................................1

Wrench, 9/16" .........................................................................................................................................................2

Ratchet, 3/8" drive...................................................................................................................................................1

Socket, 3/4", 3/8" drive............................................................................................................................................1

The starter/generator belt tension should be checked after the first 15 - 20 hours and set to 75 - 80 lbs. (34 - 36 kg).

At no time during installation of belt, should the belt tension exceed 160 lbs (73 kg).

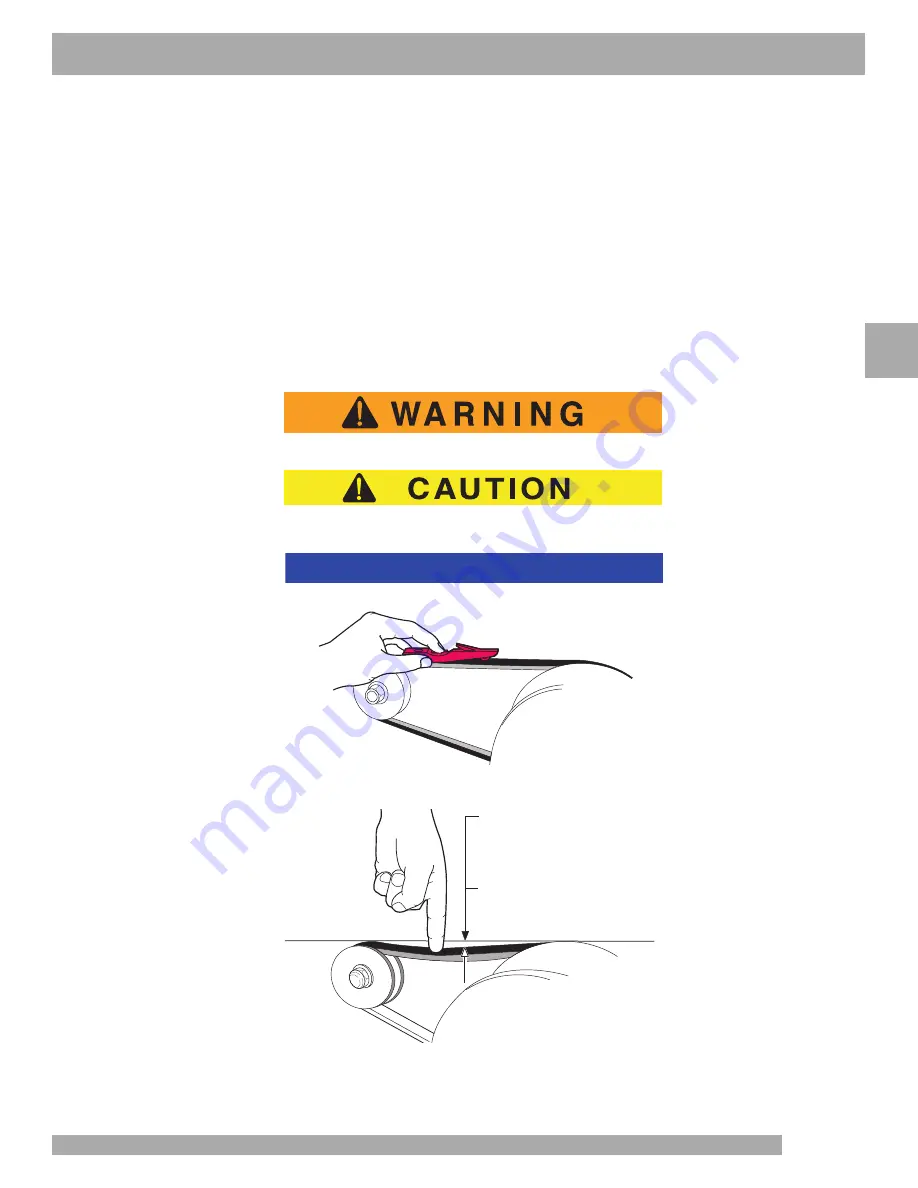

At the time of installation, the belt must not be rolled over the installed edges of the starter/generator or drive clutch

pulleys. Excessive stretch in belt may cause cord failure.

A loose belt can cause audible vibration and squeal.

Tighten a

new

starter/generator belt to 110 - 130 lbs. (50 - 59 kg) tension when a gauge is applied half way between

the two pulleys.

A

new

belt may be checked manually. A maximum deflection of 3/8" (10 mm) is acceptable. Tighten an

existing

belt

to 75 - 80 lbs. (34 - 36 kg) tension using the same technique and inspect for cracking or wear. A maximum deflection

of 1/2" (13 mm) is acceptable.

NOTICE

3/8" (1 cm) Maximum

Deflection (New Belt)

1/2" (1.3 cm) Maximum

Deflection (Existing Belt)