6.2 Planning of cleaning operations

The regular cleaning of the device keeps the print quality and extends its life. The following table shows the recommended

planning for the cleaning operations.

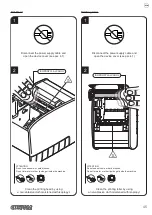

EVERY PAPER CHANGE

Printhead

Use isopropyl alcohol

Rollers

Use isopropyl alcohol

EVERY 5 PAPER CHANGES

Cutter

Use compressed air

Paper path

Use compressed air or tweezers

Sensors

Use compressed air

EVERY 6 MONTHS OR AS NEEDED

Printer case

Use compressed air or a soft cloth

For speciic procedures, see the following pages.

NOTE: If you use the device in dusty environments, you must reduce the intervals between the cleaning operations.

43

Summary of Contents for Kube II

Page 1: ...CUSTOM S p A USER MANUAL KUBE II ...

Page 2: ......

Page 5: ...MANUAL For details on the commands refer to the manual with code 77200000001000 ...

Page 6: ......

Page 10: ...10 ...

Page 18: ...18 ...

Page 22: ...Fix the device to the wall 9 22 ...

Page 28: ...28 ...

Page 32: ...32 ...

Page 60: ...60 ...

Page 62: ...62 ...

Page 65: ...5 Reassemble the carter sliding it in the direction indicated 65 ...

Page 66: ...66 ...

Page 76: ...76 ...

Page 78: ...78 ...

Page 79: ......