CC650

Production / Industrial Hose Crimper

13

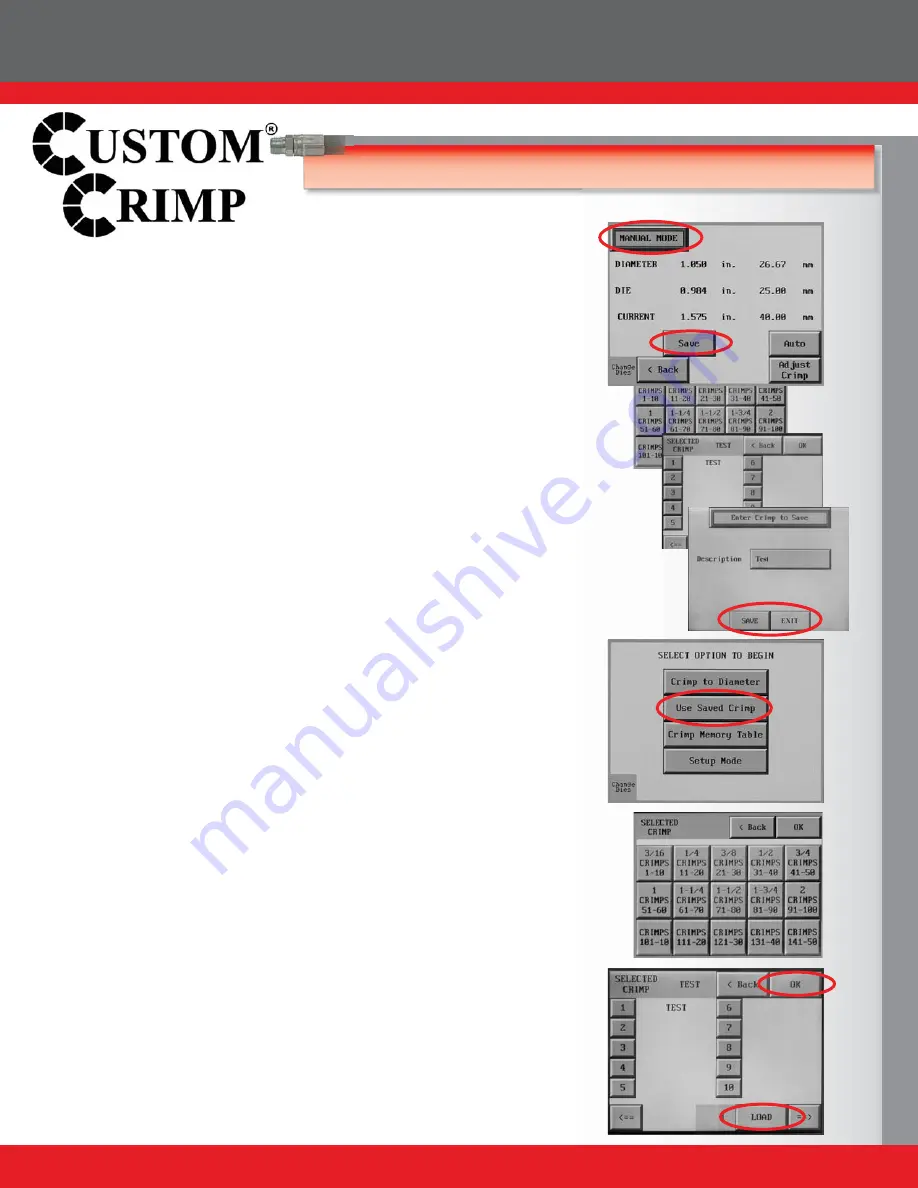

HOW TO ADD A SAVED CRIMP

•

Adjust the die diameter and crimp diameter as required and

place the crimper in

MANUAL

mode.

•

Press

SAVE.

•

Select a location (1-100) and press

EDIT.

•

Enter a description (up to 12 characters).

•

Press

SAVE

and

EXIT.

•

The die and crimp setting can now be recalled from the

saved location as required.

TO RECALL SAVED CRIMP

•

Select USE SAVED CRIMP from the option screen.

•

Select a previously saved crimp from location 1-100.

•

Press LOAD.

•

Press OK.

•

The saved crimp will appear on the manual screen.

AccuCrimp ACT

TM

CONTROL PANEL QUICK START