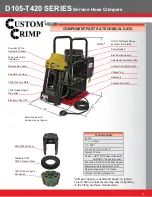

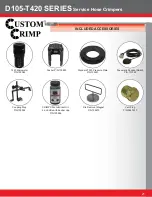

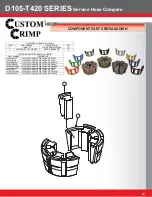

D105-T420 SERIES

Service Hose Crimpers

18

Step 4:

Slide the

Pusher

onto the pusher retaining ring on the hydraulic

cylinder.

Note:

Make sure slot in pusher goes over lip on pusher retaining ring.

Refer to page 12 for details if needed.

CAUTION:

Damage to pusher and retaining ring can occur if misaligned.

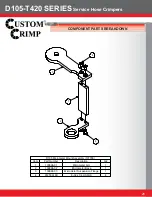

Step 5:

Set the

T420 Micro-Crimp Adjuster

at “0”.

Step 6:

Depress and hold the Start/Stop switch, until the Die set is

completely closed and oil pressure has built up in the hydraulic cylinder.

If the ram extends, the dies are completely closed, the pump builds

pressure (The sound of the pump will change) when the micrometer

touched the electronic red button as shown, “count one mississippi” the

automatic stop switch will shut the pump off, and the ram will return to

the retracted position the crimper is correctly calibrated.

CALIBRATION CHECK PROCEDURE