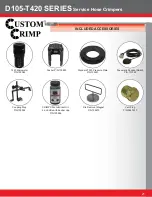

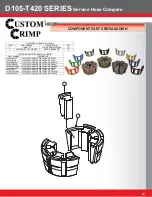

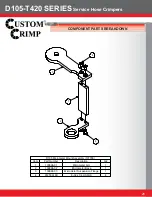

D105-T420 SERIES

Service Hose Crimpers

27

CustomCrimp® “No-Nonsense” Warranty Statement

All CustomCrimp® Products are warranted to be free of defects in workmanship and materials for one

year from the date of installation. This warranty ends when the product becomes unusable for reasons

other than defects in workmanship or material.

Any CustomCrimp® Product proven to be defective in workmanship or material will be repaired or replaced

at no charge. To obtain benefi ts of this warranty, fi rst, contact Warranty Repair Department at Custom

Machining Services at

(219) 462-6128

and then deliver via prepaid transportation the complete hydraulic

product to:

ATTN: WARRANTY REPAIR DEPT.

Custom Machining Services, Inc.

318 North Co. Rd 400 East

Valparaiso IN 46383

If any product or part manufactured by CustomCrimp® is found to be defective by CustomCrimp®, at its

option, CustomCrimp® will either repair or replace the defective part or product and return via ground

transportation, freight prepaid.

CustomCrimp® will not cover any incoming or outgoing freight charges for machines sold outside

The United States.

This warranty does not cover any product or part which is worn out, abused, altered, used for a purpose

other than for which it was intended, or used in a manner which was inconsistent with any instructions

regarding its use.

Electric motors are separately warranted by their manufacturer under the conditions stated in their separate

warranty.