HB1030E Manual Revision: 7 Page 11 of 28

Pre-start Inspection

Before use each day or at the beginning of each shift, the machine shall be given a visual inspection and

functional test. Repairs (if any) must be made prior to operating the machine, as it is critical to ensure safe

operation of the machine. A checklist for pre-start inspection can be found in the Maintenance section of this

manual.

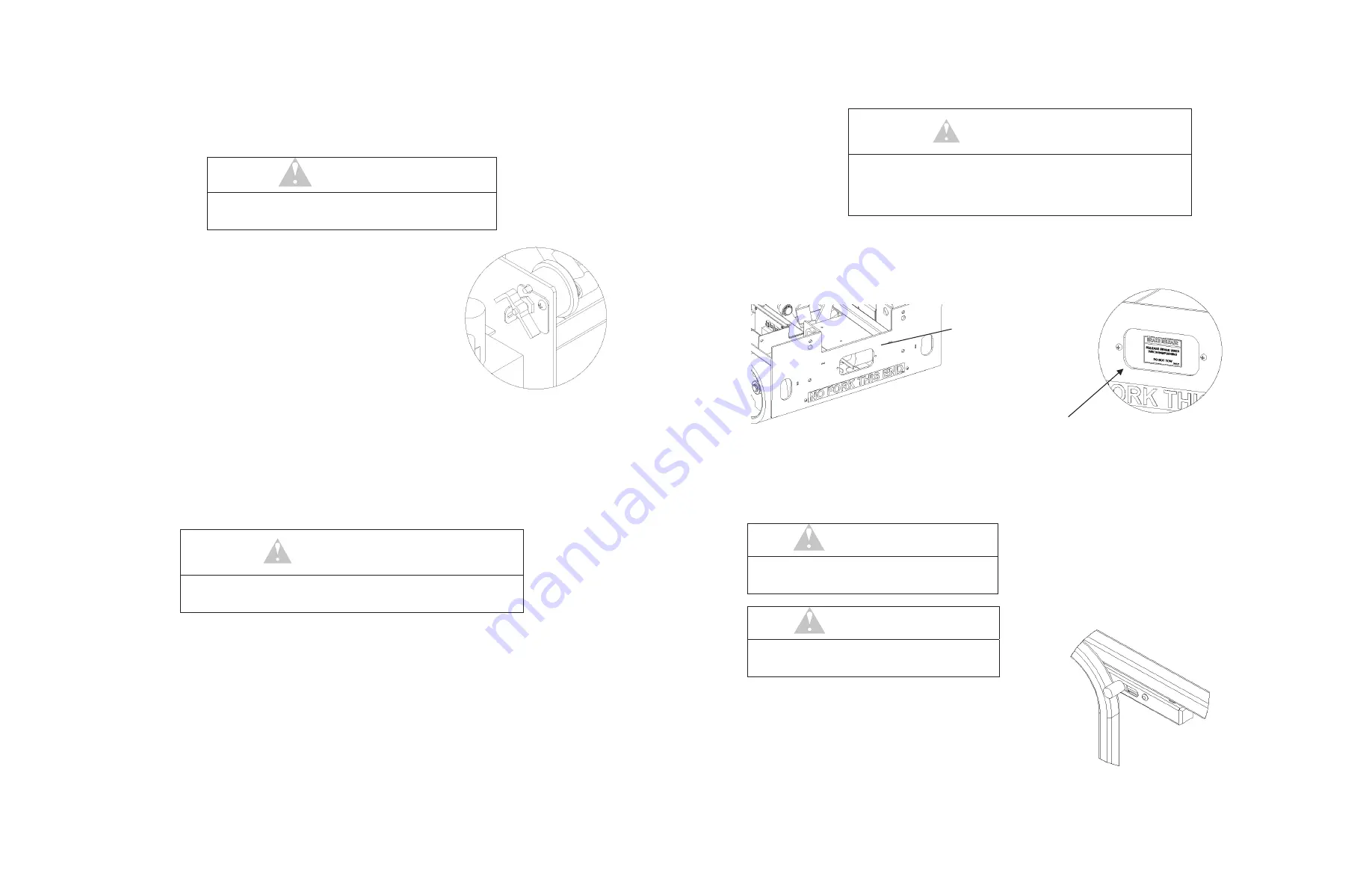

DANGER

THE OPERATOR MUST BE AWARE OF THE

ENVIRONMENT. DO NOT RAISE THE PLATFORM IF

THE MACHINE IS NOT ON A FIRM, LEVEL SURFACE.

Start Procedure

x

Check that the work area is safe.

x

Check that battery switch is in “ON” position.

x

To operate, ensure that the key in the lower control panel is in the

"ON" position.

x

An audible alarm sounds when the machine is tilted. Machine must

be on a hard, level, surface before operation.

x

Enter the work platform in the stowed position using a constant three

point dismount/grip.

x

Follow all general rules and precautions stated in this manual.

Shutdown Procedure

x

When finished with the machine, place the platform in the stowed

position.

x

Park the machine on a level surface.

x

Carefully exit the platform using a constant three point dismount/grip.

x

Remove key from lower control panel to prevent unauthorized use.

Driving and Steering

WARNING

CHECK THAT THE ROUTE OF TRAVEL TO BE TAKEN IS CLEAR

OF PEOPLE, OBSTRUCTIONS, DEBRIS, HOLES, AND DROP

OFFS, AND IS CAPABLE OF SUPPORTING THE MACHINE.

Always check front steer wheel direction before driving.

To activate drive function, depress the Drive Enable Bar on the Joystick. Moving the joystick handle away from

the operator will cause FORWARD travel and pulling the joystick toward the operator will cause REVERSE travel.

Travel speed is proportional and is controlled by the joystick. The farther it is moved, the faster the speed will be.

The joystick returns to the neutral position when released.

Use the Thumb Steering Switch on the end of the Joystick to steer left and right. Pressing the switch to the left

causes the wheels to turn left, to the right, wheels turn right. The steer switch returns to neutral position when

released. Steer wheels do not center themselves after a turn; they must be returned to the straight-ahead

position with the steer switch.

Press the horn button on the upper controls for an audible warning.

Battery Disconnect Switch:

“On” position

HB1030E Manual Revision: 7 Page 12 of 28

Braking

WARNING

PUSHING THE EMERGENCY STOP BUTTON WILL APPLY

BRAKES IMMEDIATELY. THIS MAY CAUSE UNEXPECTED

PLATFORM MOVEMENT AS THE MACHINE COMES TO A

SUDDEN STOP. BRACE YOURSELF AND SECURE OBJECTS ON

THE PLATFORM DURING OPERATION OF THE MACHINE.

For parking, the brake is automatically applied when the forward/reverse drive controller is positioned in the

center (neutral) position. In the event of a machine failure, the machine can be pushed by releasing the parking

brake at the rear of the machine.

NOTE: The drive system will not function if the parking brake is in the release position.

Extending the Slide-Out Deck

x

Stand on the platform deck.

x

Grip the Slide Lock Handle to allow the deck to

slide.

x

Slide the deck out up to 76 cm.

x

Release the Handle to keep deck in place.

WARNING

DO NOT EXCEED THE RATED CAPACITY. THE

CAPACITY OF THE SLIDE OUT DECK ID

MAXIMUM 250 LBS. OR ONE PERSON.

WARNING

IF THE SLIDE-OUT DECK IS EXTENDED,

CHECK FOR CLEARANCE UNDER AREA

BEFORE LOWERING PLATFORM.

The brake release is

behind a cover that

requires the use of a

screwdriver to remove.

Figure 13: Brake Release Cover

Figure 12: Brake Release

To release brake for

winching or pushing,

rotate brake handles.

Do not push at speeds

more than 2 mph (0.9

m/s).

Figure 14: Slide-Out Lock