1.2 | GENERAL RULES AND PRECAUTIONS

MAINTENANCE INFORMATION IS FOR USE

BY TRAINED PERSONNEL ONLY.

NEVER REACH BETWEEN SCISSORS

LINKS OR PROP UP PLATFORM UNLESS

MAINTENANCE PINS ARE IN PLACE.

SECTION 1 | SAFETY

FAILURE TO FOLLOW THIS WARNING WILL CAUSE

DEATH OR PERSONAL INJURY.

“DANGER” indicates an imminently hazardous situation,

which, if not avoided, will result in death or serious

injury.

FAILURE TO FOLLOW THIS WARNING MAY CAUSE

DEATH OR PERSONAL INJURY.

“WARNING” indicates a potentially hazardous situation,

which, if not avoided, could result in death or serious

injury

FAILURE TO FOLLOW THIS WARNING MAY CAUSE

INJURY OR DAMAGE TO EQUIPMENT.

“CAUTION” indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury or damage to equipment

CAUTION

DANGER

WARNING

An operator of any type of work platform is subject to certain hazards that cannot be protected by mechanical

means. It is therefore essential that operators be competent, careful, physically and mentally fit and thoroughly

trained in safe operation of this machine.

Although Custom Equipment, LLC conforms to specified EN: 280, it is the responsibility of the owner to instruct

operators with the safety requirements made not only by Custom Equipment, LLC, but by the various safety boards

in your area, as well as additional requirements set forth by EN: 280. If you come across a situation that you think

might be unsafe, stop the platform and request further information from qualified sources before proceeding.

1.1 | SAFETY SYMBOLS

MAINTENANCE & TROUBLESHOOTING

HB-P4.5/HB-P5.0

SUPO-648

REV G

6

SECTION 1 | SAFETY

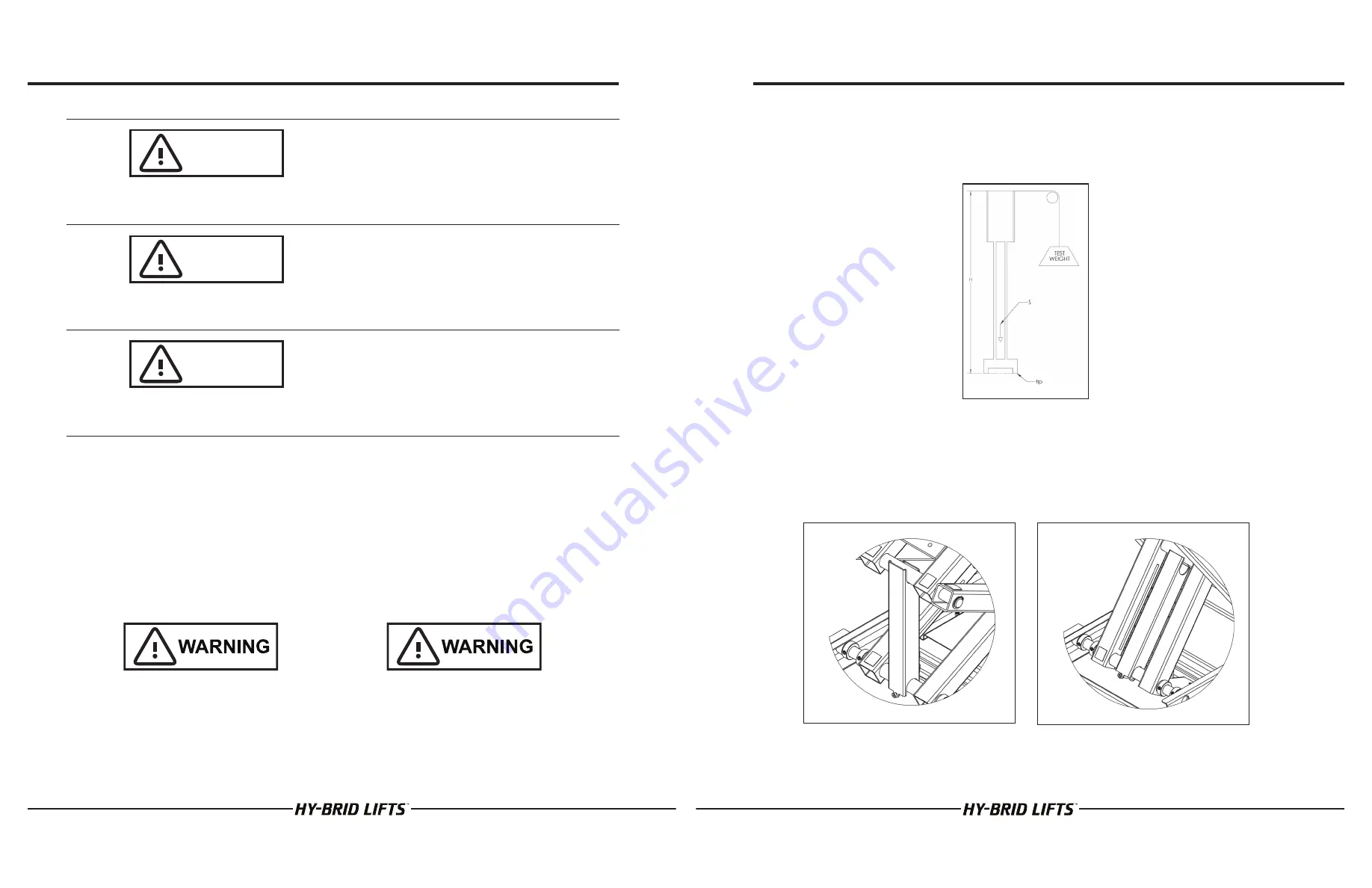

1.3 | STABILITY TESTING

The HB-P4.5 and HB-P5.0 have been stability tested to standards EN280 or AS 14180. The most adverse stability test

is the stationary, lateral slope configuration for both units. The overturning moment created by the test loads and

forces is equivalent to a test on an unloaded machine on a level surface, as shown in the figure below. For the HB-

P4.5 and the HB-P5.0, the test weight/pull force is 22.8 kg / 50 lb.

1.4 | SAFETY GUIDELINES

Maintenance Lock

The maintenance lock must be placed into position whenever the machine is being serviced in the raised or partially

raised position. Serious injury and/or death could result if maintenance lock is not used properly.

FIGURE 1: Equivalent Stability Test

FIGURE 2: Maintenance PIN Lock Use

FIGURE 3: Maintenance PIN Lock Storage

MAINTENANCE & TROUBLESHOOTING

HB-P4.5/HB-P5.0

SUPO-648

REV G

7