4

Safety Warnings Specific for Sanding Operations

Do not use excessively oversized sanding disc paper. Follow manufacturer’s recommendations when selecting sanding paper.

Larger sanding paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the

disc or kickback.

Safety Warnings Specific for Polishing Operations

Do not allow any loose portion of the polishing bonnet or its attachment strings to spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning attachment strings can entangle your fingers or snag on the work piece

Vibration safety

This tool vibrates during use. Repeated or long-term

exposure to vibration may cause temporary or permanent

physical injury, particularly to the hands, arms and

shoulders. To reduce the risk of vibration-related injury:

1. Anyone using vibrating tools regularly or for an extended

period should first be examined by a doctor and then

have regular medical check-ups to ensure medical

problems are not being caused or worsened from use.

Pregnant women or people who have impaired blood

circulation to the hand, past hand injuries, nervous

system disorders, diabetes, or Raynaud’s Disease

should not use this tool. If you feel any medical or

physical symptoms related to vibration (such as tingling,

numbness, and white or blue fingers), seek medical

advice as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood

supply to the hands and fingers, increasing the risk of

vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on

the user.

4. Use tools with the lowest vibration when there is a

choice between different processes.

5. Include vibration-free periods each day of work.

6. Grip tool as lightly as possible (while still keeping safe

control of it). Let the tool do the work.

7. To reduce vibration, maintain the tool as explained in

this manual. If any abnormal vibration occurs, stop use

immediately.

Polishing Instructions

TO PREVENT SERIOUS INJURY: Grip the tool firmly in both hands.

1. Wash the work surface thoroughly, and make sure it is

free of dust, dirt, oil, grease, etc.

2. Place a clean Foam Pad (sold separately) securely onto

the Backing Pad.

3. Apply about two tablespoons of wax (not included)

evenly on the clean Foam Pad.

NOTICE:

Do not apply the wax directly to the surface of the

vehicle. The amount of wax needed will vary according to

the size of the vehicle being waxed.

NOTICE:

4. Make sure that the Switch is in the off-position, then plug

in the tool.

Only use slower speeds for polishing. Otherwise,

damage may occur to the paint being polished. We are not

responsible for damage to the vehicle’s finish due to

improper use of this tool.

WARNING!

To prevent electric shock, keep electrical

connections off ground.

CAUTION!

5. To start, position the unit on the area to be polished, grip

the tool firmly with both hands and press the Trigger.

Release the Trigger to stop.

Start and stop the tool only while it is held firmly

against the surface of the vehicle. Failure to do so may

result in the Foam Pad or Polishing Bonnet being thrown

from the Polishing Pad.

6. Keep pressure off of the tool when operating. The Foam

Pad should LIGHTLY contact the polishing surface.

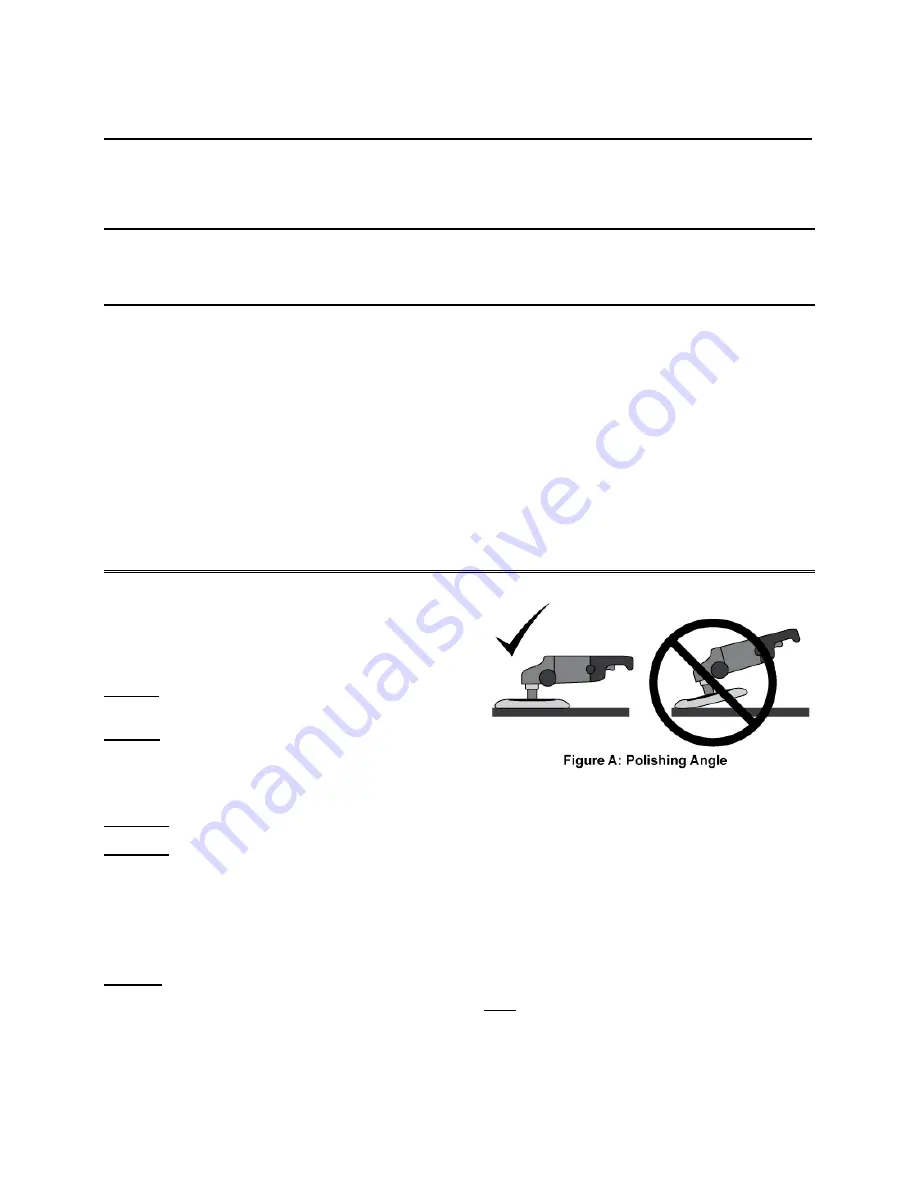

NOTICE:

To prevent damage to the foam pad, polishing

bonnet, and vehicle finish: Only apply the pad/bonnet flat

against the surface, see below.

7. Begin using the tool to apply wax to the vehicle. Apply

the wax to all flat surfaces with broad, sweeping strokes

in a crisscross pattern. Apply the wax evenly over the

surface of the vehicle.

8. Add additional wax to the Polishing Pad as needed. To

add additional wax:

a

.

Stop the tool and allow the tool to come to a

complete stop.

b

.

Add a small amount of wax evenly over the pad

surface.

c

.

Avoid using too much wax. For additional

applications of wax to Foam Pad, reduce the amount of

wax. The Foam Pad will not absorb as much wax in

subsequent applications.

d

.

Resume operation.

Note:

The most common error when waxing/polishing a

vehicle is applying too much wax. If the Foam Pad becomes

saturated with wax, applying wax will be more difficult and