REQUIRED READING

REQUIRED READING

REQUIRED READING

REQUIRED READING

REQUIRED READING...

...

...

...

...

UNDERSTAND THIS MANUAL!

UNDERSTAND THIS MANUAL!

UNDERSTAND THIS MANUAL!

UNDERSTAND THIS MANUAL!

UNDERSTAND THIS MANUAL!

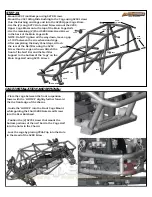

Thank You and Congratulations on purchasing the OUTLAW

OUTLAW

OUTLAW

OUTLAW

OUTLAW! Within this kit you will find a race

winning car with over 21 years worth of CUSTOM WORKS

CUSTOM WORKS

CUSTOM WORKS

CUSTOM WORKS

CUSTOM WORKS design and quality. In order for you to

realize this race car’s winning potential it is important to follow the written text along with the

pictures included. The steps required to build this car are very easy, as long as you read before you

build.

The instructional format for building this car is to open each bag in alphabetical order. Each bag of

parts will be broken down into “Steps” thru the manual. All parts and hardware needed to complete

all steps for each separate bag, will be found in each individual bag. There is no need to steal screws

from other bags. In the rare event you need to look in a different bag for a certain part, it will be

noted clearly in the instructions.

Considering the various dirt or clay surfaces that Dirt Oval cars are raced on today, the Outlaw has

been designed to be competitive on either loose packed dirt with buggy tires or high bite clay with

rubber or foam racing tires. The instructions will build the kit using the most verastale set-up Custom

Works has found in testing on different types of tracks, however there are various other suspension

configurations available to you that you may find more suitable for your local track. For updates and

more proven set-ups login to CustomWorksRC.com.

All hardware (screws, washers, nuts, etc…) are referred to by size and type in the instructions. To

help clarify which screw or nut the instruction is calling for refer to the HARDWARE REFERENCE

supplement. The size of the screw or nut should match the “shadow” of the same piece very closely.

Screw ID’s are: FH

FH

FH

FH

FH=Flat Head BH

BH

BH

BH

BH=Button Head SH

SH

SH

SH

SH=Socket Head SS

SS

SS

SS

SS=Set Screw

BUILDING TIPS:

BUILDING TIPS:

BUILDING TIPS:

BUILDING TIPS:

BUILDING TIPS:

-Using some type of thread locking fluid is suggested for all parts where metal screws thread into other

metal parts. We suggest using a lite setting strength thread lock for the reason you may want to take

the screw out one day. Remember it only takes a very small amount to secure the screw.

-Do NOT

NOT

NOT

NOT

NOT use power screwdrivers to drive screws into parts. The fast rotation speed can easily melt and

strip plastic parts or cross-thread into the aluminum parts.

-Lightly sand the edges of graphite pieces using a medium grade sandpaper to avoid splinters. Run a

thin bead of Super Glue around the edges to give pieces greater durability.

SUGGESTED TOOLS

SUGGESTED TOOLS

SUGGESTED TOOLS

SUGGESTED TOOLS

SUGGESTED TOOLS

400 Grit Sandpaper

Wire Cutters

Blue Loctite

Hobby Scissors

X-Acto Knife

3/16" Wrench

Small Needle Nose Pliers

Phillips Head Screw Driver

Summary of Contents for Outlaw 0720

Page 1: ......