24

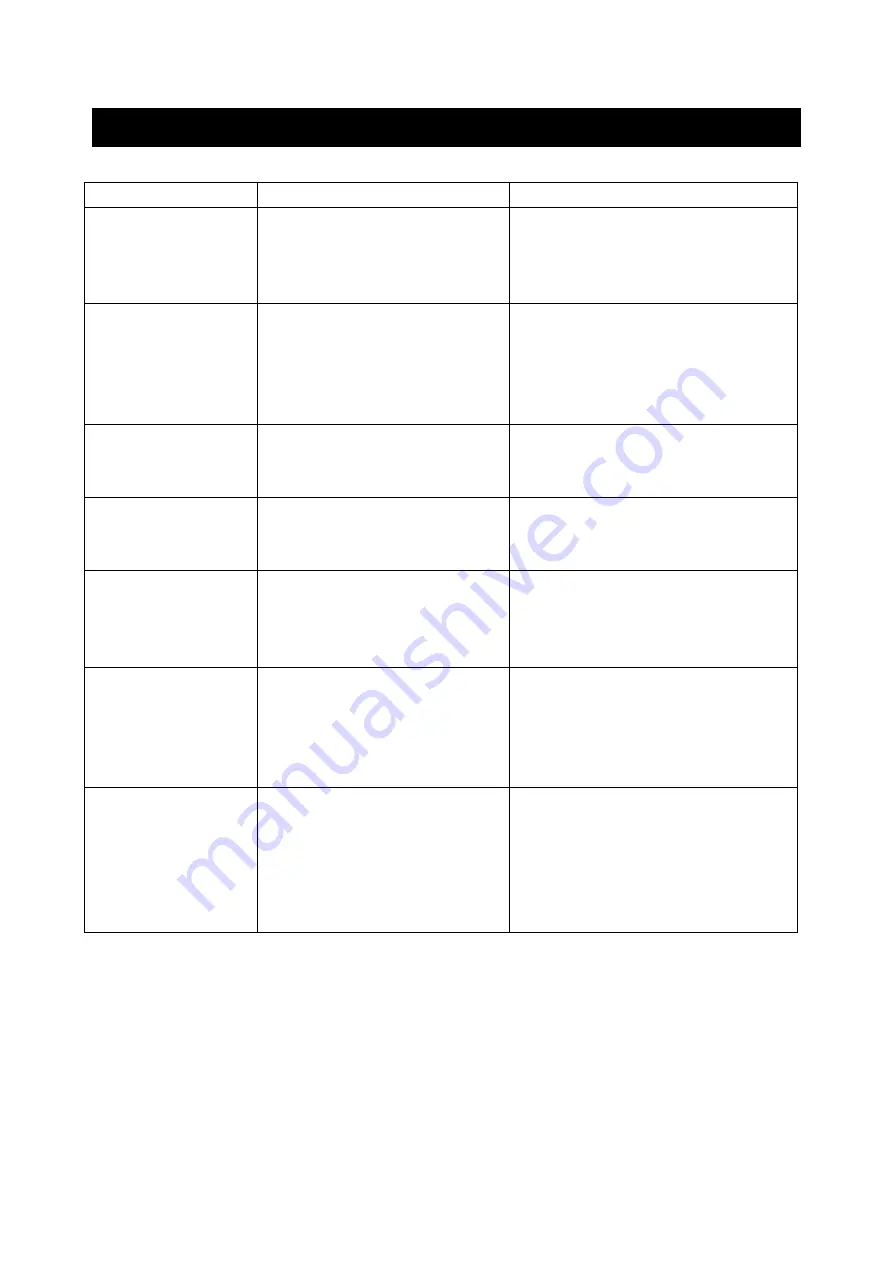

TROUBLESHOOTING GUIDE

Motor and Machine Operation

PROBLEM

LIIKELY CAUSE

SOLUTION

Snipe

(depressions at

end of work piece)

Dull Blades

Infeed or outfeed tables out of

adjustment.

Residue on rollers.

Replace or turn blades. Readjust

tables. Feed scrap of same thickness

before and after work piece.

Clean rollers.

Torn grain.

Too deep or shallow blade

setting.

Work piece being fed against

grain.

Dull cutter blades

Reduce or increase the depth of cut.

Feed other end of board first.

Replace or turn blades.

Try skewing board when feeding.

VERY slightly dampen work piece.

Fuzzy/rough grain.

High wood moisture content.

Dull blades

Too deep a blade setting.

Dry wood before planing.

Replace or turn blades

Reduce depth of cut

Board thickness

does not match

depth scale indicator.

Depth scale incorrectly set.

Adjust depth scale.

Will not start.

Not plugged in.

Blown circuit.

Lockout key removed.

Check the power source.

Replace fuse, reset breaker, or call

electrician.

Replace lockout key.

Interrupted operation

Unit overloaded.

Circuit overloaded.

Reduce load.

Operate on circuit separate from

other appliances or motors or

connect to circuit with adequate amp

rating.

Planer not feeding

properly

Too much material being

removed.

Knives or tips dull.

Build up on tables.

Build up on rollers.

Reduce cut depth.

Replace knives or tips.

Clean tables and apply paste wax.

Clean rollers with a cleaner safe for

rubber surfaces.

Summary of Contents for 40200H-CT

Page 25: ...25 PARTS 97...

Page 26: ...26...