7

Do not reach across machine. Clothing can be caught by the machine resulting in

entanglement. Keep fingers and hands away from rotating chuck and saw. This

reduces the risk of entanglement and cutting injuries. Follow operating instructions to

reduce the risk of injury from electrical shock entanglement, crushing and other

causes and prevent Hole Cutter damage.

1. Confirm that the Hole Cutting Tool and work area are properly set up and that the work

area is free of bystanders and other distractions.

2. Assume a proper operating position that will allow:

• Control of the Hole Cutting Tool, including the ON/- OFF switch and the feed handle. Do not

turn the tool ON yet.

• Good balance. Be sure that you do not have to over reach.

3. Move the ON/OFF switch to the ON position. Observe the rotation of the hole saw and pilot

drill, making sure it is running straight and true. If they wobble, or any other issues are noted,

move the switch to OFF and unplug tool, fix any issues prior to using. Keep fingers, hands

and clothes away from the turning chuck to help reduce the risk of entanglement.

4. Place both hands on the hand wheel and advance the pilot drill into contact with the pipe.

Apply firm pressure, and start drilling the pilot hole. Do not force the pilot drill/hole saw. This

can overload the hole saw and the tool

motor and cause premature failure.

Once the hole saw is in contact with the pipe, continue to apply firm pressure. Depending on

the size and wall thickness of the pipe and the size of the hole being cut, the hole saw may

need to be retracted slightly at times for chip removal. If needed, the Hole Cutting Tool can be

shut off and a small amount of appropriate cutting lubricant applied to the work piece. Do not

apply lubricant while the tool is running, this increases the risk of entanglement. Take

appropriate steps to prevent the lubricant from dripping or being thrown during use. As the

hole saw moves through the pipe and as the cut is completed, there will be an interrupted cut

at times. Decrease pressure as this occurs to help prevent jamming of the hole saw.

5. Once the hole is complete, retract the hole saw from the pipe and switch OFF.

6. Reverse the mounting procedure to remove the Hole Cutting Tool from the pipe. Make sure

you have secure grip on the Hole Cutting Tool prior to loosening the chain.

7. If the pipe slug needs to be removed from the hole saw, always make sure that the

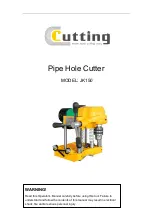

Cutting in process