37/38

S

ept

.

2014

V3.1

CybTouch 12 PS User Manual

M

SG

n

r

.

M

eSSaGe

d

eScripTion

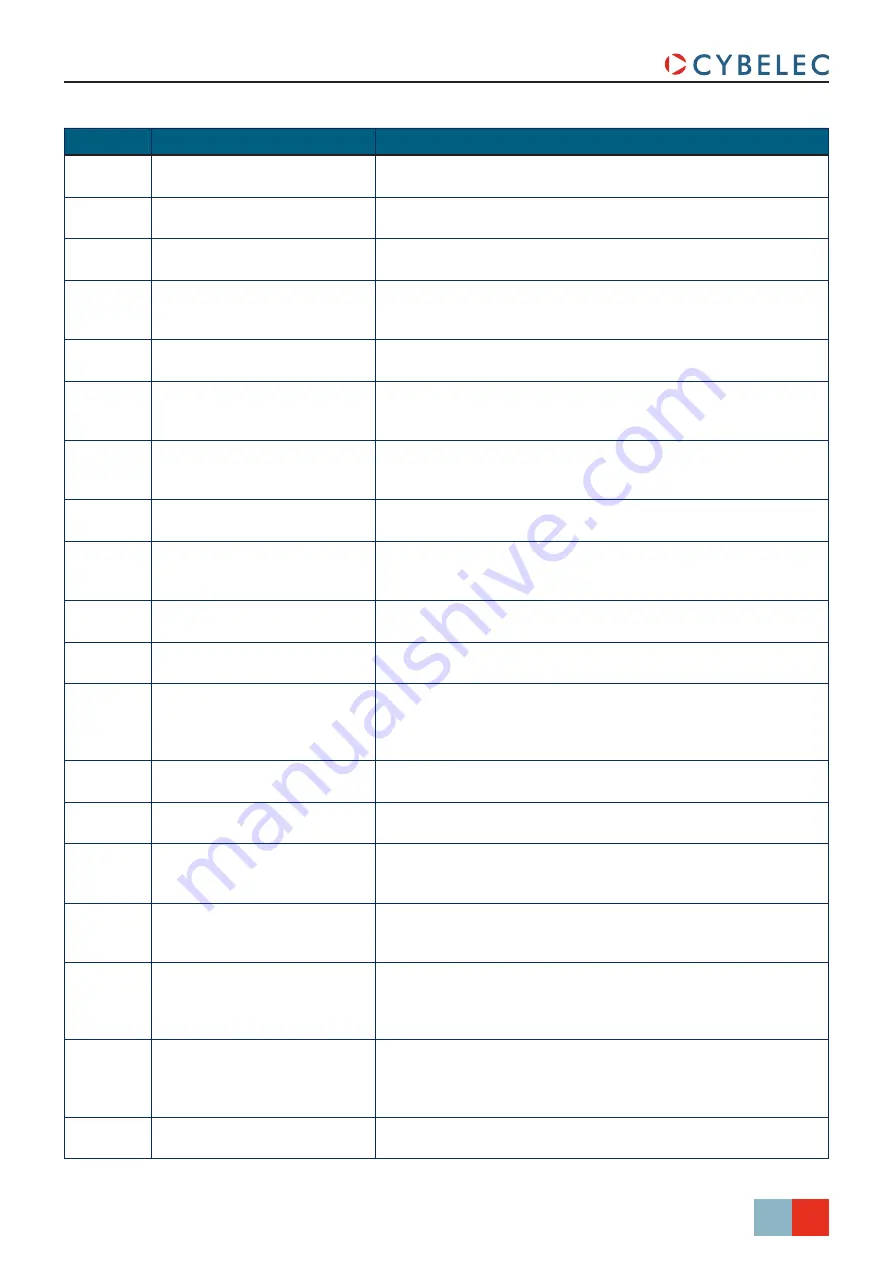

E45

Error: backgauge “rest” mode

and retract

It is not allowed to program a

with a support type of back gauge finger.

E46

“Pressure” analog output not

configured

While configuring (setting up) the NC, dedicated input or output

are not configured but are requested to run properly.

E47

R over maximum limit

The programed position value for axis R is above the value of the

maximum limit switch position.

E48

Stop doesn’t exist

This error means the operator is trying to make a bend without a

back gauge or with a back gauge whose mode is none. Select a

valid back gauge.

E50

Value out of limit

This message is displayed when the value the operator is trying

to be program is bigger than the maximum authorized value.

E51

Error[ ][ ][ ][ ]...

Internal management error. Write the error’s codes down and

the software’s number (see

Cybelec.

E52

Punch does not exist

This message is displayed when trying to create a new part

before having selected a punch in the list (see

E53

Die does not exist

This message is displayed when trying to create a new part

before having selected a die in the list (see

).

E55

Identification Error 1 (No

motion detected)

No motion detected. Should not happen if you started the Wizard

from the beginning. If the error remains, check limit switches,

drive, wiring, etc.

E56

Identification Error 2 (Not

enough oscillations)

Not enough oscillations Increase the identification time. See

machine parameters manual.

E57

Identification Error 3

(Amplitude of the oscillation)

Oscillation amplitude. Increase the identification voltage. See

machine parameters manual.

E58

Fw Axes Error 32 [Trajectory

tracking error]

This is a regulator error. The axis could not follow its trajectory.

This may be due to high friction, resistance or an obstacle on the

axis movement. This may also be a drive problem.

Call a technician.

E59

Fw Axes Error 311 [MaxSpeed

too high !]

Max speed or encoder resolution too high.

E60

Fw Axes Error 312 [MaxSpeed

too small !]

Max speed or encoder resolution too low.

E61

Fw Axes Error 313

[Acceleration too small or

MaxSpeed too high !]

Acceleration too low (mm/s

2

) or max speed too high. This needs

to be corrected. Please note that acceleration is not a ramp

distance.

E62

Fw Axes Error 314

[Acceleration too high or

MaxSpeed too small !]

Acceleration too high (mm/s

2

) or max speed too low. This needs

to be corrected.

E66

Fw Axes Error 33 [Maximum

voltage time exceeded (10V)]

This is a regulator error. The axis could not follow its trajectory.

This may be due to higher friction, resistance or an obstacle on

the axis movement. It may also be a drive problem.

Call a technician.

E67

Fw Axes Error 39 [Speed

tracking error]

This is a regulator error. The axis could not follow its trajectory.

It may be due to higher friction, resistance or an obstacle on the

axis movement. It may also be a drive problem.

Call a technician.

E68

Fw Axes Error 316 [MinPosition

or MaxPosition outside limit ! ]

Axis position counter is out of max or min limit.

Verify physical axis position and set the axis counter accordingly.