User Manual

–

Visipac & VisiTouch Series

VisiPac & VisiTouch series

–

User Manual

M

AR

.

2021

V1.0

54/69

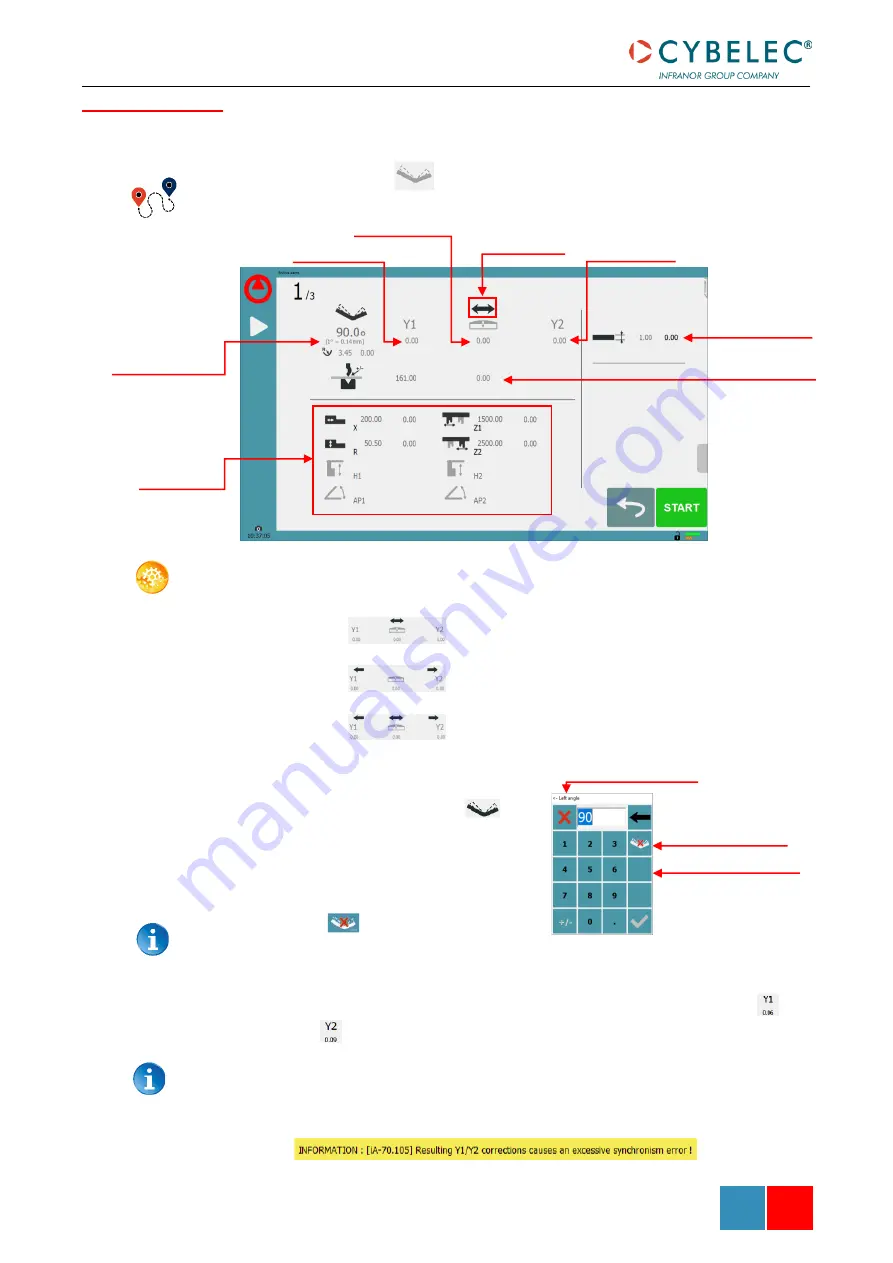

After physically measuring the angle, if corrections are to be made, they must be done on

this page, and not directly in the program step.

S

ETTING

I

NSTRUCTIONS

:

1.

Select the correction mode:

•

Equal correction in both Y1 and 2 axes

•

Specific corrections to the Y1 and Y2 axis

•

Specific correction to the Y1 axis, Crowning and Y2 axis

2.

Touch the angle correction

icon

and enter the physically measured

value of the angle. The numerical

control will automatically calculate the

Y1 and Y2 axes corrections.

Pressing this

button will reset all angle

corrections.

3.

Depending on the position of the sheet metal in the press, it may be necessary to

fine-

tune the beam’s corrections. It is possible by simply touching this icon

s

or

this

one and entering the desired values.

4.

Depending on the length part and the machine size, the corrections are calculated

in their respective ends of the machine Y1 and Y2 cylinders. It can happen that the

corrections are too important and the beam touch the limit of synchronism

between Y1 and Y2 axes, in this case a message error appear:

Angle Correction

(Y axis)

Axes correction

Reset corrections button

Pinch Point correction

Correction mode

Thickness correction

Indicative Degrees/mm

correction in function

of the selected tools

Crowning correction

Y1 axis correction

Y2 axis correction

Copy to all correction filters

Side informations

Summary of Contents for VisiPac Series

Page 1: ...VisiPac VisiTouch Series User Manual MARCH 2021 V1 0 for Synchronized Press Brakes ...

Page 6: ...User Manual VisiPac VisiTouch Series VisiPac VisiTouch Series User Manual MAR 2021 V1 0 5 69 ...

Page 64: ...User Manual VisiPac VisiTouch Series VisiPac VisiTouch Series User Manual MAR 2021 V1 0 63 69 ...