Chapter 2

:

Installation

48

SE500

CP

Hardware Manual

Verifying System Accuracy

Accuracy is the ability of the SE500

CP

to return correct measurements for known standards. The

system accuracy specification is based on the average of at least ten measurements of the

CyberOptics certification target.

●

Height Accuracy is determined by:

Accuracy (height) = Average Measured Height - Certified Feature Height

Height accuracy is reported in absolute units (e.g. mils, μm).

●

Volume Accuracy are determined by:

Accuracy (area, volume) =

(100%)

Volume accuracy is reported as a percentage of the volume of the target.

Certification Tool Kit Contents

●

SPI certification target

●

SRFF file for certification target

●

CyberOptics Certificate of Traceability

SE500

CP

Certification Target

The SPI certification target is shipped in a hardwood box that should be used for permanent

storage. Each target is engraved or marked with a serial number.

Hold the certification target by the edges as you use it, and keep it free of oils, dirt, grease, and

dust.

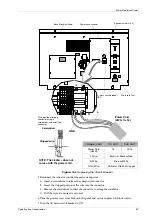

CyberOptics Certificate of Traceability

CyberOptics provides a certificate of traceability with each certification target. The certificate

includes the serial number and the certified measurements for the certification target.

Accuracy

High-Speed

High-Resolution

Height

±15 µm

(±0.59 mils)

±8.0 µm

(±0.31 mils)

Volume

±10%

±10%

AverageMeasuredHeight CertifiedFeatureHeight

–

CertifiedFeatureVolume

----------------------------------------------------------------------------------------------------------------------------------------

i

Note:

Specifications listed under “High-Speed” category are for pad size

≥

16 mils, while those

listed under “High-Resolution” category are for pads

≥

8 mils and < 16 mils.

i

Note:

To clean the certification target, use dry compressed air or a soft brush such as a lens

brush to remove debris. Make sure the surface is free of lint or dust particles. If debris is unable

to be removed by compressed air, it is recommended to use isopropyl alcohol with a lint free

swab or cloth to clean the surface.

Anything caustic (such as a metal pick or abrasive) would cause the surface profile to be

changed and hence the accuracy of the certification. If the surface is damaged or the target is

dropped, it should be re-certified.

Summary of Contents for SE500CP

Page 1: ...SE500CP Hardware Manual ...

Page 6: ...Contents vi SE500CP Hardware Manual ...

Page 10: ...x SE500CP Hardware Manual ...

Page 170: ...Index 160 SE500CP Hardware Manual ...