5

V1.0

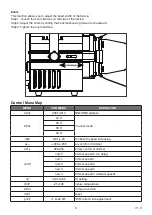

Fastening the fixture to a flat surface

The fixture can be fastened to a hard, fixed,

flat

surface that is oriented at any angle. Ensure that the

surface and all fasteners used can support at least 10 times the weight of all fixtures and equipment to

be installed on it.

Fasten the fixture securely. Do not stand it on a surface or leave it where it can be moved or fall over.

If you install the fixture in a location where it may cause injury or damage if it falls, secure it as directed

below with a securely anchored safety cable that will hold the fixture if the primary fastening method fails.

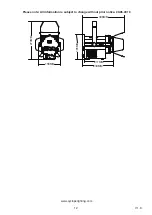

Mounting the fixture on a truss

The fixture can be clamped to a truss or similar rigging structure in any orientation. When installing the

fixture hanging vertically down, you can use an open-type clamp such as a G-clamp. When installing in

any other orientation, you must use a half-coupler clamp that completely encircles the truss chord.

To clamp the fixture to a truss:

1.

Check that the rigging structure can support at least 10 times the weight of all fixtures and equipment

to be installed on it.

2. Block access under the work area.

3. Fold the legs of the mounting bracket together and bolt a rigging clamp securely to the mounting

bracket. The bolt used must be M10, grade 8.8 steel minimum. It must pass through both mounting

bracket legs and be fastened with a self-locking nut.

4.

Working from a stable platform, hang the fixture with its clamp on the truss and fasten the clamp

securely.

5.

Secure the fixture with a safety cable as directed below.

Securing with a safety cable

Secure the fixture with a safety cable (or other secondary attachment) that is approved for the weight of

the fixture so that the safety cable will hold the fixture if a primary attachment fails.

Loop the safety cable through the eyebolt in the back of the fixture and around a secure anchoring point.

Do not loop the safety cable around the fixture’s mounting bracket only, as this will leave the fixture

unsecured if it separates from the bracket.

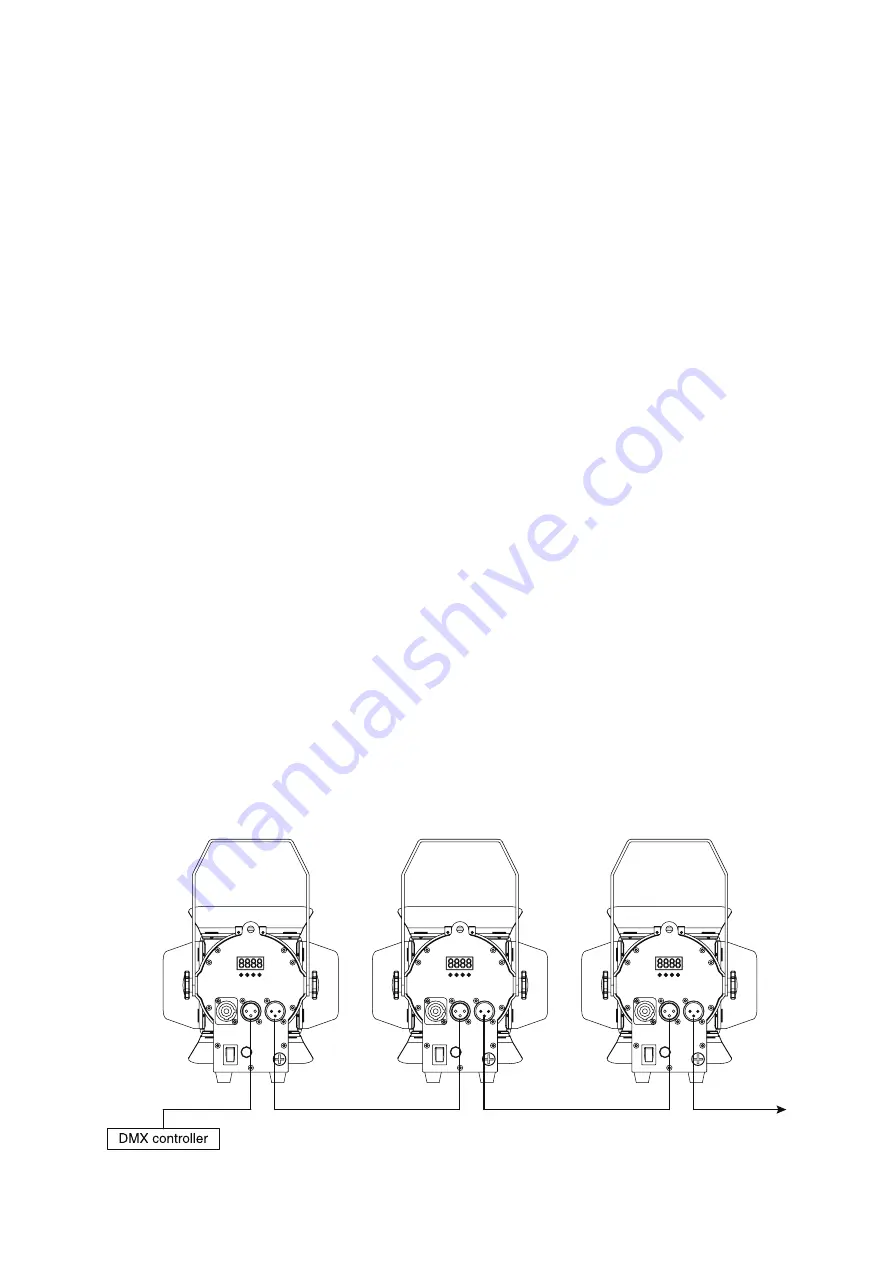

DMX-512 connection/connection between fixtures