M4-CYG1UW-TSR-M-ENG_Iss11.docx

Cygnus UW-TSR Operating Manual

9

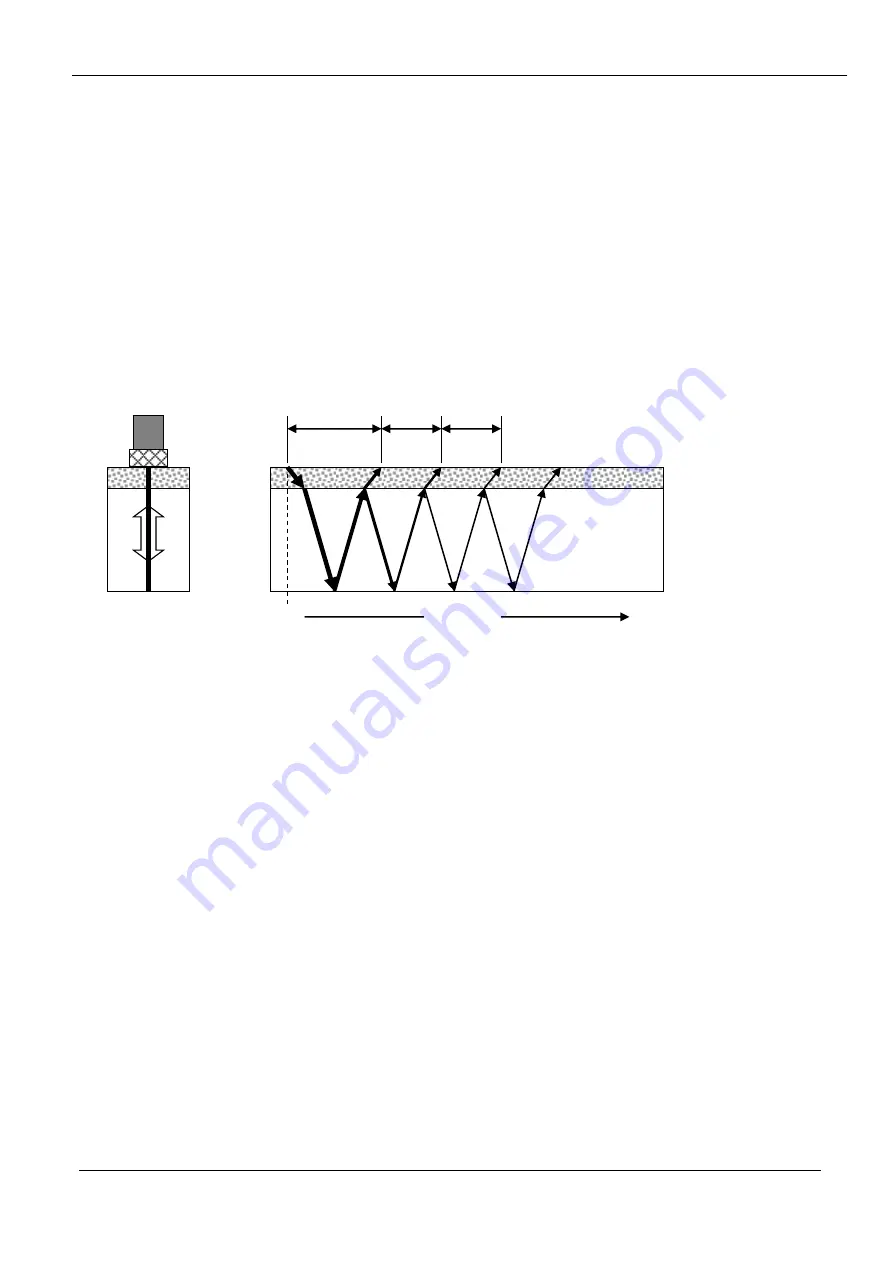

Multiple Echo Measurements

The Gauge works on the pulse-echo principle. The Probe transmits

a very short pulse of ultrasound which enters the test piece. The

Probe then acts as a receiver listening for return echoes,

converting them into electrical signals which are processed to

produce timing information that can be used to determine the

material thickness.

The

multiple-echo

beam travel is depicted above, spread out in

time, to illustrate the timing method. In reality the beam path is

straight and perpendicular to the surface as the ultrasonic energy

reverberates up and down within the metal (shown on the left).

Each time an echo is reflected back down, a small portion of the

energy comes up through the coatings (e1, e2 and e3) and is

detected by the Probe which acts as a receiver.

The delay between echoes at the Probe-face (t2 and t3) is exactly

equal to the time taken to pass through the metal twice, therefore

coatings such as paint are ignored and the measurement displayed

is the metal thickness only.

Triple Echo Verification

The Gauge requires 3 equi-spaced return echoes in order to

calculate a thickness measurement value (t2=t3). This method

ensures the Gauge only displays valid thickness values, the three

e1

e2

e3

t2

t3

Valid Thickness Measurement only when:

t2=t3

Time

Paint, Dirt etc

Metal

0

t1

Probe