6.1

User maintenance schedule

Introduction

The maintenance recommendations are different depending on the frequency of use

of your Chromaflow Packing Station. It is however recommended that trained and

certified personnel perform a preventive maintenance test procedure annually on all

instruments, pumps and valves. Contact your local Cytiva representative for more

information about available preventive maintenance agreements.

Note that the above recommendations may not apply to the specific use of your

Chromaflow Packing Station. The owner has sole responsibility for establishing appli-

cable routines for periodic maintenance.

Cleaning before planned

maintenance/service

To ensure the protection and safety of service personnel, all equipment and work areas

must be clean and free of any hazardous contaminants before a Service Engineer

starts maintenance work.

Please complete the checklist in the On Site Service Health and Safety Declaration

Form or the Health and Safety Declaration Form for Product Return or Servicing,

depending on whether the instrument is going to be serviced on site or returned for

service, respectively.

Health and safety declaration forms

Health and safety declaration forms are available for copying or printing in the Refer-

ence information chapter of this manual, or on digital media supplied with the user

documentation.

Maintenance in connection to each

run or weekly

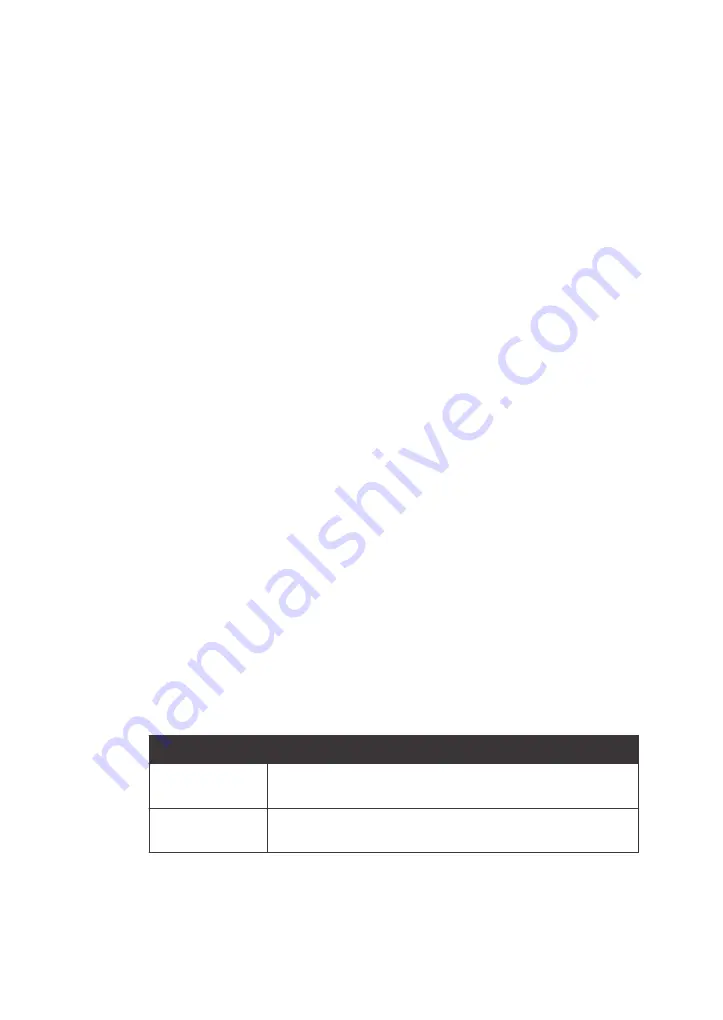

The table below describes maintenance actions required for each run or weekly

(depending on which happens first).

Component

Action

Complete system

Clean/sanitize according to the procedure described in

Section 6.2 Cleaning, on page 68

.

Protective earth

Make sure that the protective earth wiring is not disconnected

or damaged.

Monthly maintenance

The table below lists maintenance actions that are required monthly.

6 Maintenance

6.1 User maintenance schedule

66

Chromaflow Packing Station 50, 100, 200, and 400 Operating Instructions 29046228 AD

Summary of Contents for Chromaflow 100

Page 97: ...Pageintentionallyleftblank...