PS-28 Cruiser

PS-28N Cruiser

CR-MM-1-0-00

CHAPTER 10 – POWERPLANT

Revision No.: 20

Date of issue: 2017-12-05

10 - 40

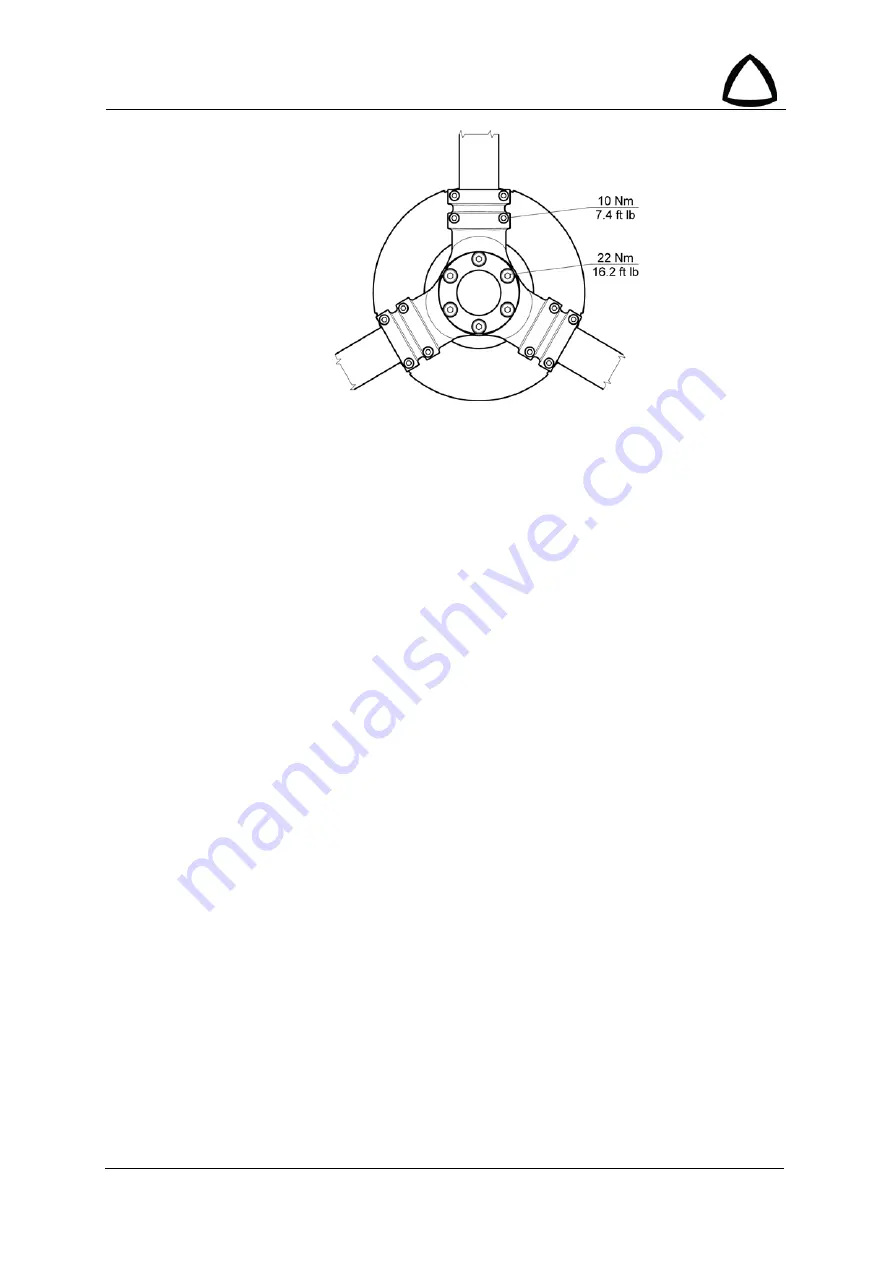

Fig. 10-21

: Torque moments

(g) Secure fixing bolt heads by lock wire (see 15.8.2).

(h) Install the propeller spinner.

Inspection of propeller after 100 hours of operation or 12 months

(a) Remove the propeller spinner.

(b) Cut off the lock wire securing the fixing bolt heads.

(c) Check the propeller blades pitch setting and correct if needed, see 10.4.2.3.

(d) Tighten the fixing bolts (Fig. 10-21) M8 by moment 22 Nm (16.2 ft.lb.)

(e) Tighten the bolts M6 on spokes of the hub by moment 10 Nm (7.4 ft.lb.).

(f) Inspect firm seating of all blades, - blades must not show any signs of movement or play in

the hub.

(g) Visually inspect the blades for damage due to a direct strike (rock, bolt, etc.) or traces of

damage or deformation. As a damage, it is not mentioned the usual operational wear (by

friction, operation, washing, etc). Relevant findings of failures must not be of a higher extent

than stated in the Operator’s manual UM-07, see the latest issue on the Woodcomp

websites. The small failures stated in the Operators manual can be repaired by the Certifying

staff (EU1321/2014), see 2.5.1 for details.

(h) If the inspection doesn’t bring satisfactory results, stop using the propeller immediately and

have the propeller inspected/repaired by authorized service organization or by the

manufacturer.

(i) If the inspection is without findings, secure fixing bolt heads by lock wire (see 15.8.2).

(j) Install the propeller spinner.

Inspection of propeller after 500 hours of operation or 36 months

Remove the propeller and send to the manufacturer or his authorized organization

Inspection of propeller on 1,000 hours of operation or 72 months

Remove the propeller and send to the manufacturer or his authorized organization