CR-MM-1-0-00

PS-28 Cruiser

PS-28N Cruiser

CHAPTER 15 – AIRPLANE REPAIRS

Date of issue: 2011-03-08

Revision No.: -

15 - 17

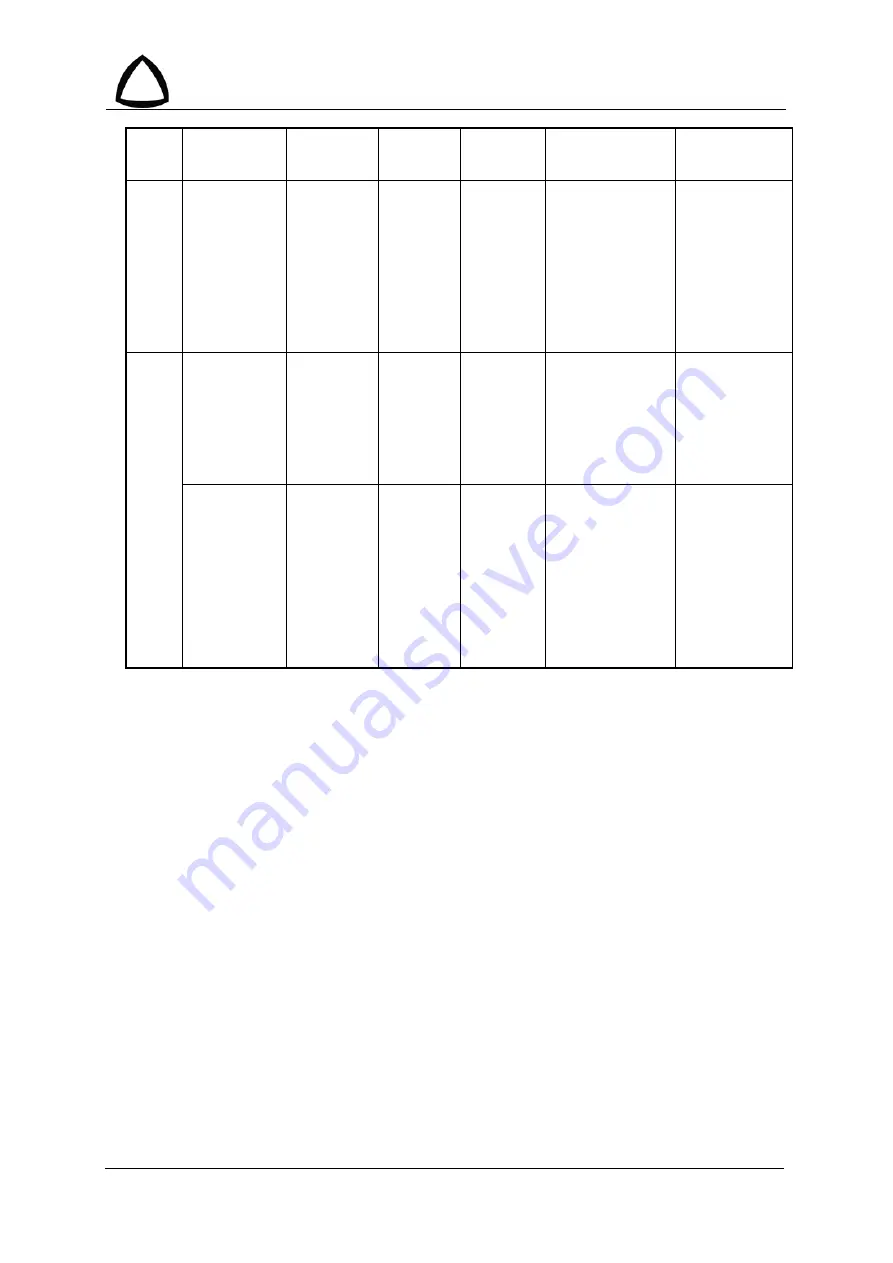

Color

type

Manufacturer,

name

Type

Other

items

Surface

mass

Recomm.

thickness

Drying (between

spraying / total)

18°C (65°F)

Single

coat

BASF Glasurit

R-68 / shade

(base)

acrylic –

polyurethane

BASF

Glasurit

922-36

(standard

hardener)

Glasurit

352-91

(standard

thinner)

1-1.6

[kg/mm/m

2

]

5.24-8.38

[

lb/inch/ft

2

]

(by shade)

0.02-0.04 mm

(

0.00078-0.00157”

)

15 min / 16 hrs

Double

coat

base color

coat: BASF

Glasurit

R-55 / shade

(base)

acrylic –

polyurethane

BASF

Glasurit

352-216

(thinner,

long)

1.2-1.4

[kg/mm/m

2

]

6.29-7.33

[

lb/inch/ft

2

]

(by shade)

0.015-0.02 mm

(

0.00059-0.00078”

)

10 min / 20 min

Top coat,

bright:

BASF Glasurit

923-155 (base)

acrylic –

polyurethane

BASF

Glasurit

929-93

(standard

hardener)

Glasurit

352-91

(standard

thinner)

0.9

[kg/mm/m

2

]

4.82

[

lb/inch/ft

2

]

0.03-0.04 mm

(

0.00118-0.00157

”)

5 min / 5 hrs

Tab. 15-6

: Recommended paints

15.6.3

Small damage

15.6.3.1

General

Small damage is a deterioration of corrosion resistance. At repair the situation is made more

difficult by the fact that the substrate for repair coats is not a compact surface of basic

material but mostly al coats of surface protection (after sanding), of which not al are suitable

for (in ageing stage) for good adhesion of paint coats. Therefore we recommend to carry

out such repairs by a verified system.

Before repairing it is necessary to differentiate the type of the existing topcoat, single coat

and two-coat (with the top coat). For repair it is necessary to follow the used type of color.

It is suitable to choose the delimited area (e.g. connection of sheets, wing edge) for the

scope of the place, which is being repaired transition, is then better blended. In the case

that it is not possible to choose the area in this way, it is necessary to take into consideration

the higher difficulty of the procedure as for the uniformity of shade and elaboration of coat

transition.