CR-MM-1-0-00

PS-28 Cruiser

PS-28N Cruiser

CHAPTER 10 – POWERPLANT

Date of issue: 2020-11-19

Revision No.: 24

10 - 39

(j) Shut engine down.

NOTE:

On switching off the engine switch off ignition and withdraw the ignition key.

(k) Inspect rotary seal for leakage.

NOTE:

Due to the design of rotary seal, a certain amount of leakage is tolerated. If

the leakage is in excess of the limit rotary seal must be renewed.

Tolerated leakage:

For this check the engine must be operated until all temperatures have stabilized for a

period of 5 minutes. At that point shut down engine and ensure the ignition is switched off

and engine secured against unintentional operation. Coolant must not drip through leakage

bore, located at the base of the ignition housing, for a period of 1 minute after the engine

has been stopped.

In case this leakage test cannot be passed, the rotary seal must be renewed.

10.4.2 Klassic 170/3/R propeller – inspections, repairs, works

10.4.2.1 Summary of propeller periodical inspection

(see also 2.3.2. for details)

•

Inspection of propeller after the first 25 hours of operation.

•

Inspection of propeller after 100 hours of operation or 12 months *,

•

Inspection of propeller after 500 hours of operation or 36 months *,

•

Inspection of propeller after 1000 hours of operation or 72 months *,

*) hours of operation or months, whichever comes first.

NOTE:

Inspection/overhaul of propeller must also be performed in the following cases:

-

The propeller has contacted the ground and/or foreign object,

-

The propeller has been overspeed (see max operating RPM in User’s Manual),

-

The propeller has been damaged

-

The propeller has no record of operating hours and/or calendar months.

10.4.2.2 Prescribed inspection works

NOTE:

Inspection of propeller after the first 25 and after 100 hours of operation may

be performed by aircraft engineer or certifying staff, see 2.5.1.

Medium repair / overhaul after 500 and after 1000 hours of operation may be

performed by manufacturer or his authorized service organization only.

All works / operations must be performed in accordance with the respective maintenance

manuals, contact the manufacturer or authorized service organization for details.

Inspection of propeller after the first 25 hours of operation

(see also the Operator’s manual

UM-07 or relevant instructions on the Woodcomp websites for details)

(a) Remove the propeller spinner.

(b) Visually check of propeller surface – propeller must not have apparent damages, breakings

and deformations.

(c) Check the propeller blades pitch setting and correct if needed, see 10.4.2.3.

(d) Cut off the lock wire securing the fixing bolt heads.

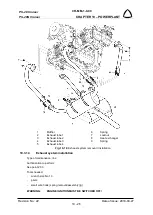

(e) Tighten the fixing bolts (Fig. 10-21) M8 by moment 22 Nm (16.2 ft.lb.). Tighten also the fixing

bolts of spacer In case it is used.

(f) Tighten the bolts M6 on spokes of the hub by moment 10 Nm (7

.4 ft.lb.

).