CR-MM-1-0-00

PS-28 Cruiser

PS-28N Cruiser

CHAPTER 10 – POWERPLANT

Date of issue: 2017-12-05

Revision No.: 20

10 - 45

10.5.2 Exchange / Refilling cooling liquid

Refer to the Rotax Maintenance Manual – Cooling System.

NOTE:

Recommended types of coolant are shown in the Rotax Operator's Manual,

Section 2.3 Coolant, Rotax Installation Manual - Cooling System, Rotax

Service Instructions SI-912-016

Type of coolant used by aircraft manufacturer is shown in section 17.5 Operating liquids.

Cooling liquid volume

Total volume of coolant in the engine is approximately 2.6 litres (

0.69 US gallons

) *.

*) Total volume of coolant for airplanes equipped with dual circuit thermostatic valve is

approximately 2.9 litres (

0.77 US gallons

) - valid for airplane S/N C0547, all airplanes since

S/N C0589 or all other airplanes which have been later equipped with dual circuit thermostatic

valve.

Drainage of cooling liquid

Disconnect the hose supplying liquid from the radiator to the pump (at the lowest point of the

system) and drain cooling liquid into the prepared vessel.

Refilling cooling liquid

Refill cooling liquid into the expansion tank in the engine compartment. In addition to this there

is a overflow bottle which collects cooling liquid in case of engine overheating and is attached to

the fire wall.

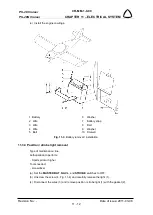

10.5.3 Exchange / Check of oil filter

Refer to the Rotax Maintenance Manual, Chapter 12-00-00, Section 5 Oil System

NOTE:

Carry out at every oil exchange.

WARNING:

RISK OF SCALDS AND BURNS!

Always allow the engine to cool down to ambient temperature before starting work.

Proceed with this work only in non-smoking area and not close to sparks or open flames.

Switch off ignition and secure engine against unintentional operation. Secure aircraft against

unauthorized operation.

(a) Disconnect negative terminal of aircraft battery.

(b) Remove the oil filter.

(c) Remove the filter insert, cut of the upper and the lower lid of the insert. Remove the middle

part of the insert, disassemble and check for metal chips, foreign corpuscles and

contamination.

CAUTION:

IF YOU DETECT AN INCREASED QUANTITY OF METAL PARTICLES

(BRASS OR BRONZE CHIPS OR BEARING ABRASIVE), FIND OUT THE

REASON AND ELIMINATE IT.

(d) Install the new oil filter. Slightly lubricate the sealing ring of the new filter with engine oil

and tighten it up manually by a normal force.

(e) Restore the aircraft to original operating configuration