JF-1A Conductivity Sensor

A440-009

Page 13 of 56

FEBRUARY 2009

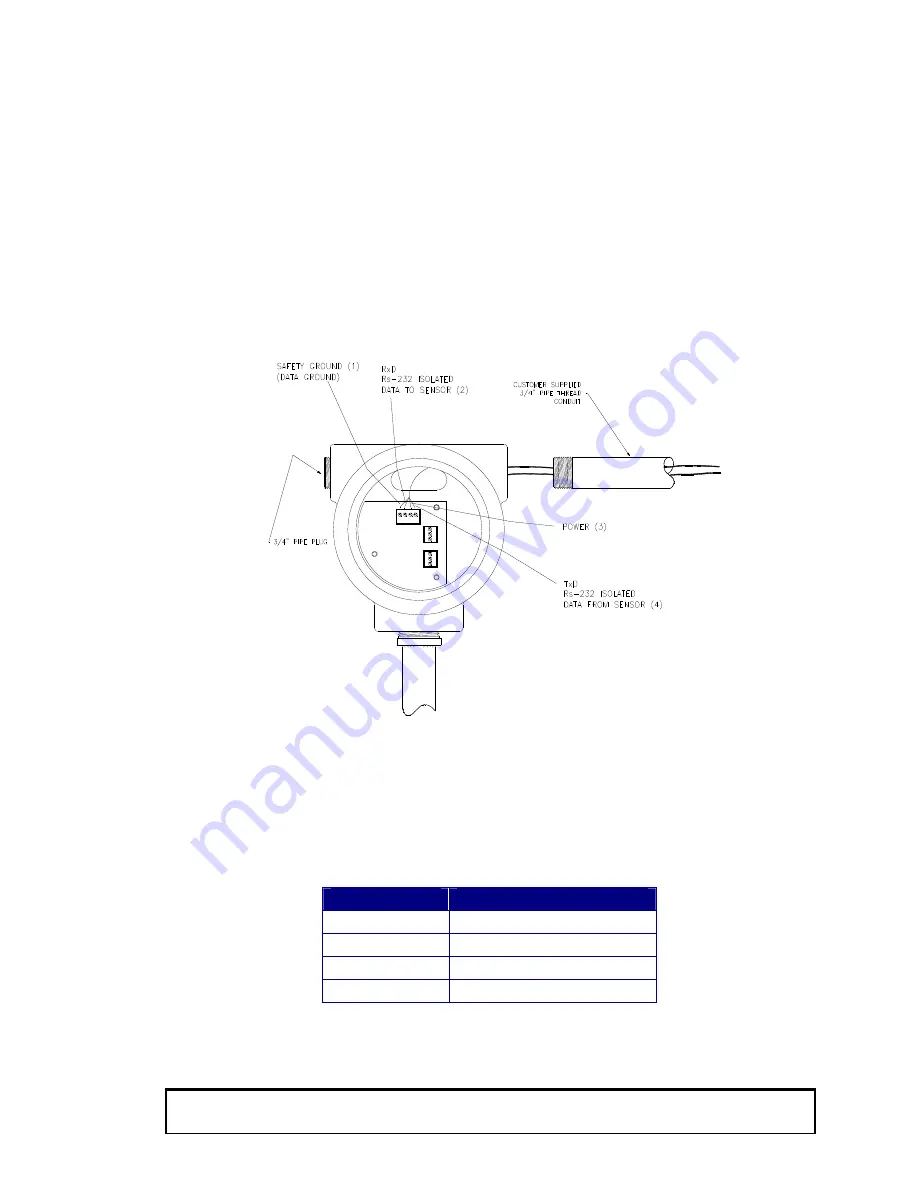

7.3 RS-232 CONNECTIONS Considerations (4-Wire)

Figure 8A

4-WIRE ELECTRICAL CONNECTION DETAIL

1 2

4

3

3

2

1

3

2

1

The 4 Terminal Screw Connector has both Power Input and RS-232/RS-485

Connections as listed in Table 1 below:

TABLE 1

SCREW TERMINAL CONNECTION PIN DETAIL

TERMINAL

Function

1

Data/Power Ground

2

RS-232 Data In (RXD)

3

Power Input +

4

RS-232 Data Out (TXD)