TITLE

OPERATOR MANUAL

PAGE

PRINTERS

ARTRIX H8

21

VERSION

2017SEP01/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

77

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

3

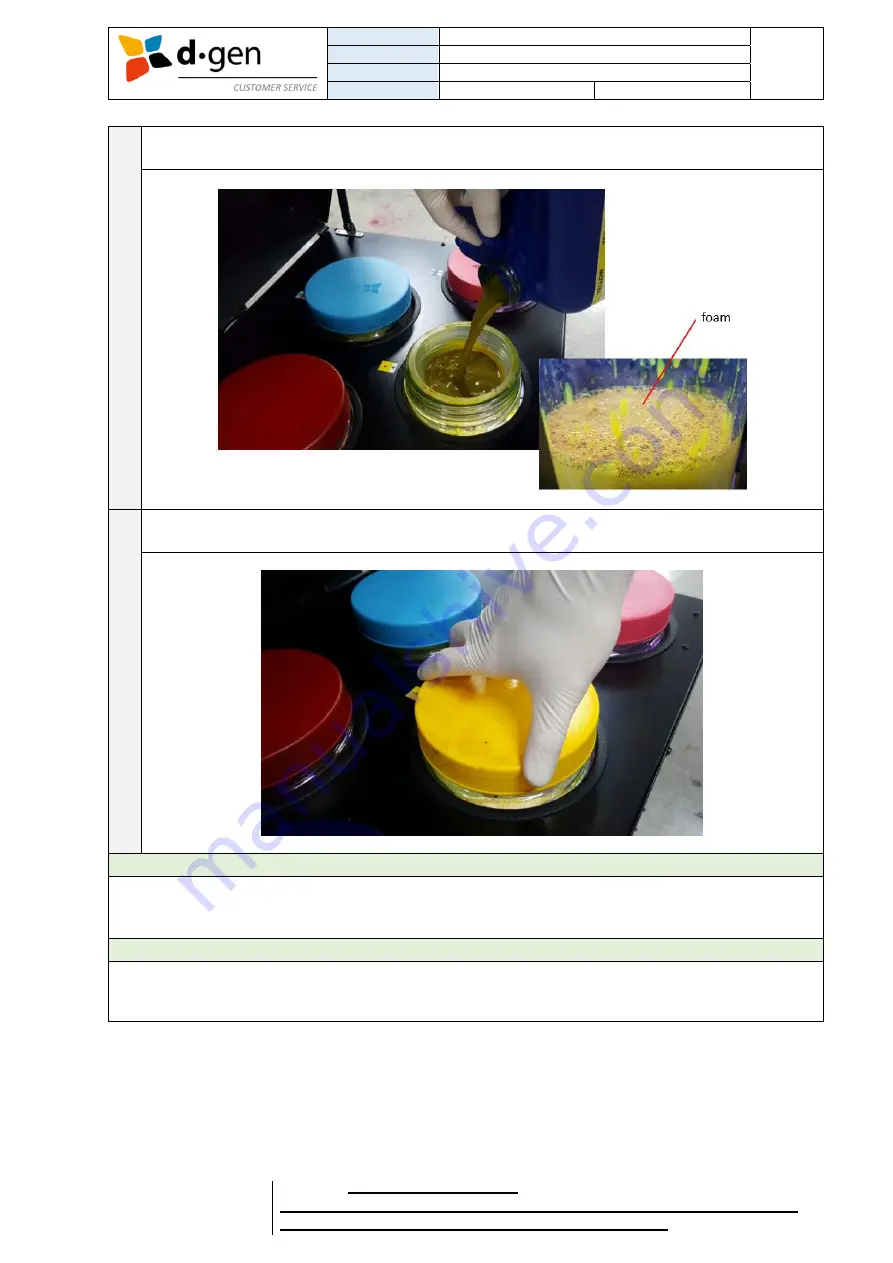

Pour gently to avoid spilling ink outside the cylinder. Do not pour the ink too fast. Leave some time

to let the ink go through the filter before pouring some more.

4

Close the lid. Do not close the lid too tight to let the air go into the cylinder as it gets empty when

printing.

Important

Do not wait until the cylinder gets completely empty. Risk of clogging the ink filter / damaging the heads

with the deposited ink sediments at the bottom. We strongly suggest to refill the tank as soon as the

buzzer is heard.

Important

When pouring ink, foam will be created. Do not let the foam get into the printer. This may negatively

affect the quality of your printings. Therefore, we suggest to refill the tank as soon as the buzzer is heard.

Summary of Contents for Artrix H8

Page 1: ...OPERATOR MANUAL ...