9/36

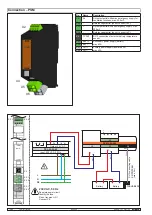

CPS-M1-MSE

4x 0,8 Ø

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

2x 0,8 Ø

2x 0,8 Ø

OK

OK

4x 0,8 Ø

English

99.828.70 1.2/07/22

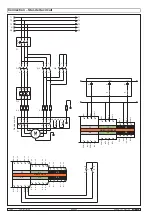

General instructions for connection

•

The connections, particularly the earth connections, may be connected to the respective associated PSM supply module and components only.

No cross-flow of current may occur.

•

System voltage 24 V DC and/or 230 V AC!

•

If 24 V DC and 230 V AC cables are laid in the same cable duct in the control panel,

it must be ensured that the

insulation of each conductor must be designed for the highest nominal voltage (≤ 250 V)

.

•

A green-yellow core may only be used as protective earth conductor.

Wiring diagram (sample)

When selecting and routing cables, regional

installation requirements pertaining to electric

cable systems and necessary safety devices,

and/or directives pertaining to maintaining the

function of electrical cables must be observed

(e.g. MLAR guidelines for the fire protection

requirements to be met by cable systems in

Germany).

Note:

Due to the variety available on the market,

no type designations are specified for these

cables. Please contact your D+H Partner for

this information.

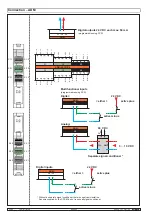

Cable line (control

panel - detector)

The cables are monitored for short circuits and

line breaks.

Cables for D+H SHEV systems

Cable group (control panel - drive)

At least three-wire design:

• 2 wires

for supplying the drive

(Mot.a/

Mot.b)

• For

pole-changing drives, 1 additional

wire

for cable monitoring, through which

the SHEV high-speed (HS) signal is also

transmitted to the drive.

• For

ACB drives, 2 additional wires

for the

bus connection.

Cross-section (mm²) = cable length (m) x total current

80

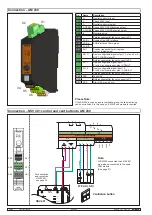

Wind/rain sensor

SHEV control panel

External control

SHEV operation panel

Approx. 1.5 m

above upper edge

of finished floor

Ventilation button

Approx. 1.2 m

above upper edge

of finished floor

Fire detector

SD-O 371 or FD-T 271

Drive on

SHEV opening

See cable lengths and cross sections

230 V AC 50 Hz

Separate power circuit.

Identify the fuse.

to additional

Total current

1 A

2 A

3 A

4 A

5 A

6 A

7 A

8 A

9 A

10 A

2 x 1,5 mm²

120

60

40

30

24

20

17

15

13

12

m

2 x 2,5 mm²

200

100

65

50

40

33

28

25

22

20

m

• max. cable length 500 m

• min. cable cross section 1.5 mm²

•

A maximum voltage drop of 6.5% (3% with

third-party drives) on the cables is permitted.

• Max. 45 drives can be connected to a group

•

The following two formulas must always be

used to calculate cable cross sections. The

higher value must be used.

Cable lengths and cross sections for Mot.a and Mot.b (AM 24 / 24 V drives)

Cable lengths and cross sections for L ▲, L▼, N and PE (AM 230 / 230 V drives)

Total power consumption

200 VA 500 VA 800 VA 1100 VA 1400 VA 1700 VA 1840 VA

5 x 1,5 mm²

167

167

167

132

104

85

79

m

5 x 2,5 mm²

278

278

278

220

173

142

131

m

5 x 4 mm²

444

444

444

351

276

227

210

m

Formula 1:

Cross section (mm²) =

Basic cable length (m) x total power of all Drives (VA)

96600

Formula 2:

Cross section (mm²) = Basic cable length (m)

111