99.830.99 1.2/11/15

9/24

CDP-TW-K-BSY+

CDP-TW-K-BSY+

English

The drive will be full configured by factory.

The drives must be reconfigured in case of

alterations (e.g. removing of drives

from existing set or integrating

a new drive) with software SCS.

If after mounting the measure x is as 23 mm or

bigger, null balance with software SCS or special

magnet MAG 502 is neccesary.

Closure Ranges will shift in relation to new zero

point.

Mount the drives mechanical stress-free.

With that, a better load distribution

is ensured on all the drives.

At vertical active pulling application

(e.g. for a skylight) the forces must

be rearranged by software SCS

Mounting informations

≥ 23 mm ?

X

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

Disposal

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder

Maik Schmees

Member of the Board

Authorized signatory, Technical Director

17.11.2015

Maintenance and cleaning

Inspection and maintenance has to be carried out

according to D+H maintenance notes. Only original

D+H spare parts may be used. Repair is to be carried

out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up

to maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing

of D+H products with parts of other manufacturers.

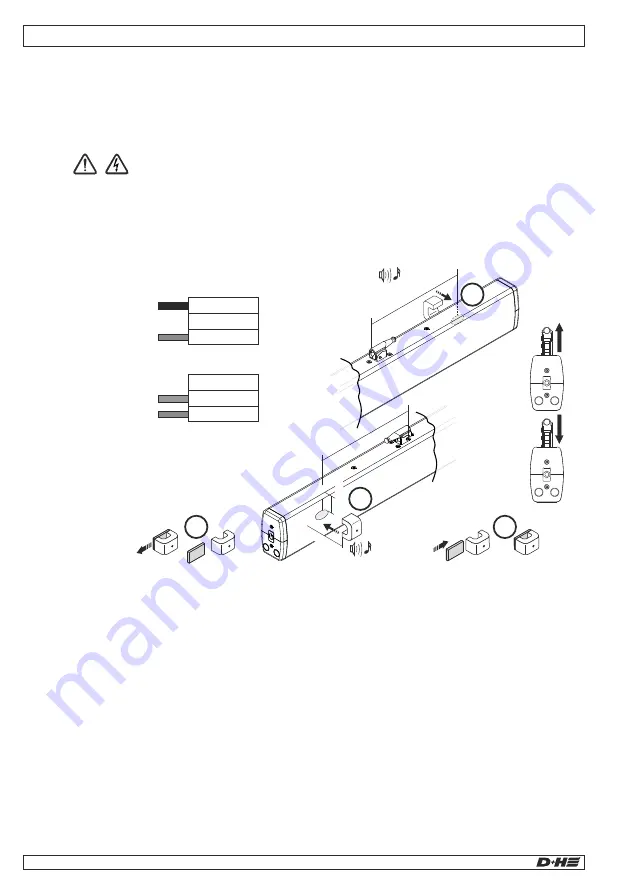

MAG 502

~287 mm

Klick... Klick

~ 20 mm

~40 mm

MAG 502

Klick... Klick

~287 mm

=

=

1

3

2

2

Emergency control / Zeroing

Emergency control

(only synchronous group)

BSY+ synchronous control regulates and monitors the difference in position between the drives (max. 30

mm). In the event of an error, all drives are stopped. Before the decision is made to run the drives in

auxiliary mode, the cabling should be checked. A short circuit, a reversed phase sequence or an

interruption of the bus line will cause the drives to stop or not start up.

When running the drives in auxiliary mode, only the drive in the synchronous group to which the magnet

is held is driven. The running direction is determined by the activation direction.

Danger!

Operating voltage 230 V AC! Risk of injury from electric shock!

Do not reverse L+N! Connect PE! The BSY+ bus also operates with 230V!

Strain on glass can cause the glass to break.

Cordon off the danger area.

Take personal safety precautions.

A second person must be able to interrupt the drive voltage at any time.

Zeroing

If repeat zeroing of a drive is necessary for installation reasons (chain is driven out > 23 mm in closed

position) or for servicing:

Travel the drive to closed position. Wait until the drive has driven completely closed.

Perform zeroing on the drive using the MAG 502 magnet. The magnet gives the drive a second CLOSE

command and performs zeroing in the event of an overload cut-off. This is confirmed by the drive quietly

humming. Each drive of the set must be individually zeroed in a synchronous group.

+

+

CLOSE –

emergency control

230 V AC

BU (N)

BN (L

s

)

230 V AC

OPEN –

emergency control

BU (N)

BK (L

r

)