99.827.73 1.0/10/18

VCD-0203-1-ACB-R

VCD-0203-1-ACB-R

6/16

7/16

99.827.73 1.0/10/18

English

English

Closing edge protection

In the "CLOSE" direction the drive has an active

protection for the main closing edge. If there is an

overload in the closing ranges C3 and C2, the drive

runs "OPEN" for 10 seconds, then "CLOSE" again. If

closing is not possible after three attempts, the drive

remains in this position.

In addition, the drive is equipped with passive

protection. The closing speed in closing range C2

and C1 is reduced to 5 mm/s.

Significantly greater forces can be

exerted at the secondary closing

edges. Danger of crushing hands and

fingers!

Main closing edge

Beside closing edge

Beside closing edge

C3*

200 N

Opening and Closing Ranges

O1*

C1*

C2*

O2*

O3*

23 mm

150 N

77 mm

150 N

23 mm

200 N

15 mm

200 N

200 N

Technical Data

* Programmable with software SCS ** + approx. 20 % switch-off reserve (temporary)

Type

VCD-0203-0250-1-ACB-R

Power supply

Nominal force

24 V DC / ± 20 %

200 N**

Nominal current

0,35 A

Nominal stroke length*

250 mm

±

2 %

Running speed:

O1, O2

O3

C3

C2, C1

6 mm/s

5 mm/s

6 mm/s

5 mm/s

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N (Excluding bracket)

>20.000 double strokes

30 % (With cycle time 10 minutes)

Zinc-diecasting powdercoated (~ RAL 9006)

IP 30

0 ... +60 °C

≤ 90 %, not condensing

LpA ≤ 46 dB(A)

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

ACB interface

Modbus RTU / RS 485, 19.200 bps, 8 data bits, 1 stop bit, parity: even

- The drive set is fully configured ex factory.The

drives must be reconfigured using the software

SCS in the event of changes to the ex-factory

configuration (e.g. when removing a drive from

existing set or integrating a new drive).

- Mount the drives whilst under zero stress. With

that, an even load distribution is provided by all

the drive chains.

- At vertical active pulling application (e.g. for a

skylight) the forces must be rearranged by

software SCS.

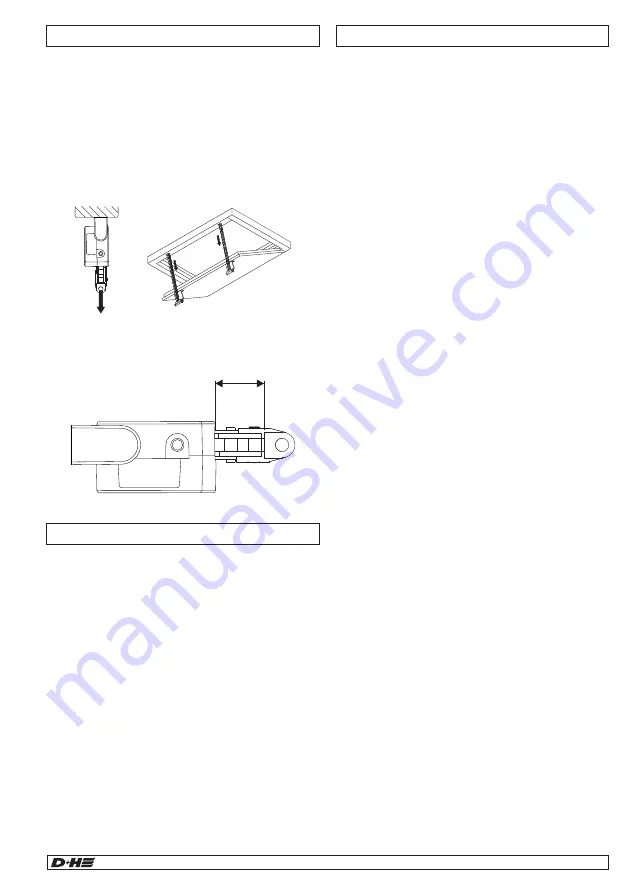

- If after mounting, the distance X is greater than 23

mm, null balance with software SCS is neccesary.

Closure Ranges will shift in relation to new zero

point.

Mounting information

ACB interface

ACB is used for secure communication between

the drive and compatible D+H control systems. It

enables activation, diagnostics and configuration

with perfect position, directly from the control

panel. In this process, all status messages, such

as the OPEN and CLOSED signals, opening

stroke and drive errors are transmitted to the

control panel.

The ACB bus is based on an open Modbus RTU

protocol via which the actuator can be directly

controlled and queried.

Further information can be found in the D+H ACB

Planning Manual.

BSY+ synchronised electronics:

A synchronous group can contain up to 8 drives,

which communicate via bus. Each drive has its

own address, configurable with SCS.

The last drive of a synchronous group is the

master, which controls the other drives, the slaves.

Differences in forces between the drives of a group

are balanced by means of intelligent force and

position control. In the event that a drive

malfunctions, all the drives are automatically cut

off.

In addition, up to 4 BSY+ lock drives and modules

can be connected.

Functional description

Visual inspection:

Only one master drive is allowed.

The master always has the last address of all the

drives; this can be found on a sticker attached to

the drive. Slaves are numbered downwards from

the master, so that in a group of three drives, for

example, the master is no. 3, with a slave 2 and

slave 1 drive. Please note that this only applies in

the ex-factory configuration. As soon as the drives

are reconfigured with SCS, the ex-factory

addressing no longer applies.

Wiring:

Is the drive or drive group wired properly?

See connection plans.

Diagnostics with SCS software:

The SCS software and a BSY+ interface is

required for further troubleshooting or

configuration.

Troubleshooting

≥ 23 mm ?

X