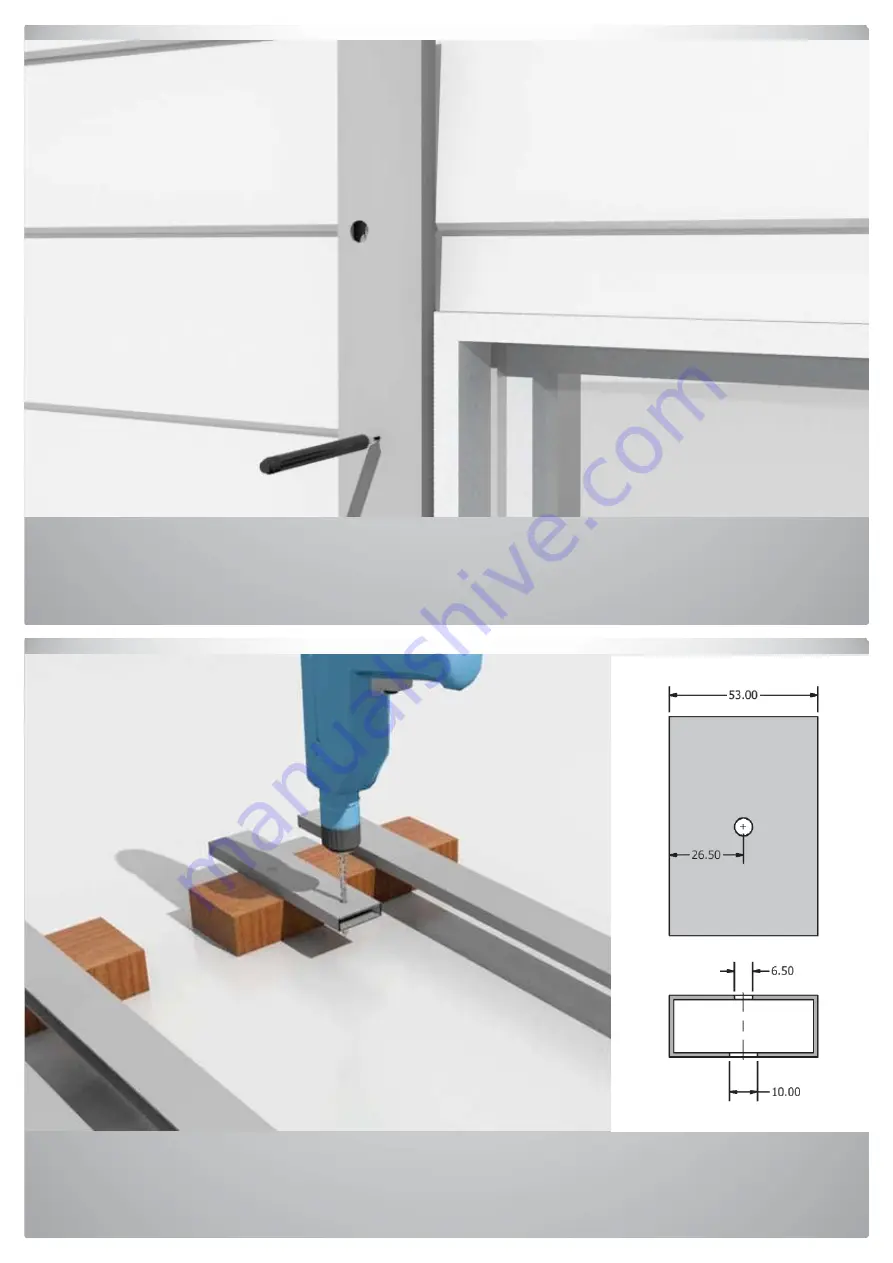

Step 5: Mark at least 3 fixing points on the packer approx. 100 mm from the top and bottom and distribute the

holes approx. 400~500 mm apart making sure you place the holes over the bullnose (the highest point on the

timber).

Step 6: Put the packer back on the ground and use the 6.5 mm drill bit to drill the holes all the way through on

the points you have marked. Do the same on the other the packer.