9

Screen Adjustment

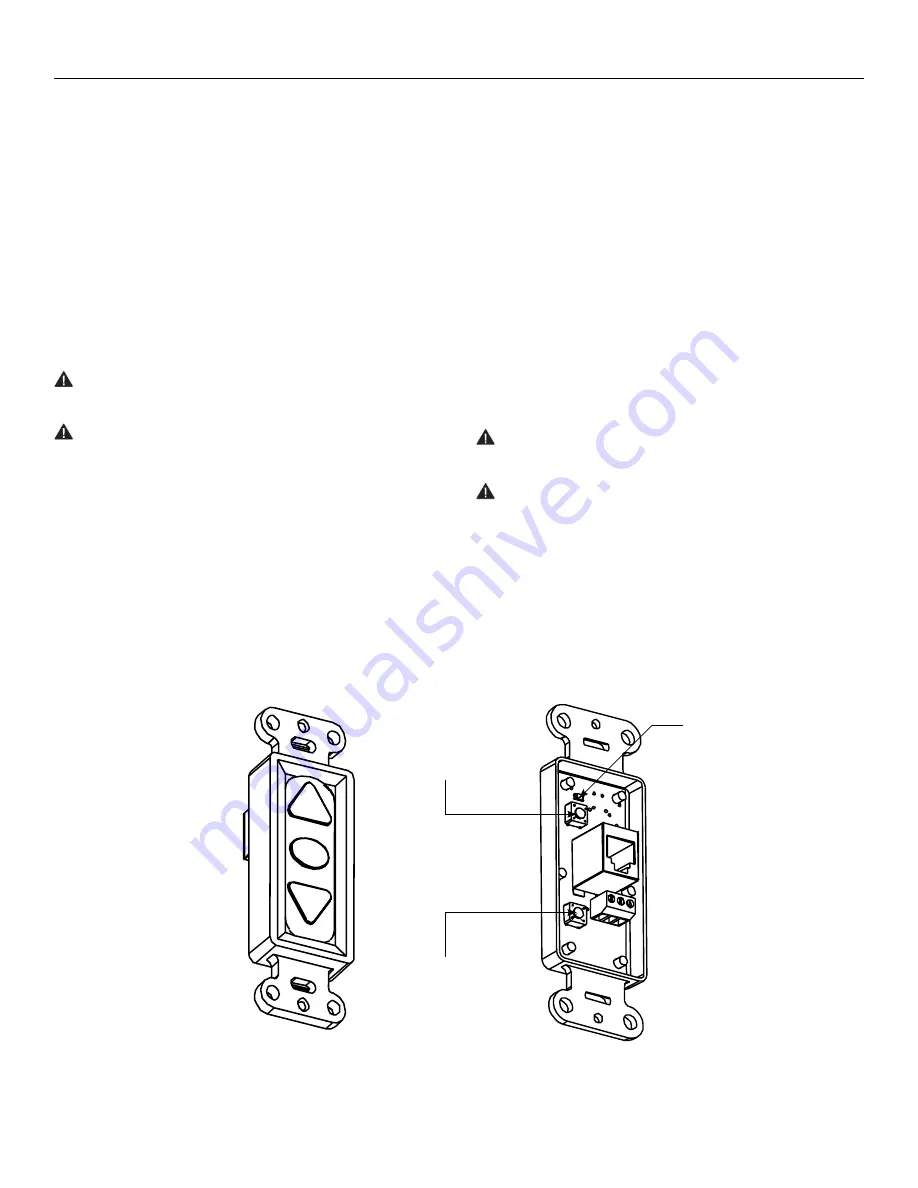

1. Locate the wall switch and remove the cover plate from the

wall switch and remove the switch from the junction box.

2. Locate the two tactile buttons on the back of the switch.

They are black round buttons on silver plates.

3. To adjust the down limit switch, press and hold the down

tactile button until the LED on the back of the switch turns

solid red. This will put the motor in limit set mode. Turn the

wall switch over and use the down button on the front of the

switch. Press and hold the down button until the desired

down position is reached. If you travel too far down, press the

up button to move the screen upward. If you press and let go

of either the up or down buttons, the motor will do a small

jog in that direction for fine adjustment of the screen. Once

the desired position is reached, turn the switch over; press

and hold the down tactile button until the LED on back of

switch blinks red twice. The down limit is now set.

CAUTION: Do not adjust for more drop than what was

ordered. At least 1–1/2 wraps of fabric must remain on

the roller.

ATTENTION! N'effectuez pas de réglage pour obtenir un

déroulement supérieur à celui commandé. Au moins 1 à

1/2 tour de toile doit être maintenu sur le cylindre.

NOTE:

If the screen is in limit set mode and no buttons are

pushed for 20 seconds, the LED on the back of the wall

switch will turn off, the motor will return to run mode and no

changes will be saved. If this occurs, return to step 3 for down

limit adjustment or step 4 for up limit adjustment.

4. To adjust the up limit switch, press and hold the up tactile

button until the LED on the back of the switch turns solid

green. This will put the motor in limit set mode. Turn the wall

switch over and use the up button on the front of the switch.

Press and hold the up button until the desired up position is

reached. If you travel too far up, press the down button to

move the screen downward. If you press and let go of either

the up or down buttons, the motor will do a small jog in that

direction for fine adjustment of the screen. Once the desired

position is reached, turn the switch over; press and hold the

up tactile button until the LED on back of switch blinks green

twice. The up limit is now set.

5. To test the limit switch settings, press and release the up or

down buttons on the switch to operate the screen.

6. Replace the switch and cover plate on the wall.

IMPORTANT NOTE:

The wall switch is REQUIRED to make

any limit switch adjustments, even if a third party control

system is used. Therefore, it is advised to wire the switch or

provide a 3-conductor connection that is accessible.

Tensioned Screens

Models with tab-tensioned surfaces are standard with 12" of black

drop at the top.

CAUTION: Adjusting the down limit switch for less drop

by more than 6" can cause the screen surface to lose

proper tensioning.

ATTENTION! LE FAIT D'AJOUTER NE DÉROULEZ PAS

TROP L'ÉCRAN PLUS DE 15 CM (6PO) AUX

INTERRUPTEURS DE FIN DE COURSE PEUT FAIRE

PERDRE LA BONNE TENSION À LA SURFACE DE L'ÉCRAN.

Non-Tensioned Screens

Non-tensioned screens are pre-set with 2" of black drop at the

top with a total of 12" of fully adjustable black drop available.

UP

STOP

DOWN

BUS

C

O

M

5

V

Front of Wall

Switch

UP

STOP

DOWN

BUS

C

O

M

5V

LED

Up Limit

Tactile Button

Down Limit

Tactile Button

Back of

Wall Switch