5

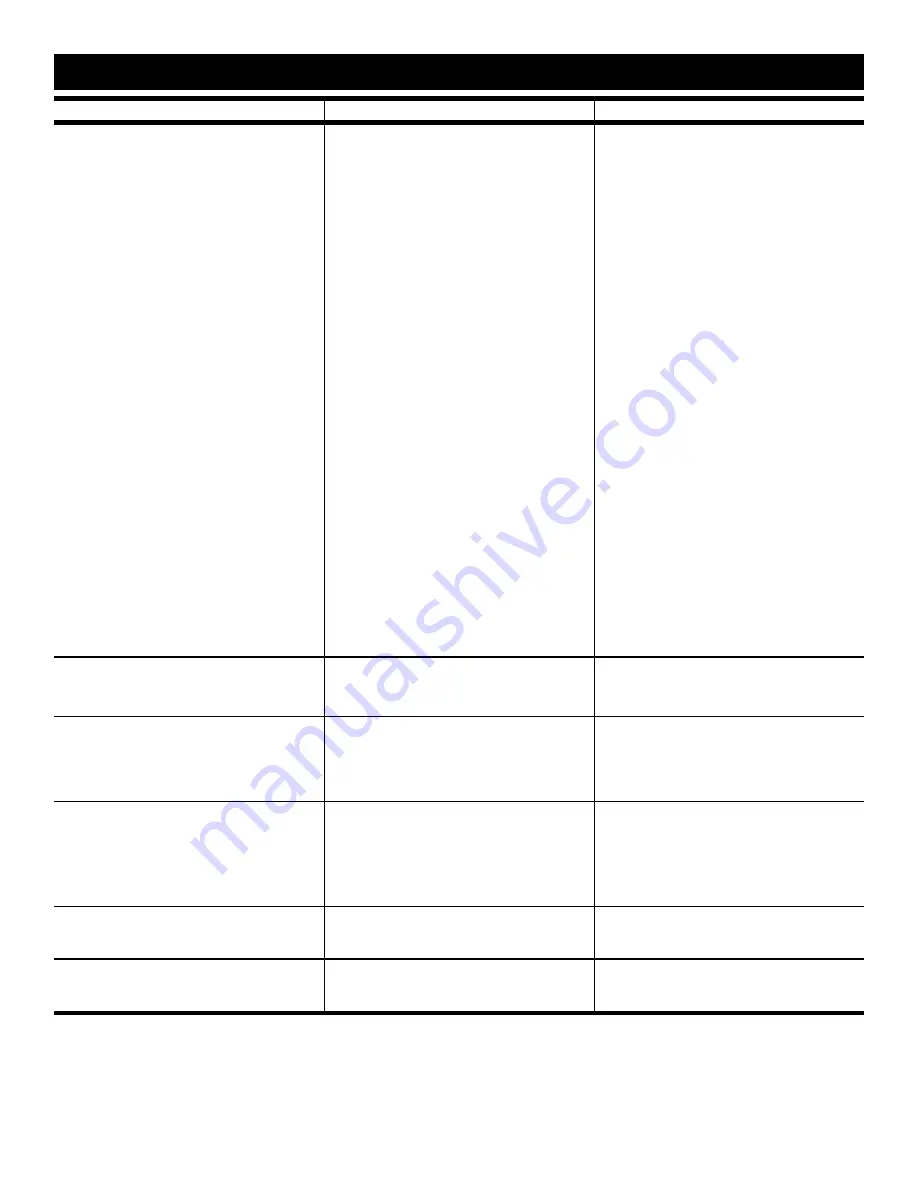

TROUBLESHOOTING

SYMPTOM

1. Screen will not operate.

Motor does

not

hum.

Motor

hums.

2.

Incorrect stopping position in

downward

direction.

3.

Incorrect stopping position in

upward

direction.

4.

Noise.

NOTE: Screen will operate with a

low pitched hum.

5.

Coasting.

6.

Roller displaced from mounting

bracket.

CAUSE

(a) Incorrect line voltage.

(b) Blown fuse.

(c) Tripped circuit breaker.

(d) No power to operating switch

or junction.

Power at junction box

(e) Thermal overload tripped.

(f) Broken wire in the

“up”

or

”down”

position.

(g) Defective motor, limit switch or

capacitor.

(h) Temporary binding.

(i) Capacitor burned out.

(a) Lost roller wrap.

(b)

“Down”

limit switch out of

adjustment

(a) Lost roller wrap.

(b)

“Up”

limit switch out of

adjustment

(a) Squeaking rubber end plug

rubbing on motor.

(b) Grinding due to foreign object in

screen rubbing on roller or fabric.

(c) Gear noise.

(a) Defective brake.

(a) Pin end slipped out of nylon bear-

ing.

RESTORING LOST ROLLER WRAP

1. Push strap over back of roller.

2. Tape end of strap to pocket.

3. Feed fabric as you pull strap to

draw fabric over top.

4. Remove tape and strap.

SOLUTION

(a) Verify 115-125V (or 220-240V). If

insufficient voltage, rewire incom-

ing electric line.

(b) Replace fuse.

(c) Reset circuit breaker.

(d) Check above. Tighten all loose

wire connections. Correct any

improper connections.

“Down” Position

Check for power across black

and white leads.

“Up” Position

Check for power across red

and white leads.

(e) Let motor cool down for 15

minutes. Try again.

(f) Check for continuity. Cut off old

splice and reconnect.

(g) Replace motor assembly.

NOTE: Motor is a sealed assembly.

(h) With power

“off”

, turn roller by

hand to free binding.

(i) Replace motor assembly.

(a) See instructions below.

(b) See installation instructions.

(a) See instructions below.

(b) Adjust

“up”

limit switch. Turn

clockwise to expose more fabric.

See installation instructions

(a) Adjust roller to center of case.

(b) Remove foreign object.

(c) Replace motor assembly.

(a) Replace motor assembly.

(a) Remove pin end mounting.

Re-align motor in tube. Re-attach

pin end.

Summary of Contents for Designer Electrol

Page 7: ...6 ...