ENGLISH

61

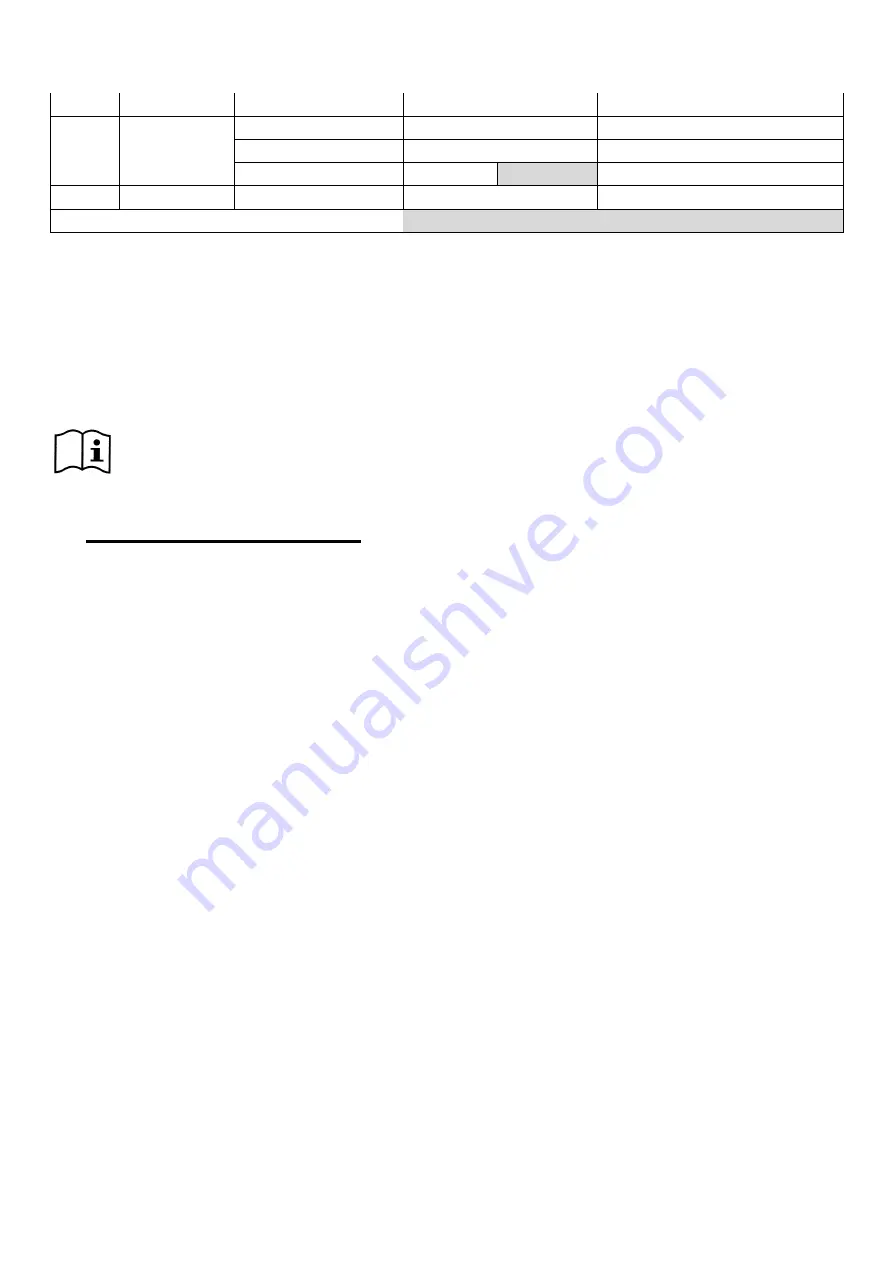

Max Priming Time

10 min

8

Anti-Freeze

function

enabled

speed

30%

temperature

4 °C

40 °F

9

Anti-Lock

function enabled

(*) Factory value on some markets

Table 6 – Factory (default) settings

8.1 Restoring the factory settings

To restore the factory values, switch off the device, wait until the display has switched off completely, press and hold

down simultaneously the two keys “

SET1

” and “

SET4

” and turn on the power; release the keys only when the

messages appear on the display.

This restores the factory settings (consisting of a message and a rereading on EEPROM of the factory settings

permanently saved in the FLASH memory and listed in the table above).

Once all the parameters have been set, the device returns to normal operation.

NOTE: this operation obviously deletes all the parameters that have previously been modified by the

operator.

Once the factory values have been restored, it will therefore be necessary to reset all the parameters

that characterise the system, as at the first installation: for the sake of convenience, the system again

proposes the WIZARD (paragraph 4.2).

9 TROUBLESHOOTING

The pump does not start (display off):

No electric power.

Check that there is voltage and that the connection to the power network is correct.

The pump is not sucking:

No water in the prefilter or clogged prefilter.

Closed valve in the pipes.

Air getting into the suction pipe.

The motor is not working:

The electric power supply or switch are turned off.

Motor electrical connections are faulty.

Impeller blocked by foreign bodies, shaft not turning.

Noisy

pump:

Air getting into the suction pipe.

Presence of foreign bodies in the pump body.

Cavitation.

Ball bearing damaged.

Low flow rate: low pressure in the filter.

Basket or impeller clogged.

Air getting into the suction pipe.

Motor turning in the opposite direction.

Low flow rate: high pressure in the filter.

Delivery pipe choked.

Inadequate section of the power supply cables.

Pump filter clogged.