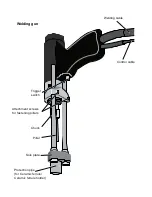

Checking

weld joints

The check is based on test weldings. The test weldings have to

be repeated carried if the values are adjusted later on. For the

simplified shop test there are two possible procedures:

•

visual inspection

•

impact bending test

Visual inspection

A purely visual inspection is only permitted if you have weld joints

which are not subject to increased pressure. As a principle it

should be done in any case.

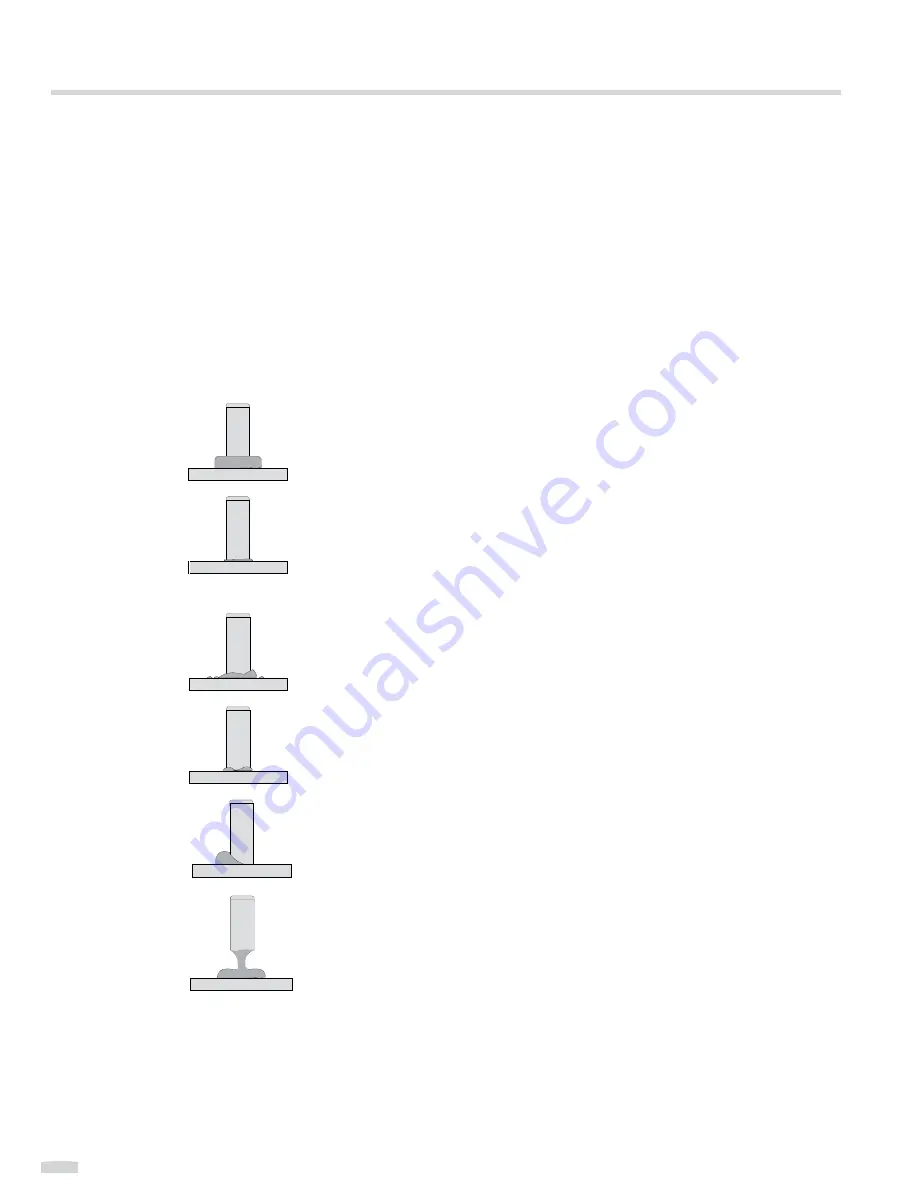

Good welding

The bead is accurate, even and closed.

With St 37 (mild steel) the surface is smooth and shining blue.

Dip measure or welding current too low, lift too smal

The bead is flat or incomplete.

The tip of the stud is only just melted on.

Welding time too long or welding current too high

The bead is flat and inaccurate. There are splashes around the

bead and on the stud.

Welding time too short or welding current too low

The bead is flat, uneven, shows hardly any visible pores and is

dull.

Blowing action

The bead is one-sided and not closed.

Stud hang-up

Heavy undercut or contraction in the welding area.

OK

Correct stud

protrusion and lift,

increase welding

time and welding

current

Correct

welding time and

welding current,

increase lift

→

Paragraph

“Avoiding magne-

tic blowing action”

Adjust sole pla-

te/ceramic ferrule,

reduce welding cur-

rent, increase stud

protrusion

Correct

welding time and

welding current

Tips for stud welding

26