12

Installation Instructions

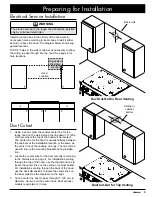

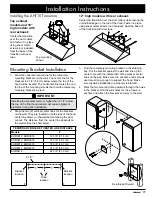

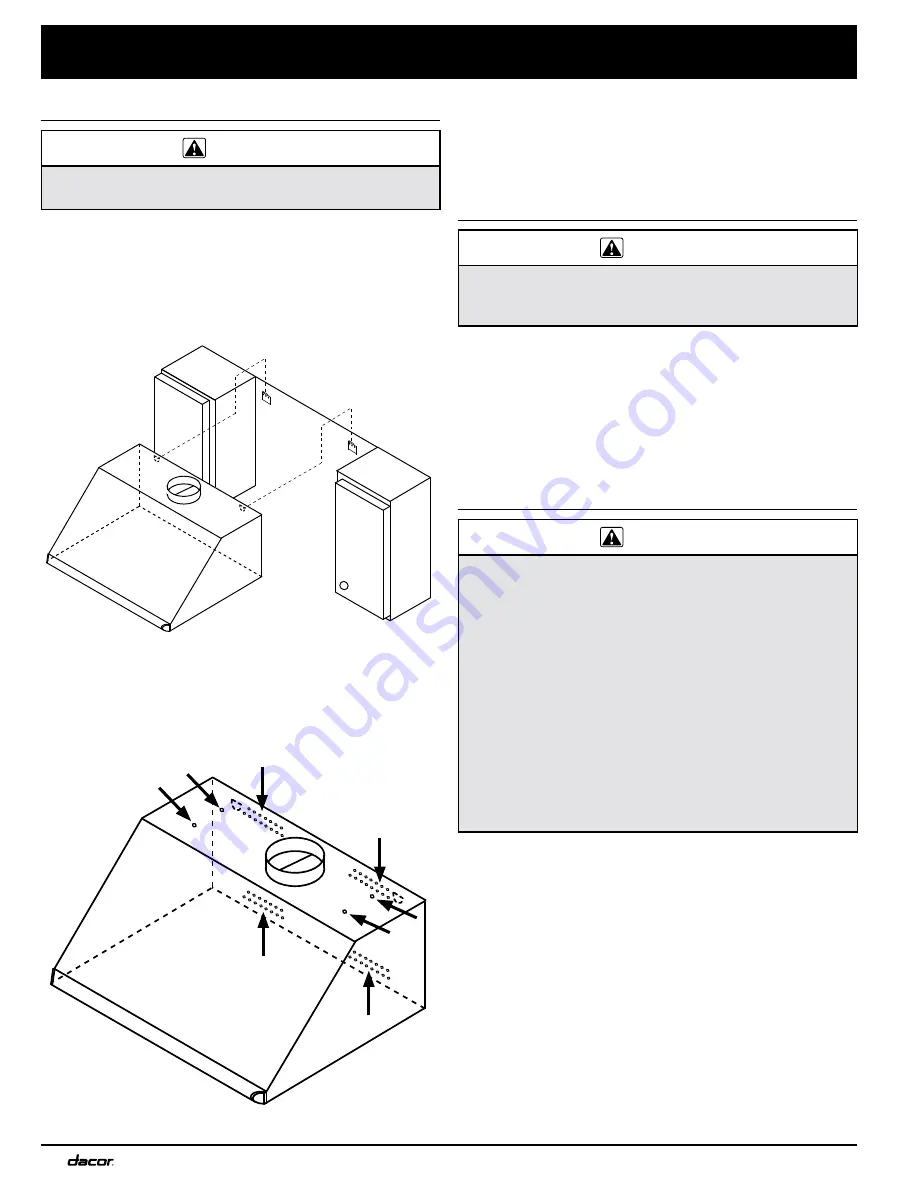

Mounting hole locations

Hanging the Range Hood

wArning

Hanging the range hood requires two people. Do not

attempt to lift the hood without assistance.

Remove the plastic coating from the outside of the

1.

hood.

Remove the filter(s) to reduce weight and avoid dam-

2.

age.

Lift the hood up on both sides and slip the mounting

3.

slots over the tabs on the mounting brackets.

Lift the hood into its final position and mark the desired

4.

locations for the anchors or wood screws through the

mounting slots on the back and top of the hood.

Remove the hood from the wall.

5.

Drill the pilot or mounting anchor holes. If using mount-

6.

ing anchors insert them into the mounting holes.

Reattach the hood to the temporary mounting brackets.

7.

Lift the hood into its final position and fasten it in place.

8.

Insert the fasteners through the mounting slots in the

back and top of the hood into the studs, mounting

blocks or anchors.

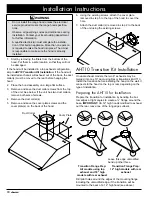

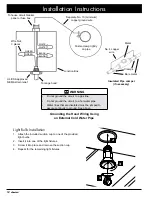

Duct Work Installation

wArning

During duct installation, make sure there are no

obstructions that keep the damper flaps on the top of the

hood from opening.

Install the remote blower according to the remote blow-

1.

er installation instructions.

Install the duct work starting from the hood and working

2.

toward the remote blower. Observe the specifications

on page 7 and 8.

Fasten all joints with sheet metal screws and seal with

3.

duct tape or certified silver tape.

Final Electrical Installation

wArning

To avoid electric shock or fire hazard, prior to con-

•

necting the electrical wiring to the hood, make sure

that power to the hood power supply line is turned off

at the fuse box or circuit breaker panel.

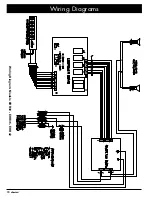

Improper connection of the hood electrical wiring may

•

create an electric shock or fire hazard and may result

in damage to the hood’s electrical system. See page

6 for specifications.

Do not ground the hood to the neutral (white) power

•

supply wire. Connect the hood ground wire to a sepa-

rate, properly grounded wire installed by a licensed

electrician.

Make sure all wire used is capable of handling the

•

total connected load. See page 3.

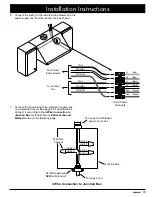

Turn off power to the hood electrical circuit at the circuit

1.

breaker or fuse box.

Run the conduit line used to supply power from the

2.

hood to the remote blower parallel to the duct work.

Wire the remote blower according to the remote blower

3.

or in-line installation instructions.

Connect the conduit to the hood and route the wires to

4.

the terminal block inside the hood.

Route the power supply wiring from the junction box

5.

to the hood. Feed the wiring through the wiring access

holes in the hood and route them to the terminal block

inside the hood.