7

Duct installation requirements for all blowers:

•

All duct work materials (including screws and duct tape)

must be purchased separately by the customer.

•

When planning new duct work, always look for the

shortest, most direct route to the outside. See page

5 for examples.

•

You can increase the duct size over the duct run if

desired. To prevent a back draft, never decrease the

duct size over the run.

•

Do not rely on duct tape alone to seal duct joints.

Fasten all connections with sheet metal screws and

tape all joints with certified silver tape or duct tape.

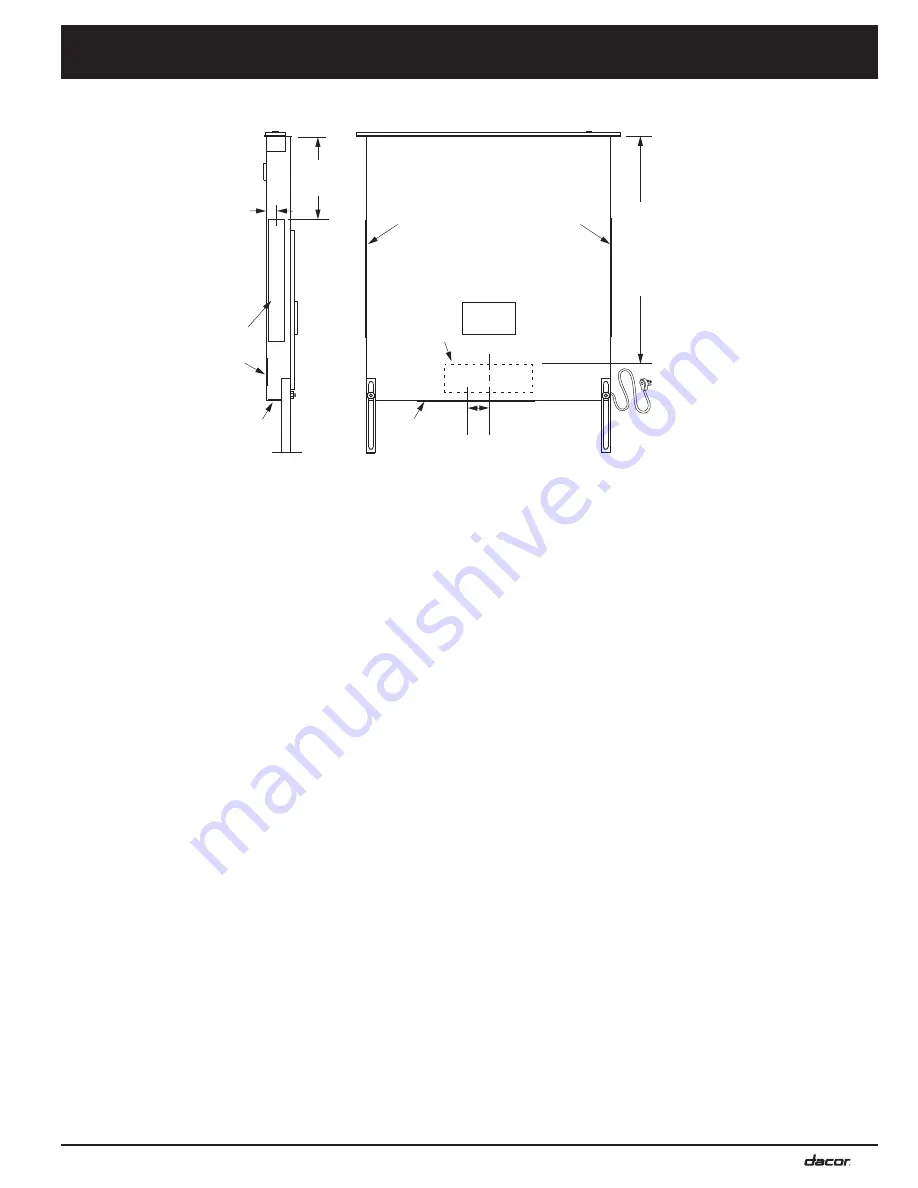

Installation Specifications

Rear exhaust knock-out (3 ¼” x 10”)

3”

Vertical center line of rear exhaust knock out lines up with vertical

center line of chassis

On 46” and 48” wide models, the vertical center line of bottom knock-

out lines up with vertical center line of chassis

On 30” and 36” wide models, the vertical center line of bottom knock-

out is offset 3”

Side exhaust knock-outs (1

5

/

8

” x 16”)

Bottom exhaust knock-out (1

5

/

8

” x 16”)

Motor

cover

Front of unit

26" (66.0 cm)

6 1/4"

(15.9 cm)

1 1/8"

(2.9 cm)

CL

CL

CL

Exhaust Knock-out Locations for Use with

REMP and ILHSF Series Blowers

•

Use sheet metal screws as required to support the duct

weight.

•

To prevent back-drafts, a damper at the duct outlet may

also be required.

•

Make sure duct work does not interfere with floor joists

or wall studs.

•

With concrete slab construction, “box-in” the duct work

and blower wiring to prevent collapsing or other dam-

age when the wet concrete is poured.

•

Cross-drafts or air currents from adjacent open win-

dows or doors, heating/air conditioning outlets, ceiling

fans and recessed ceiling lights reduce vent efficiency.

•

System exhaust location (see page 6) must take

into account accumulated snowfall, where applicable.

Summary of Contents for ERV3015

Page 18: ...16 Notes ...

Page 19: ...17 ...