33

English

Installation Instructions

Verifying Proper Operation

Before operating the range, read the User Manual completely to familiarize yourself with important safety,

service, and warranty information.

1.

Turn off all burners, and verify that all burner compo-

nents are properly assembled.

2.

Open the gas-supply valve, and verify that there are no

gas leaks.

3. Turn on power to the range at the power source.

4.

Follow the prompts on the oven display to establish user

preferences and wireless-network settings.

5.

On the display, touch MENU > BAKE.

The default bake temperature appears on the display.

6. Touch Start, and wait 3 minutes.

7.

Open the door to verify that the oven is heating.

BAKE and the preheating temp appear on the display.

8.

Touch CANCEL-SECURE or CANCEL RIGHT (48” models).

The oven's heating elements turns off.

9. Push-turn a burner-control knob to maximum flame.

Shortly, the burner ignites, and the ignitor stops sparking.

If the burner does not ignite in 4 seconds, turn it off, wait

5 minutes for gas to dissipate, then try again.

10. Turn the knob from max to minimum flame, observing

the flame as the knob turns.

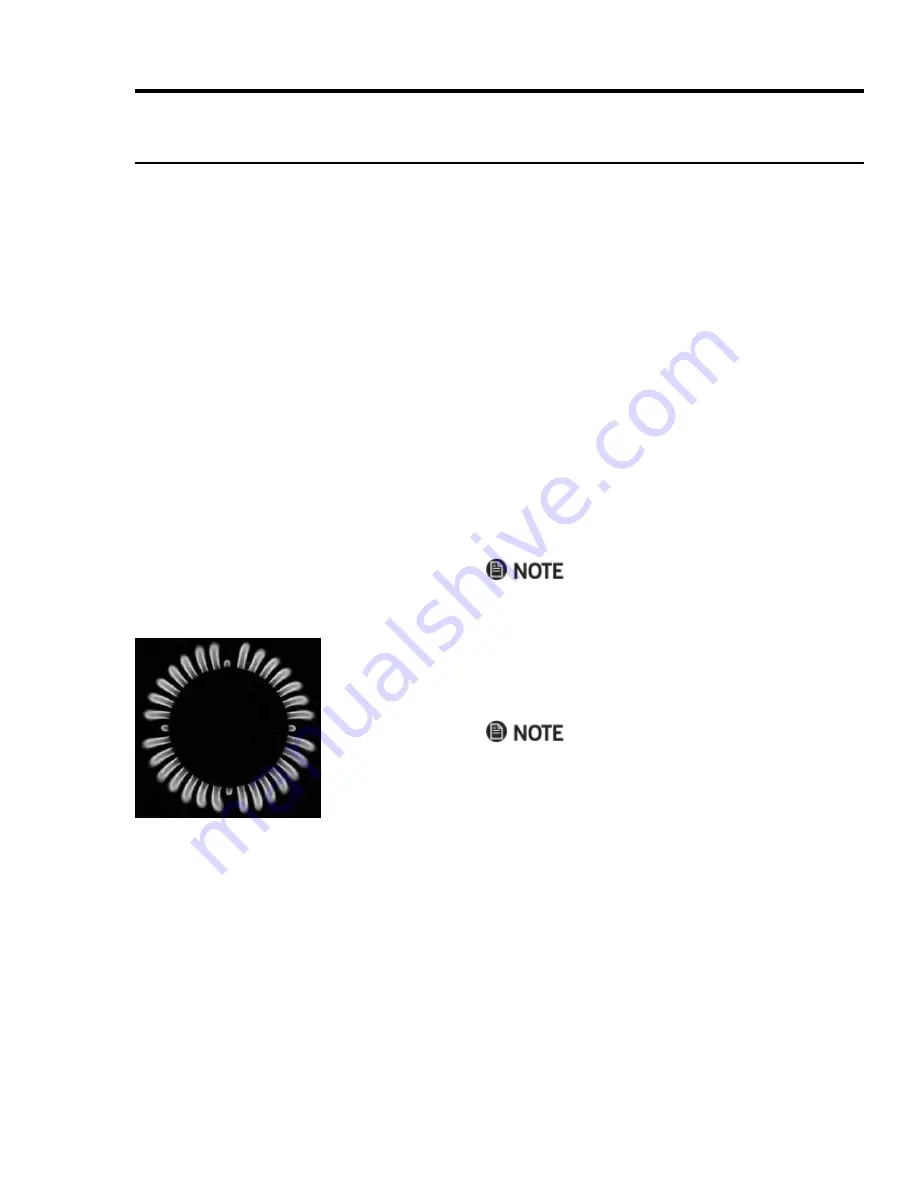

A proper flame is steady and quiet, with a sharp, blue

inner cone that varies in length with the burner size.

Dacor’s Smart Flame™ feature reduces the flame under

the grate fingers to increase grate life. If the range is

equipped for LP gas, normal flame tips may be yellow.

11.

Turn off the burner, and run the test for the other burners.

Proper

Flame