13

English

Installation Requirements

Pre-Installation Checklist

1. Before installing the range, read this manual thoroughly.

2. Plan for a location where the range will not be subject to strong drafts.

3. Remove packaging, grate boxes, regulator with literature, and literature package from the range, verify

that all items are present before beginning the installation.

General Requirements

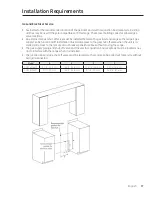

Clearances and Dimensions

• For over-the-range (OTR) over gas stove, follow the local gas code.

• For safe operation, provide adequate space between the range and combustible surfaces. Location of the

electrical outlet and gas piping may be adjusted to meet the dimensions and clearances in this manual.

•

The range may be installed flush to the rear wall. A non-combustible material must be installed on the rear

wall between the range and hood. It is not necessary to install non- combustible material directly behind

the range. Openings in the wall behind the range or in the floor below must be sealed.

• Canada only: A free-standing range shall be installed at least 4.7 in. (12 cm) from all adjacent surfaces.

The range complies with the maximum allowable wood-cabinet temperature of 194 °F (90 °C).

Ensure the adjacent wall covering, countertops, and cabinets can withstand such heat to avoid discoloration,

delamination, or melting.

Minimum Dimensions

Regarding overhead cabinets, a hood should be installed that projects at least 5" (12.7 cm) beyond the cabin-

etry face to dissipate heat in those cabinets. The hood must consist of sheet metal at least .0122" thick. Install

the hood with at least 1/4" clearance between it and the bottom of the combustible material or metal cabinet.

The hood must be at least as wide as the range and centered over it. Clearance between the cook surface and

hood bottom must be at least 24". (For above-range cooking appliances, follow that appliance's installation

criteria.)

• 30" (76.2 cm) minimum clearance between the cook surface and bottom of an unprotected wood/ metal

cabinet; or if no 30" (76.2 cm) min. clearance, 24" (61 cm) min. when the bottom of the wood/metal cabinet

is protected by at least .25" (.64 cm) flame-retardant millboard covered with at least No. 28 MSG sheet

steel, .015" (.038 cm) stainless steel, .024" (.061 cm) aluminum, or .02" (.051 cm) copper.

• 18 in. (45.7 cm) minimum between the countertop and adjacent cabinet bottom.