- 4 -

K9 2400

K9 2440

2. GENERAL SAFETY INFORMATION

This symbol means ATTENTION!

YOUR SAFETY IS INVOLVED.

The message that follows the sym-

bol contains important information

about safety. Carefully read the mes-

sage.

BEFORE SERVICING AND REPAIRING

1. Read all safety instruction in this manual and

be aware of safety decal locations on your

machine.

2. Thoroughly clean your work area and the

machine.

3. Make sure the machine is on firm and level

ground and that the parking brake is set.

4. Lower the implement to the ground.

5. Stop the engine and remove the key.

6. Disconnect the negative battery cable.

7. Place a "DO NOT OPERATE" tag in the

operator station.

WORKING SAFETY

1. Do not operate or service the machine while

under the influence of alcohol, medications,

or other sustances.

2. Never wear loose fitting clothing and always

use safety equipment appropriate to the job.

3. Never use improvised tools, parts or

procedures. Use only recommended tools

appropriate to the work.

4. Extra care should be taken to work safely

when servicing is done by two or more

persons.

5. Always support the machine with safety

stands rated for the weight of the machine.

Never work under a machine that is

supported solely with a jack.

6. Do not touch any rotating or hot parts while

the engine is running.

7. Escaping fluid (hydraulic oil) under pressure

can penetrate the skin causing serious

injury. Relieve pressure before disconnecting

hydraulic or fuel lines. Tighten all connections

before applying pressure.

DISPOSE OF FLUIDS PROPERLY

1. Observe relevant environmental protection

regulations when disposing of oil. NEVER

pour fluids onto the ground, down a drain, or

into any body of water.

3. INSTALLATION INSTRUCTION

1. Park the vehicle on firm and level ground.

Then, engage the parking brake and stop the

engine.

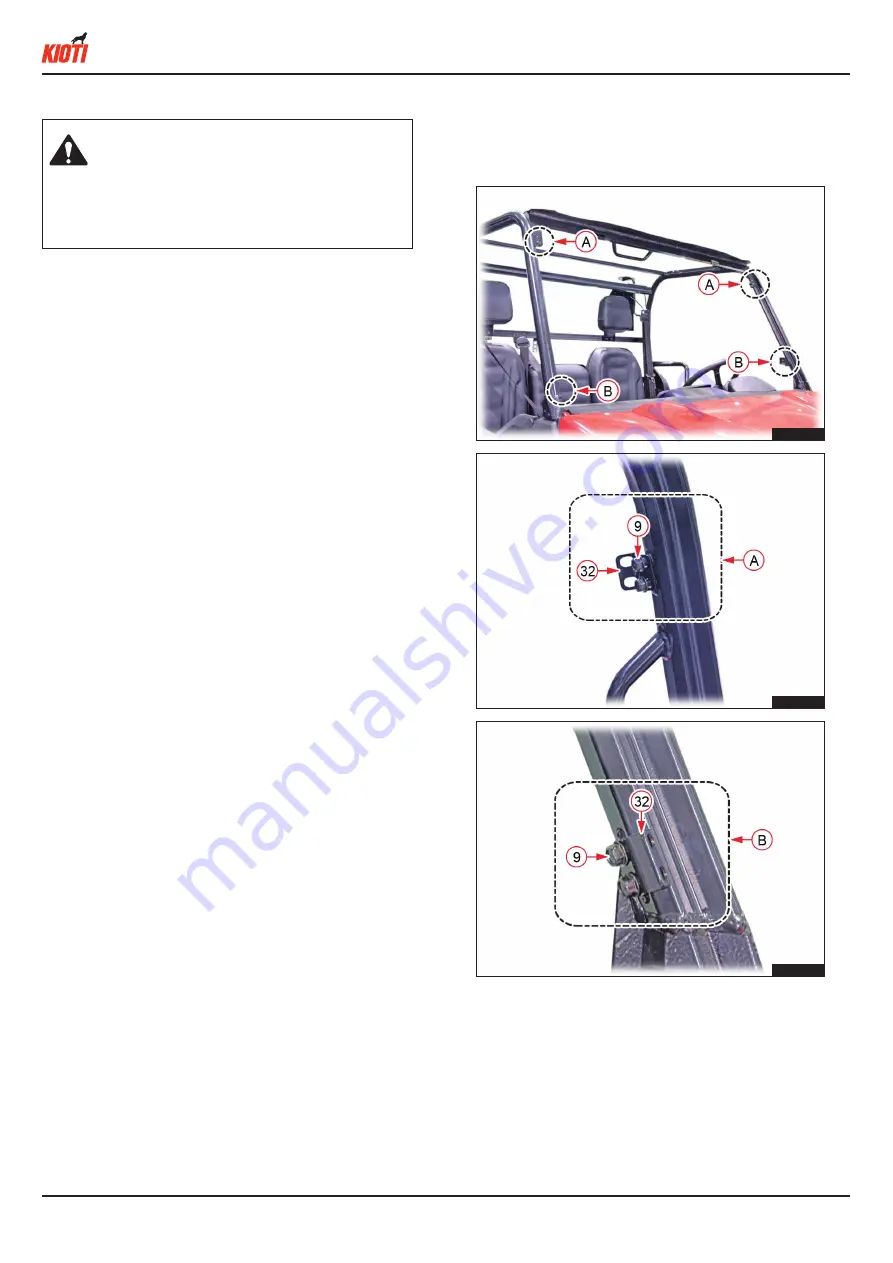

2. Install each upper frame stay (32) (4 EA) to

the left / right side of the ROPS front frame

and tighten the flange bolt (9).

U20SH02A

U20SH34A

U20SH34A