Black Bear is a registered trademark of Daekyung Co., Ltd.

1521-6 Dadae-dong, Saha-gu, Busan, Korea Tel: +82)51-264-6611 Fax: +82)51-264-6615

BLACK BEAR HOIST

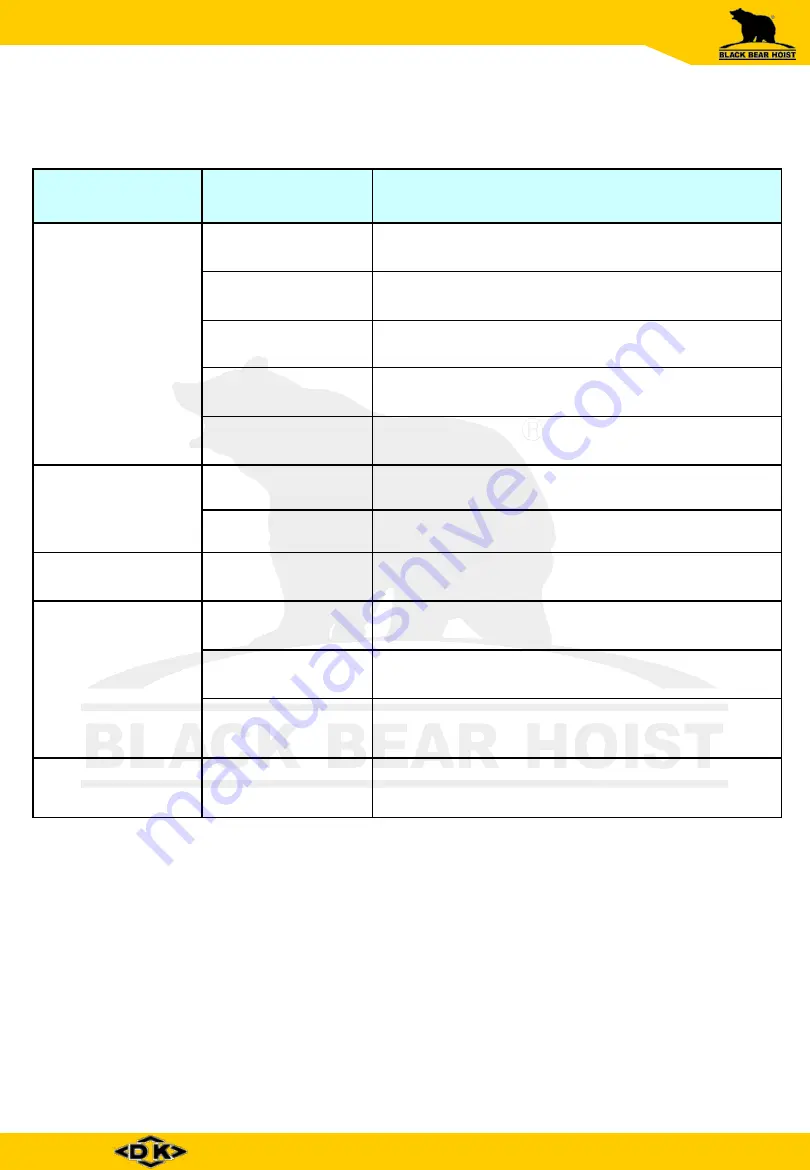

7.3 Check List

Part

Check List

Check Standard

Body

Exterior Appearance

There should not be any rust, dent, or damage.

Noise

There should not be any unusual or excessive noise.

Side Plate

There should not be any dent, abrasion or deformation.

Reduction Gear

There should not be any dent, abrasion or deformation.

Load Sheave

There should not be any dent, abrasion or deformation.

Load Chain

Rust/Dent

There should not be any rust, dent, or deformation.

Oil Lubrication

Oil must be thoroughly and evenly distributed.

Top & Bottom Hook

Deformation

Hooks should not be deformed (sagging or cracked open).

Hook

Holder

There should not be any dent, abrasion or deformation.

Bottom Hook Pin

There should not be any abrasion or bending.

Safety Latch

Safety Latch must be in place and it should move freely.

Other

Hand Chain

Hand chain must operate smoothly.

- 20 -