●

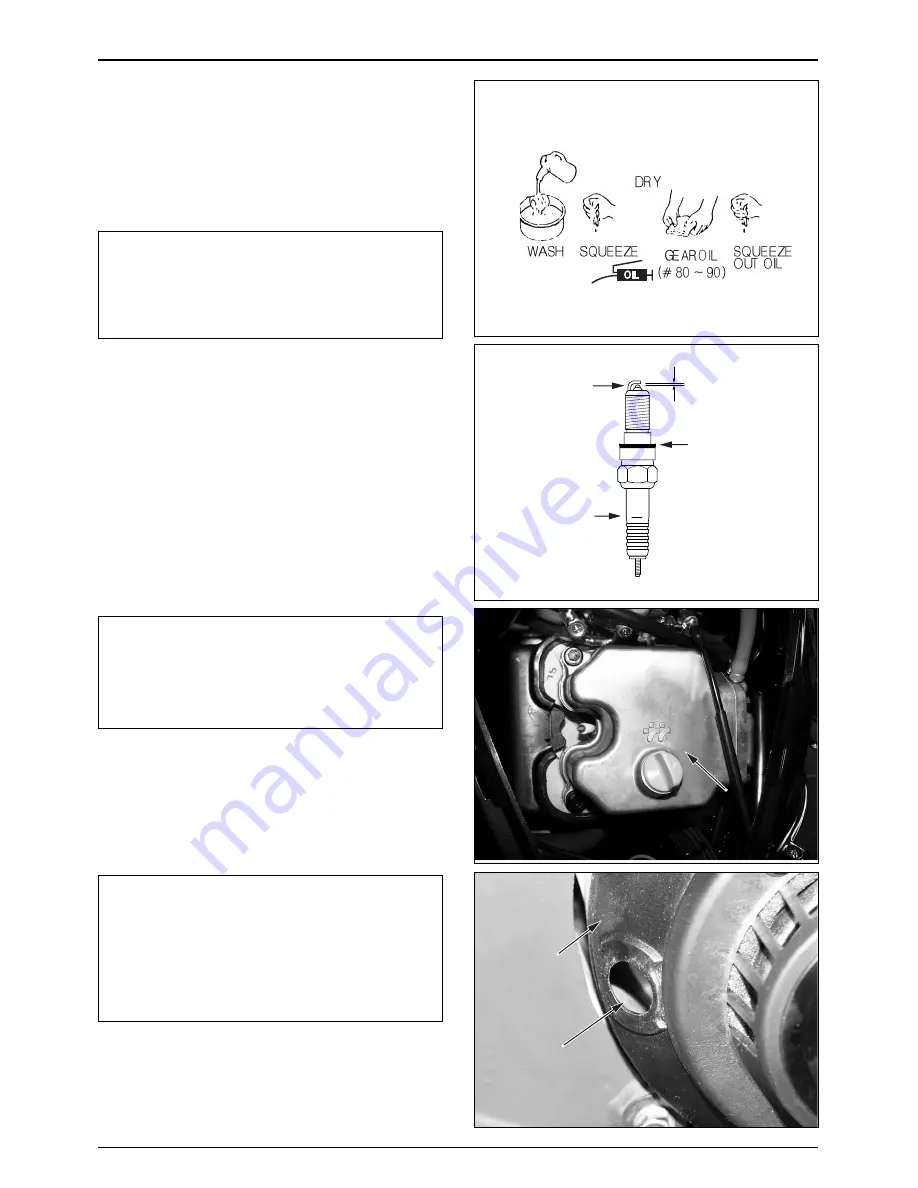

Be sure to allow the element to dry thoroughly before

applying oil. Otherwise, the oil will be diluted by the

and the filtering ability of the filter will be much less

effective.

●

Spread clean #80~90 gear oil on the element, rubbing

inthoroughly over the surface with both hands, and then

squeeze out any excess oil.

CAUTION

•

Using air filter oil when riding in extremely dusty

conditions prevents premature engine wear due to

dust/dirt drawn into the engine. Apply air filter oil to

the entire surface of the element and rub it with both

hands to saturate the element with oil. Squeeze out

excess oil.

SPARK PLUG

●

Remove the plug maintenance cover.

●

Remove the spark plug cap and disassemble the plug.

●

Check the plug for damage, contamination or deposits.

●

If the spark plug is severely contaminated or damaged,

raplace with a new one. If the plug can be reused after

removing only the carbon, use plug cleaner and wire

brush to clean the plug.

●

Always use a feeler gauge to check the gap.

GENUINE PLUG : CR8EH-9

SPARK PLUG GAP : 0.8~0.9mm

TORQUE VALUE : 1.1 kgf

·

m

CAUTION

•

Make sure there is no dirt or debris on the seat of the

spark plug hole before inserting the spark plug.

•

To prevent damage to the cylinder head, hand-tighten

the spark plug before using a wrench to tighten to the

specified torque.(torque : 14kgf

·

m)

•

Do not overtighten the spark plug.

VALVE CLEARANCE

●

Remove the following parts.

-Luggage box.

(

⇨

4-4)

-Center cover.

(

⇨

4-5)

●

Loosen the 4 cylinder head bolts.

NOTE

•

Inspect and adjust the valve clearance when the

engine is cool. (under 35

°

C / 95

°

F)

•

Remove the cylinder head cover.

•

Turn the flywheel counterclockwise, and align the

“

T

”

mark on the flywheel with the index mark on

the RH. crank case cover.

•

The piston at this time must be at the top dead center

of the compression stroke.

●

Measure valve clearance with a feeler gauge.

VALVE CLEARANCE : Intake : 0.12

±

0.02mm

Exhaust : 0.12

±

0.02mm

3-5

INSPECTIONS / ADJUSTMENTS

TIMING CHECKING

RH. SHROUD

CHECK GAP,

DEPOSITS

CHECK FOR

CRACKS

CHECK WASHER

FOR DAMAGE

0.8mm~0.9mm

CYLINDER HEAD

COVER

→

→

→

Summary of Contents for HISTORY 125 - SERVICE

Page 1: ......

Page 28: ...MEMO...

Page 51: ...MEMO...

Page 52: ...FUEL SYSTEM 5 0 FUEL TANK FUEL STRAINER FUEL PUMP CARBURETOR...

Page 66: ...7 0 LH CRANKCASECOVER KICKSTARTER CONTINUOUSLYVARIABLE TRANSMISSION LH CRANKCASE COVER...

Page 83: ...MEMO...

Page 84: ...8 0 FLYWHEEL STATOR COMP RH SHROUD COOLING FAN A C GENERATOR STARTER CLUTCH...

Page 93: ...MEMO...

Page 110: ...10 0 CYLINDER PISTON CYLINDER CYLINDER GASKET PISTON TOP RING SECOND RING OIL RING...

Page 117: ...MEMO...

Page 118: ...11 0 TRANSMISSION CRANKSHAFT CRANK CASE RH CRANKCASE LH CRANKCASE CRANKSHAFT...

Page 129: ...MEMO...

Page 157: ...MEMO...

Page 158: ...BRAKE SYSTEM 14 0...

Page 170: ...MEMO...

Page 178: ...MEMO...

Page 186: ...MEMO...

Page 207: ...SERVICEMANUAL 2001 11 PRINTED 2001 11 PUBLICATION NO COPY...