5-7

FUEL SYSTEM

FLOAT LEVEL INSPECTION

●

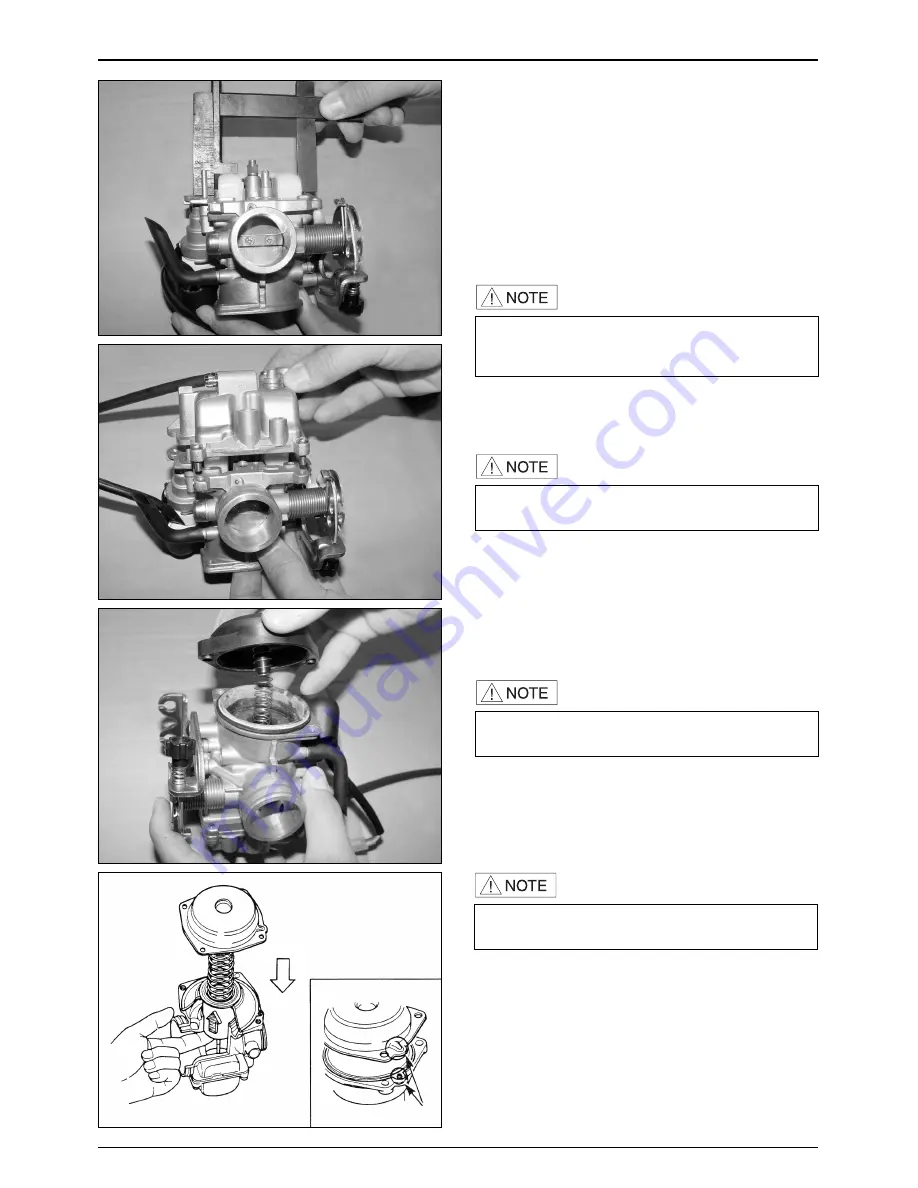

Install the float valve, float, float pin.

●

Measure the float level with the float level gauge.

FLOAT LEVEL : 13 mm

TOOL : FLOAT LEVEL GAUGE

●

If the level is out of specification and the float arm lip

can be bent, adjust the float level by bending the lip.

Non-adjustable floats must be replaced.

●

Insert the jet needle, needle spring holder, needle

spring, diaphragm assembly, and install the needle

screw.

●

Install the diaphragm assembly on the carburetor body.

●

Install the diaphragm spring.

●

Install the diaphragm cover with its cutout aligned with

the hole in the tab of diaphragm.

●

Install the auto bystarter wiring plate to the diaphragm,

and tighten the 4 pan screws.

●

Install the drain tube and air-hose.

●

Install the float body assembly, install the bracket and 4

pan screws.

•

Be sure to keep the float level at the specified height.

If the float level is low / high, fuel mixture becomes

lean / rich.

•

Be sure to replace the float chamber body O-ring

with the new one.

•

Install the jet needle aligned with the grooves in the

diaphragm.

•

Be careful not to pinch the diaphragm, and to keep

the spring straight.

COMPRESS STRAIGHT

ALIGN

Summary of Contents for S2 125

Page 1: ......

Page 3: ......

Page 21: ...MEMO...

Page 49: ...MEMO...

Page 59: ...MEMO...

Page 63: ...7 0 LH CRANKCASECOVER CONTINUOUSLYVARIABLE TRANSMISSION LH CRANKCASE COVER...

Page 77: ...8 0 A C GENERATOR STARTER CLUTCH FLYWHEEL STATOR COMP RH SHROUD COOLING FAN...

Page 86: ...MEMO...

Page 103: ...10 0 CYLINDER PISTON CYLINDER CYLINDER GASKET PISTON TOP RING SECOND RING OIL RING...

Page 110: ...MEMO...

Page 111: ...11 0 TRANSMISSION CRANKSHAFT CRANKCASE RH CRANKCASE LH CRANKCASE CRANKSHAFT...

Page 122: ...MEMO...

Page 144: ...MEMO...

Page 145: ...13 0 REAR WHEEL BRAKE SUSPENSION REAR SWING ARM...

Page 154: ...MEMO...

Page 168: ...MEMO...

Page 177: ...MEMO...

Page 183: ...SERVICEMANUAL 2004 11 PRINTED 2004 11 PUBLICATION NO COPY...